Die-cutting makes uses of a sharp steel blade fashioned into a particular shape. Using special machinery, you create a smooth, crisp edge with a specific, consistent finish. One way to think of it is as industrial-grade cookie cutting.

There are almost no limits to the possible shapes you can have, since the cut form or ‘die’ is specifically customised for each job. And it’s that ability to create such specific shapes that can really set your brand apart.

When people ask about the difference between digital cutting and die-cutting, we like to point out that both can be done on smaller or larger scales, although if you’re working in a large format such as retail branding or signage, large format digital cutting tends to work best.

PROS OF DIE-CUTTING

Traditional die-cutting does bring with it a number of benefits, including:

Die-cutting means less material is wasted around the shapes than with other cutting methods, clearly, this is not only cost-effective but is better for the environment as well

With only one machine needed, the process is generally cost-effective and efficient in terms of how much time it takes

A die cutting machine can fashion shapes with a single punch so that identical forms can be made very quickly – even a manual die cutter makes shapes more quickly than any alternative method

You can achieve pretty complex shapes, with multiple cuts and multiple layers

Die-cutting allows for creative shapes that look terrific, and for creases in cards and plastic

DISADVANTAGES OF DIE-CUTTING

However, there are also some potential drawbacks to the process of die-cutting, which you need to appreciate:

Because the cutting tool incorporates a sharp blade, it can be dangerous unless the person completing the task really knows what they are doing

You will need a new die for each design you create

It is less cost-effective if you are not using this technique that often and only need low volume

It may not be the method of choice if you are working with thicker materials

Length, height and width are subject to the limitations of the rotary machine, so if you want large-format printing such as office signage or retail branding, it may not be ideal

WHAT IS DIGITAL CUTTING?

This technique allows for precision cutting without the use of dies via a computer-programmed path. Using this method, you get all the advantages of traditional die-cutting, but with the use of lasers to allow for a precision cut, along with creases and scores as required.

A huge range of materials can be cut using this process. And you can use digital cutting for smaller-scale projects, but it really comes into its own with large-format printing and jobs such as stand-out signage and similar graphic installations.

These days, those using digital cutting often work with innovative machines like the state-of-the-art Zund model allowing us to produce large-format digital printing up to 5m in size.

PROS OF DIGITAL CUTTING

As you would expect, there are a number of solid benefits to using this modern technique for pattern cutting. Here are some of them:

Because of the speed at which digital cutting machines can operate, turnaround and overall production times tend to be shorter. This is not least because there is no need to change die shapes.

It’s hard to beat the extremely high levels of clean precision you get with digital cutting, thanks to the use of the laser.

Digital cutting can also work with a number of software programmes, and once you have settled on a particular machine, it’s generally straightforward to integrate the software you need.

The range of materials used in digital cutting can include vinyl, leather, cardboard, composite materials and foam boards, so you can work with thicker items.

As mentioned above, digital cutting is ideal if you need large-format printing and bigger graphic installations.

DISADVANTAGES OF DIGITAL CUTTING

There can be a number of these, as well, as including:

For a high volume of smaller, paper-printed items, you could save time and money with a traditional die-cutting technique.

Energy consumption can be high.

The cost of putting together a custom die can be offset by using it across a large volume of items, including for future print runs.

WHICH OF THE TWO METHODS IS BETTER?

It honestly depends on what you need, so it isn’t really a case of digital cutting vs. die-cutting, or which one is best, but which one best suits what you’re aiming to achieve. For low-volume, large-format printing using tougher, thicker materials, digital cutting will mean no need to pay for a custom die, and the possibility to create more intricate shapes. However, if it’s a high volume of thinner materials you need, die-cutting is more time and cost-efficient.

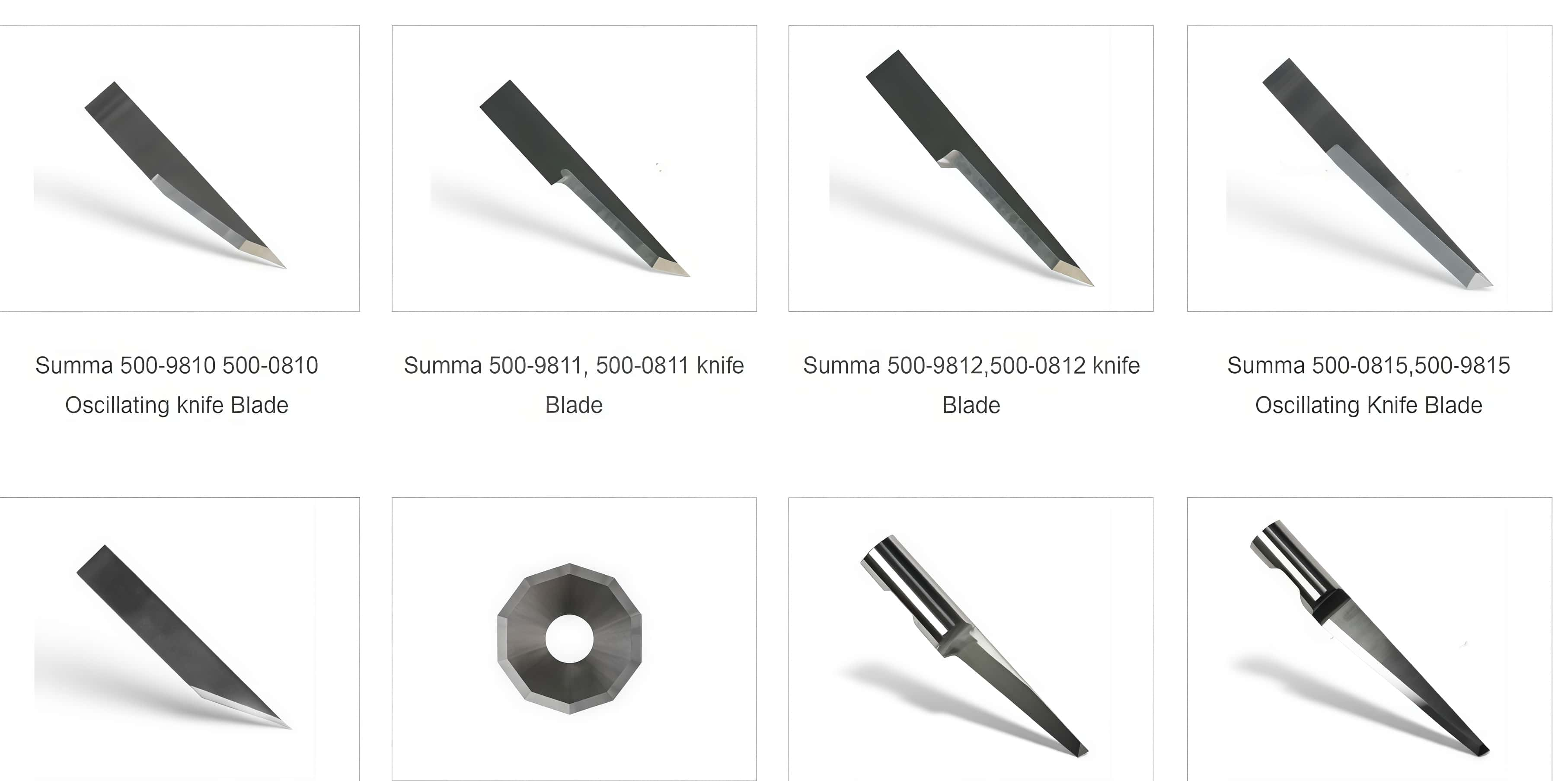

Shenzhen Oyea Machinery Co., Ltd. production Aristo Axyz Atom Benz Blackman & White Bullmer Comagrav CombiPro Data Technology DRD Dierre Dyss Ecocam Elcede Elitron Esko Kongsberg Gerber Graphtec Gunnar Haase iEcho Science & Technology JWei Kasemake Krause Kuris RuiZhou Ronchini Lasercomb Protek Marbach Mécanuméric Mimaki Misomex Multicam RolandSei Summa Valiani Wild Zund...Tungsten Steel Blades

PREV : What materials are best suited for the ZUND Z16 blades? Specifications and dimensions NEXT : Introduction Of The Performance Of Tungsten Steel Blades