OEM (Original Equipment Manufacturer)

What it means: You provide the design, and the manufacturer produces it.

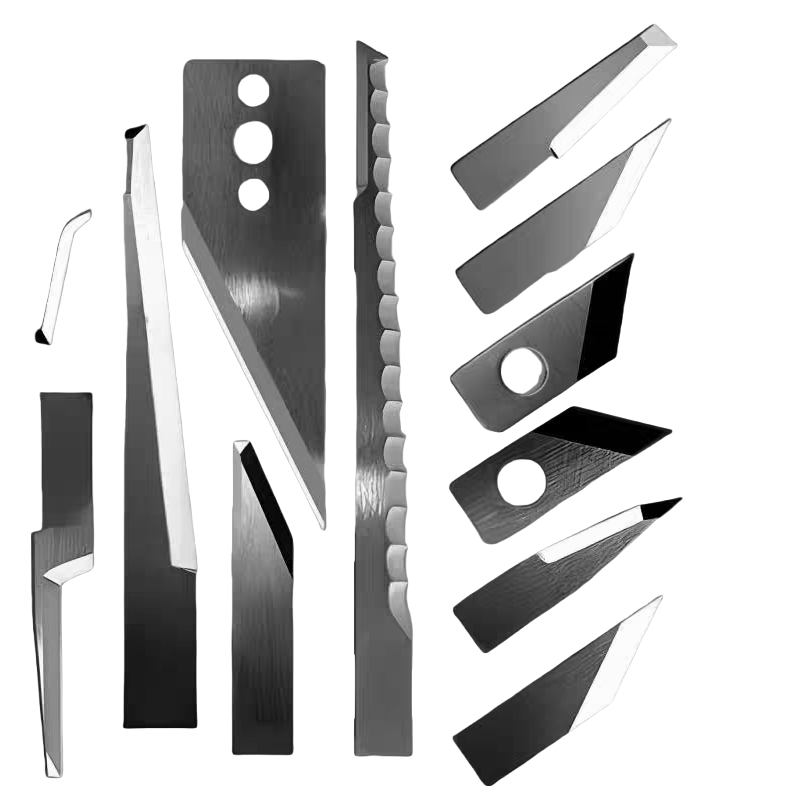

Blade example: You design the tungsten steel blade – its shape, hardness, edge geometry, etc. – and the OEM factory just makes it to your exact specs.

Who uses this: Companies with their own R&D or product engineering teams.

Pros:

Full control over design and quality.

You own the intellectual property (IP).

Ideal for unique or specialized blade applications.

Cons:

Longer lead time (design, prototyping).

Higher costs initially due to customization.

ODM (Original Design Manufacturer)

What it means: The manufacturer already has a blade design; you just rebrand it.

Blade example: The factory offers pre-designed tungsten steel blades that you can label with your brand.

Who uses this: Companies focused on speed to market or cost efficiency.

Pros:

Faster and cheaper.

Great for standard applications.

Cons:

Limited design flexibility.

You don’t own the design or IP.

Which One is Better?

It depends on your needs:

Purpose Go With

Custom design & premium quality OEM

Fast production & lower cost ODM

If you're selling a high-end blade for industrial use, OEM is likely the way to go. If you're starting a private label brand and want quick inventory, ODM is probably better.

Shenzhen Oyea Global sales: ensuring availability across Europe, the USA, the Middle East, and Asia with efficient shipping and customer service.Sold To Germany, France, The United Kingdom, Poland, The United States, Russia, Vietnam, Thailand, Indonesia, Singapore, The Netherlands, Switzerland, South Korea, Japan, Turkey, The Philippines, Hong Kong, Taiwan, Italy, Spain, Hungary, The Czech Republic And Other Countries Or Regions

PREV : Summa Aristo Gerber Esko Roland Zund Knives And CNC Knife Blades Are Widely Sold And Distributed NEXT : Atom Kimla Polska Grupa Cnc Seron Tungsten Steel Blade Compatibility Replacement Applicable