General Steps to Replace the Blade on an Oscillating Knife

1. Power Off or Pause the Machine

- Safety first: Turn off the machine or put it in a safe/manual mode.

- Ensure the cutting head is in an accessible location.

2. Locate the Oscillating Tool Module

- Identify the specific module/tool head (e.g., EOT on Zund, PowerHead on Esko, etc.).

- The blade is usually held in a tool holder or chuck.

3. Loosen the Blade Clamp or Screw

- Use the correct hex key (Allen wrench) or screwdriver.

- Loosen the set screw or clamp that holds the blade in place.

- Carefully pull the old blade straight out — avoid bending or twisting.

4. Insert the New Blade

- Hold the new blade with care (preferably with gloves).

- Insert the blade into the holder to the correct depth — some systems have depth stops, others need manual adjustment.

- Make sure it's aligned properly and not off-center.

5. Tighten the Clamp or Screw

- Firmly tighten the clamp/screw, but don’t overtighten — this can crack the blade or strip the threads.

6. Check Oscillation

- Some systems allow you to test the oscillating motion to make sure the blade is secure.

- Gently move the tool manually or use a test mode if available.

7. Reset Blade Parameters (if needed)

- In your cutting software or controller interface (e.g., Zund Cut Center, Esko i-Cut, etc.), reset or confirm:

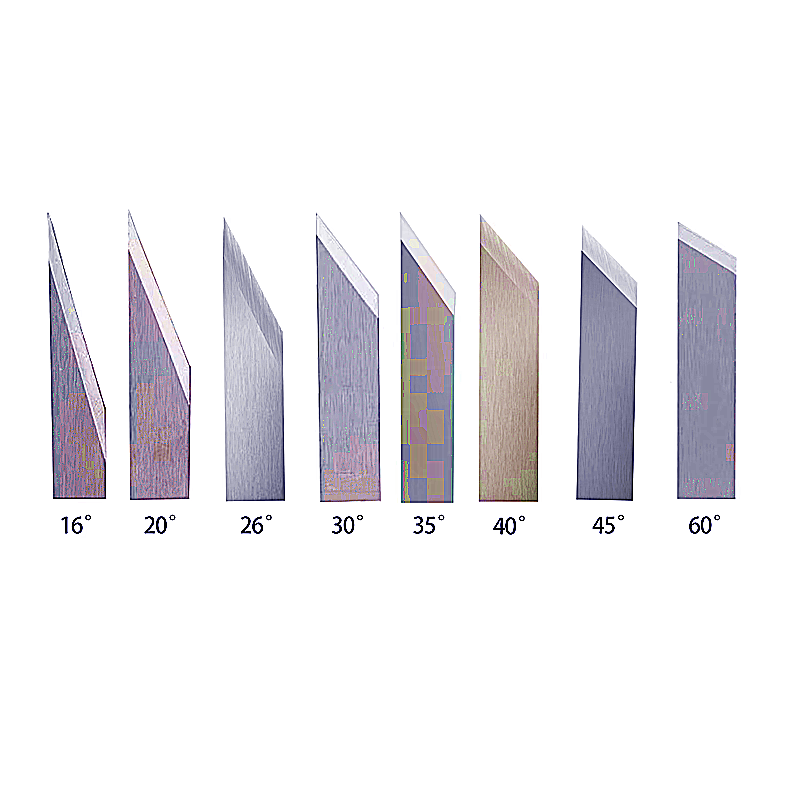

- Blade type

- Cutting depth

- Pressure/speed settings

- This step is crucial if your system auto-detects blade types or uses barcode scanning for tool recognition.

8. Run a Test Cut

- Always do a test cut on scrap material to make sure everything is functioning correctly.

Notes by Brand:

- Zund(e.g., EOT/2, POT): Use the tool-specific blade holder. Some tools have quick-release mechanisms. The blade depth can be adjusted via a dial or screw.

- Esko Kongsberg: Uses blade inserts into cartridges, often color-coded. The machine might auto-recognize the tool once reinserted.

- Summa F Series: Blade is inserted into the tangential or oscillating module with a locking ring or set screw.

- iEcho: Similar to Zund/Summa. Blade installation usually involves loosening a small hex screw.

Shenzhen Oyea Global sales: ensuring availability across Europe, the USA, the Middle East, and Asia with efficient shipping and customer service.Sold To Germany, France, The United Kingdom, Poland, The United States, Russia, Vietnam, Thailand, Indonesia, Singapore, The Netherlands, Switzerland, South Korea, Japan, Turkey, The Philippines, Hong Kong, Taiwan, Italy, Spain, Hungary, The Czech Republic And Other Countries Or Regions

PREV : Esko Kongsberg Aristo Summa EcoCam Stepcraft MultiCam Oscillating Tangential Knife OTK NEXT : Esko Kongsberg Bld-Sf420 Summa 500-9811 Zund Z20 Colex T00420 Iecho E20 Cnc Oscillating Knife Blade