.Material Considerations

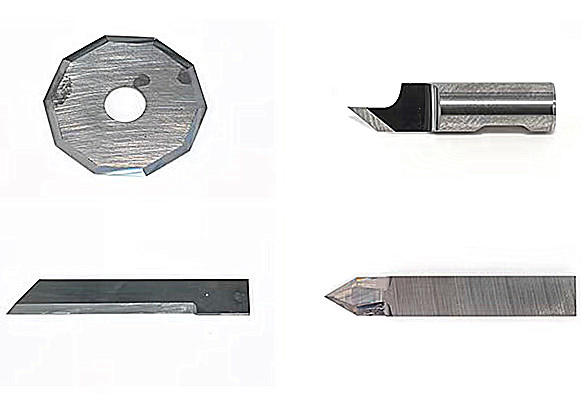

Different materials require specific blades for optimal performance:

- Paper, Cardboard, Folding Carton: Standard drag knives or oscillating knives.

- Corrugated Board: Corrugated knife (single- or double-edged).

- Foam Board & Soft Materials: Oscillating knife for clean cuts.

- Acrylic & Plastics: Milling bit (high-speed router bit).

- Textiles & Vinyl: Kiss-cut knife or rotary knife.

- Wood & MDF: Router bits (high-power spindle).

2. Tungsten Carbide Blade Benefits

Tungsten carbide blades are ideal for tougher materials due to their:

- Durability: Longer lifespan compared to steel blades.

-Heat Resistance: Excellent performance at high temperatures.

- Versatilit: Suitable for various materials and applications.

3. Blade Selection Tips

- Blade Angle: Choose the right angle based on material density and desired cut precision. For example, steeper angles (30° to 35°) are better for denser materials.

- Blade Thickness: Thicker blades (e.g., 1.5mm) offer more rigidity, essential for cutting harder materials.

- Cobalt Content: Typically 6-12% cobalt enhances toughness and reduces brittleness in tungsten carbide blades.

4. Compatibility with Esko Kongsberg Models

Ensure the blade is compatible with your specific Kongsberg model (e.g., Kongsberg X, C, XP). Some machines may require specific tool adaptors.

5. Applications of Tungsten Carbide Blades

These blades are suitable for cutting a variety of materials, including:

- Cast aluminum

- Fiberglass

- Graphite

- Titanium

- Superalloys.

By considering these factors, you can select the most appropriate tungsten carbide blade for your Esko Kongsberg flatbed cutter system to achieve optimal cutting performance and longevity.

Shenzhen Oyea Global sales: ensuring availability across Europe, the USA, the Middle East, and Asia with efficient shipping and customer service.Sold To Germany, France, The United Kingdom, Poland, The United States, Russia, Vietnam, Thailand, Indonesia, Singapore, The Netherlands, Switzerland, South Korea, Japan, Turkey, The Philippines, Hong Kong, Taiwan, Italy, Spain, Hungary, The Czech Republic And Other Countries Or Regions

PREV : Summa Aristo Gerber Esko Roland Zund Knives And CNC Knife Blades Are Widely Sold And Distributed NEXT : Atom Kimla Polska Grupa Cnc Seron Tungsten Steel Blade Compatibility Replacement Applicable