Introduction

In many fields of modern industrial production and daily life, the use of cutting tools is ubiquitous, and the quality of their performance directly affects the efficiency and quality of work. As a cutting tool with unique performance, Hard Metal (Hm) Carbide Oscillating Knife Blade is gradually emerging in the market. With its special material and design, it can meet the cutting needs under various complex working conditions and provide strong support for the development of different industries.

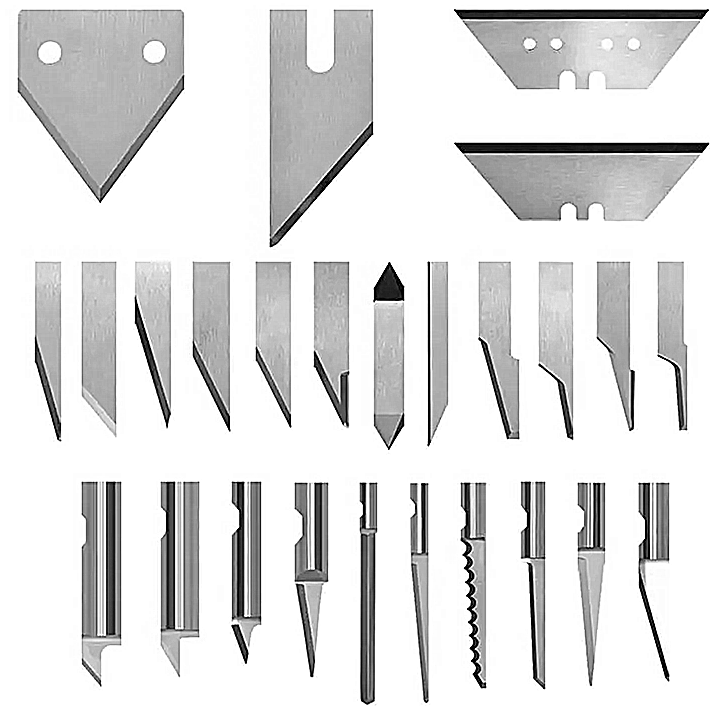

Basic Overview of Hard Metal (Hm) Carbide Oscillating Knife Blade

Definition and Structure

Hard Metal (Hm) Carbide Oscillating Knife Blade is an oscillating blade made of hard alloy (Hard Metal). Hard alloy is an alloy material made of hard compounds of refractory metals and bonding metals through powder metallurgy process, with excellent properties such as high hardness, high strength and wear resistance. The structural design of this blade usually includes two parts: the body and the blade. The body generally has a specific shape and size to adapt to different oscillating tools; the blade is specially processed and treated to have a sharp cutting edge, which can efficiently complete the cutting task.

Working principle

The working principle is based on oscillating motion. When the blade is installed on the oscillating tool, the tool will generate high-frequency oscillating motion, causing the blade to reciprocate rapidly in a short time. This oscillating motion is different from the traditional rotary or linear cutting method. It can generate a larger cutting force in a smaller space, thereby achieving efficient cutting of various materials. For example, when cutting some soft but tough materials, the oscillating motion can better overcome the resistance of the material and make the cutting smoother.

Performance advantages of Hard Metal (Hm) Carbide Oscillating Knife Blade

High hardness and wear resistance

The carbide material gives this blade extremely high hardness, allowing it to easily cut materials with higher hardness, such as metals, ceramics, etc. At the same time, its excellent wear resistance ensures that the blade will not wear easily during long-term use, extending the service life of the blade. Compared with ordinary knives, the wear resistance of Hard Metal (Hm) Carbide Oscillating Knife Blade can be improved several times or even dozens of times. For example, in some continuous cutting operations, ordinary knives may need to be replaced after a few hours of use, while this carbide oscillating blade can be used continuously for several days or even longer, greatly reducing production costs.

High cutting accuracy

Due to its oscillating motion characteristics, Hard Metal (Hm) Carbide Oscillating Knife Blade can achieve very precise cutting. In some industries that require extremely high cutting accuracy, such as electronic manufacturing, precision instrument processing, etc., this blade can meet the cutting needs of small sizes and complex shapes. For example, when cutting electronic circuit boards, it is necessary to accurately cut out the shapes of various circuits and components. Hard Metal (Hm) Carbide Oscillating Knife Blade can rely on its high-precision cutting performance to ensure the accuracy of cutting dimensions and the flatness of the edges, thereby improving the quality and performance of the product.

Strong adaptability

The blade can adapt to a variety of different materials and working conditions. Whether it is cutting soft materials such as wood, plastic, rubber, or hard materials such as metal and stone, it can achieve good cutting results. In different working environments, such as high temperature, humidity, dust and other harsh conditions, Hard Metal (Hm) Carbide Oscillating Knife Blade can also maintain stable performance and work normally. For example, in construction, it is necessary to cut pipes and plates of various materials. This blade can efficiently complete the cutting task in different construction site environments.

Application fields of Hard Metal (Hm) Carbide Oscillating Knife Blade

Industrial manufacturing field

In industrial manufacturing, Hard Metal (Hm) Carbide Oscillating Knife Blade is widely used in the processing and manufacturing of various parts. For example, in the automobile manufacturing industry, it can be used to cut automobile interior materials, rubber seals, etc.; in the mechanical processing industry, it can be used to cut metal plates, pipes, etc. Its high hardness and high precision can ensure the quality and dimensional accuracy of processed parts and improve production efficiency. According to statistics, in some large automobile manufacturing companies, after using this blade, the processing accuracy of parts has increased by 10% - 20%, and the production efficiency has increased by 15% - 25%.

Electronic information field

With the rapid development of the electronic information industry, the processing accuracy and quality requirements of electronic components are getting higher and higher. Hard Metal (Hm) Carbide Oscillating Knife Blade plays an important role in the field of electronic information. It can be used to cut tiny parts such as circuit boards and chip packaging materials to ensure the performance and reliability of electronic components. For example, in the production process of electronic products such as smart phones, circuit boards need to be accurately cut and processed. This blade can meet its high-precision cutting needs and ensure the quality and stability of the product.

Home decoration field

In the home decoration industry, Hard Metal (Hm) Carbide Oscillating Knife Blade can be used to cut various decorative materials, such as wood, plastic sheets, carpets, etc. Its high cutting accuracy and strong adaptability can meet the cutting needs of different shapes and sizes in home decoration, making the decorative effect more beautiful and exquisite. For example, when making custom furniture, wood needs to be precisely cut and spliced. This blade can help craftsmen achieve complex design and process requirements and improve the quality of furniture.

Shenzhen Oyea Machinery Co., Ltd. provides manufacturing and sales Atom Zund Comelz Esko Teseo Aristo Elitron Summa Axyz Ecocam Multicam Lectra Gerber MimakHard Metal(Hm )Carbide Oscillating Knife Blade

PREV : Summa Aristo Gerber Esko Roland Zund Knives And CNC Knife Blades Are Widely Sold And Distributed NEXT : Atom Kimla Polska Grupa Cnc Seron Tungsten Steel Blade Compatibility Replacement Applicable