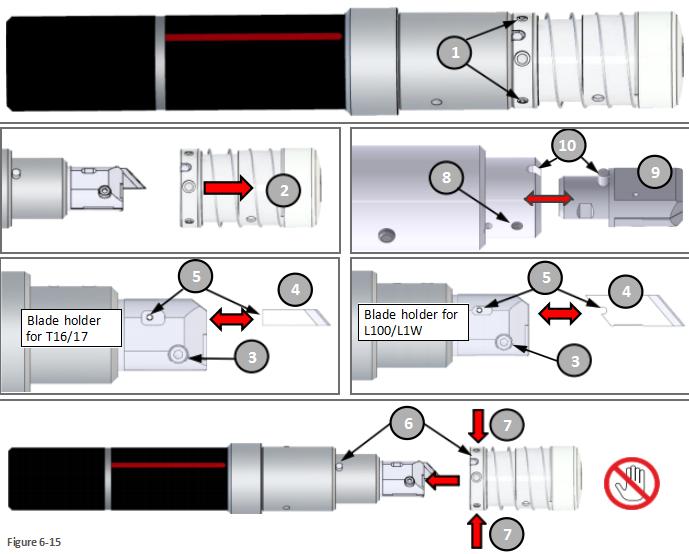

TANGENTIAL TOOL PREPARATION

DANGER: Use protective gloves is strongly recommended, be very careful as the pressure of the moving part (2) could cause the blade exit.

To mount or replace the blade holder, proceed as follows:

Note: Depending on the blades being used for the desired processes, the relative dedicated blade holder must be mounted (blade holder for L100 / L1W blades or blade holder for flat blades T16 / 17).

a) Loosen the locking set screws (1) and remove the movable blade guard (2)

Attention: If a blade holder equipped with a blade is already present on the tangential tool, first proceed with the disassembly of the latter in order to avoid possible accidental injuries (carryout point (e) and then resume the procedure from point b).

b) Loosen the set screw (8) and extract the blade holder (9).

c) Insert the desired blade holder with the reference pin (10) oriented as shown in the figure and make sure that it is entered up to the stop.

d) Tighten the set screw (8).

e) Loosen the blade cartridgescrew (3) and remove the used blade (4) (if present) .

f) insert a new blade (4) until the notch of blade reaches the pin (5), then tighten the screw (3).

g) Position the blade guard so that the reference pin matches its housing (6), then grab it from the sides (7) and push it towards the tool.

Attention: while inserting the blade protection, pay attention the palm of your hand is not positioned in front of the tool as indicated by the prohibition symbol.

h) Tighten the locking set screws (1).

To replace a blade, carryout the procedure described above, skipping points b) c) d).

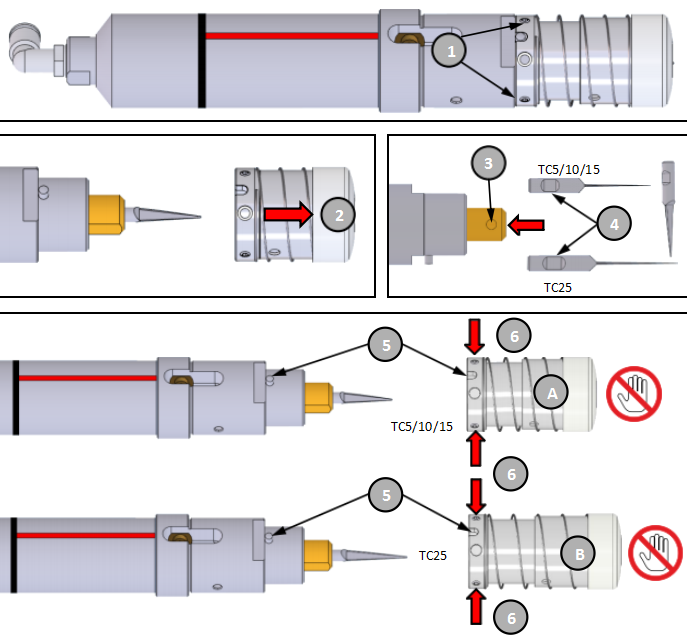

OSCILLATING CUTTING TOOL PREPE RATION (OPTIONAL)

DANGER: Use protective gloves is strongly recommended, be very careful as the pressure of the moving part (2) could cause the blade exit.

• Loosen the locking set screws (1) and remove the movable blade guard (2).

• Loosen the blade holderscrew (3) and insert a new “TC” Type blade, paying attention that the blade notch (4) matches the locking screw and then push it inside until to the stop and tighten the screw (3).

• Position the blade guard (A) or (B), depending on whether we have chosen a TC5/10/15 or TC25 type, paying

attention that the reference pin fits into its housing (5), then grab it from the sides (6) and push it towards the tool.

Attention: while inserting the blade protection, pay attention the palm of your hand is not positioned in front of the tool as indicated by the prohibition symbol.

• Tighten the locking set screws (1).

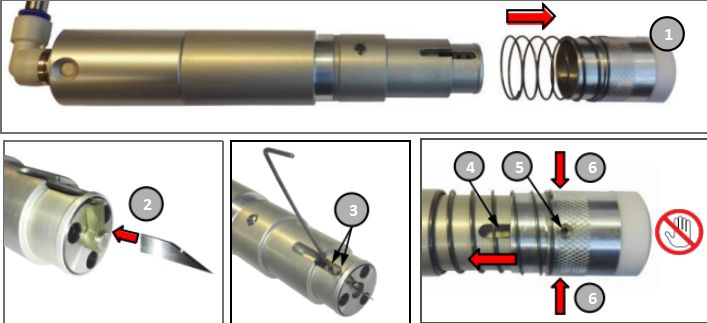

X TYPE OSCILLATING TOOL PREPARATION (OPTIONAL)

DANGER: Use protective gloves is strongly recommended, be very careful as the pressure of the moving part

(2) could cause the blade exit.

Remove the blade guard (1) by pulling it outwards.

• Insert a flat blade into its housing with the tip facing the center of the tool (2).

• Tighten the two blade locking set screws (3) with a 1.5mm Allen key

• Position the blade guard so that the reference pin (4) matches the sliding slot (5), then grab it from the sides (6) and push it towards the tool.

Attention: while inserting the blade protection, pay attention the palm of your hand is not positioned in front of the tool as indicated by the prohibition symbol.

PREV : Which Vinyl Cutting Blade Should You Use? How To Choose A Plotter Blade? NEXT : Summa / Valiani Kiss-Cut Tool - Kct,Knives For Summa Cutting Plotter