Selecting the appropriate cutting tools and blades for your Zund cutting system is essential to achieve optimal performance and precision. Zund offers a modular system that allows for a wide range of tooling options, enabling customization based on specific materials and applications. Here's a guide to help you choose the right tools and blades:

1. Understand the Modular Tooling System:

Zund's cutting systems utilize modules that can be equipped with various tools, each designed for specific tasks:

- Universal Module (UM): Compatible with a variety of tools, including:

- Universal Cutting Tool (UCT): Ideal for materials up to 5 mm thick.

- Electric Oscillating Tool (EOT): Suitable for soft to medium-density materials.

- Kiss-Cut Tool (KCT): Designed for precise kiss-cutting of vinyl and film without damaging the liner material.

- V-Cut Tool (VCT): Used for creating V-cuts in materials like corrugated cardboard and foam boards at various angles.

- Router Modules (RM): For routing, polishing, and engraving tasks:

- RM-L:Features a powerful 3.6 kW spindle for high-precision routing of materials like aluminum, wood, plastics, and composites.

- RM-A: Equipped with a 1 kW spindle suitable for various routing applications.

- RM-S: An air-cooled module with a 1 kW spindle, ideal for lighter routing tasks.

- Punching Modules:

- Notching Marking Module (NMM): Combines punching, notching, and marking tools.

- Punching Pricking Module (PPM-S): Suitable for punching and piercing leather, rubber, and textiles.

2. Identify the Material and Application:

The choice of tool and blade depends on the material you're processing and the desired outcome:

- Drag Blades: Used in non-powered tools like UCT and KCT, suitable for cutting foil, paper, thin folding cartons, banners, etc.

-Oscillating Blades: Used in EOT and POT tools, ideal for cutting thick and tough materials.

- Rotary Blades: Used in DRT and PRT tools, suitable for cutting breathable materials such as textiles, carbon fiber, glass fiber, etc.

3. Consult Blade Compatibility:

Ensure that the blade you select is compatible with the chosen tool and suitable for the material:

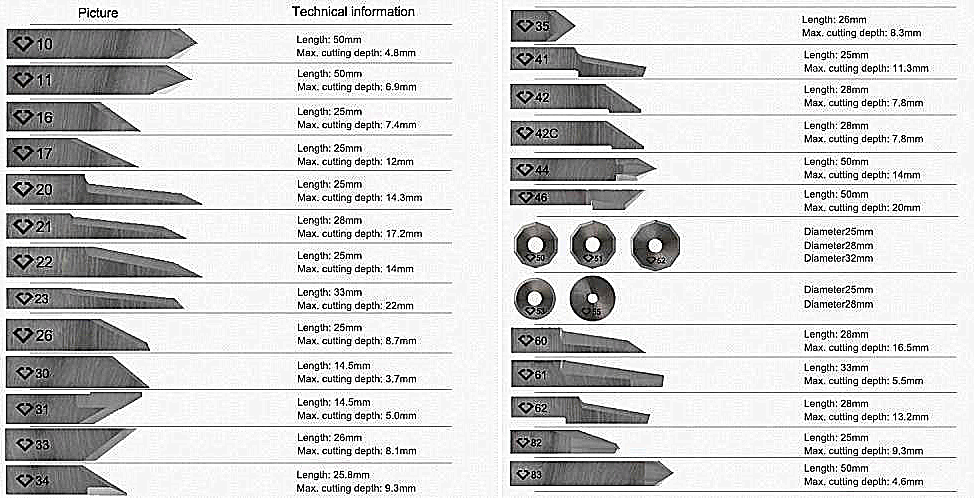

- Round-Stock Blades: Compatible with tools like C2, C2P, KCT, KCM-S. Examples include Z1, Z2, Z3, Z4, Z5, Z7.

- Flat-Stock Blades:Compatible with tools like UCT, SCT, insert sleeve 40. Examples include Z6, Z10, Z11, Z44, Z46, Z101, Z102, Z103, Z83.

- V-Cut Blades: Used with the VCT tool for creating angled cuts. Examples include Z70, Z71, Z701, Z73.

- Mat-Cutting Blades: Used with PPT tools for cutting materials like mats. Examples include Z30, Z33, Z34, Z35.

If you're uncertain about the appropriate tool and blade combination for your specific application, consider consulting with Shenzhen Oyea Machinery Co., Ltd. They can provide personalized recommendations based on your production needs.

By carefully selecting the appropriate tools and blades, you can optimize your Zund cutting system's performance, ensuring precision and efficiency in your production processes.

PREV : Summa Aristo Gerber Esko Roland Zund Knives And CNC Knife Blades Are Widely Sold And Distributed NEXT : Atom Kimla Polska Grupa Cnc Seron Tungsten Steel Blade Compatibility Replacement Applicable