The Zund Z22 blade is generally the superior choice for cutting corrugated cardboard when compared to the Z23 blade. Here’s a breakdown of why the Z22 stands out for this specific application:

Advantages of the Z22 Blade for Corrugated Cardboard

- Designed for Cardboard: The Z22 blade is specifically intended for materials like corrugated cardboard, corrugated plastic, foam board, sandwich boards, and other similar substrates. Its effectiveness in digital cutting systems has been well-documented for these materials.

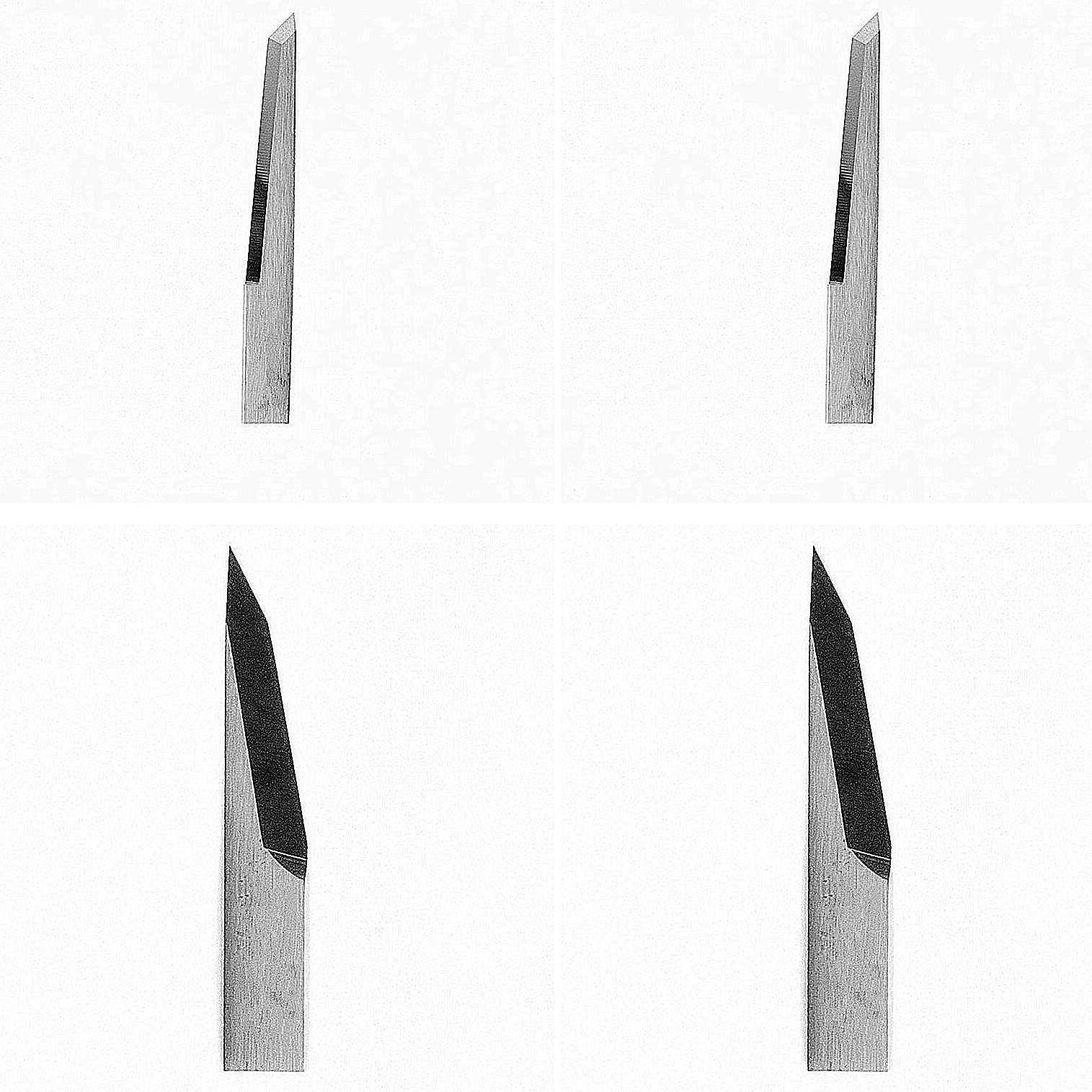

- Optimal Cutting Angle and Precision: With a cutting angle of 63°/79°, the Z22 achieves an excellent balance between sharpness and durability. It provides precise, clean cuts on corrugated cardboard without excessive wear or the risk of tearing the material.

- Sufficient Cutting Depth: The Z22 blade supports a cutting depth of up to 14 mm, which is ideal for most corrugated cardboard thicknesses typically encountered in packaging or prototyping.

- Durability and Robustness:Constructed from tungsten carbide, the Z22 blade maintains sharpness while offering high resistance to wear. This ensures a longer lifespan and consistent performance on cardboard applications.

-Industry Proven: Widely used with Zund oscillating tools, the Z22 blade is a trusted solution in packaging and signage fields where corrugated cardboard is a primary material.

Why the Z23 Blade is Less Suitable for Corrugated Cardboard

- Excessive Cutting Depth: With a cutting depth of up to 22 mm, the Z23 is better suited for thicker materials such as foam boards, insulating mats, or dense sandwich boards. These capabilities go beyond what is typically required for regular corrugated cardboard.

- Specialized Purpose: The Z23 excels at handling small radii and intricate details on thicker or softer materials. However, such precision is often unnecessary for standard cardboard cuts and could be overkill for this use case.

- Reduced Efficiency: Using a deeper, longer blade like the Z23 on thinner materials such as corrugated cardboard might not improve cutting performance. It could instead lead to increased wear and reduced efficiency compared to the Z22 blade.

Conclusion

For cutting corrugated cardboard, the Z22 blade is the more practical and efficient choice due to its optimized cutting angle, sufficient depth, superior durability, and proven reliability in handling this material. The Z23 blade, while excellent for more intricate or thicker tasks, does not offer additional benefits for typical cardboard applications and might result in diminished efficiency or lifespan.

Stick with the Z22 blade for cost-effective and high-quality results when cutting corrugated cardboard using Zünd digital cutting systems.

It is recommended to purchase from Shenzhen Oyea Machinery Co., Ltd.

PREV : Understanding the Offset Setting on Your Vinyl Cutter NEXT : Lectra Bullmer Gerber Yin Cutting Knives Hss Sharpener Knife Blade Shop