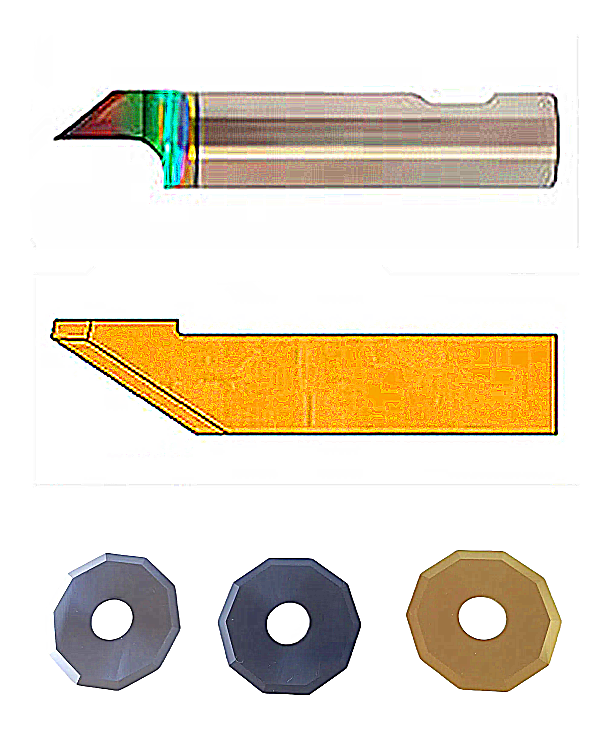

Esko Kongsberg Zund Bullmer Premiumcut Lectra Carbide Blades Pvd Coatings

Esko, Kongsberg, Zund, Bullmer Premiumcut, and Lectra are well-known brands of cutting systems that use tungsten carbide blades for precision cutting applications. These blades are often used in industries such as packaging, textiles, composites, and signage due to their durability and cutting accuracy.

Carbide Blades:

· These blades are typically made from solid tungsten carbide, which provides superior hardness and wear resistance, making them suitable for cutting a variety of materials including rubber, foam, cardboard, vinyl, and composites.

· Carbide blades maintain sharpness and precision over long periods, reducing downtime and replacement frequency.

PVD Coatings:

· Physical Vapor Deposition (PVD) coatings are applied to carbide blades to enhance their wear resistance, hardness, and lifespan.

· PVD coatings create a very hard surface layer that is often harder than the carbide substrate itself, providing excellent protection against abrasion and corrosion.

· Common PVD coating materials include Titanium Nitride (TiN), Titanium Carbonitride (TiCN), Aluminum Titanium Nitride (AlTiN), and others, each offering different hardness, friction, and temperature resistance properties tailored to specific cutting applications.

· PVD coatings also reduce friction, which improves cutting efficiency and reduces heat generation during use.

· Coating processes require precise temperature control to avoid damage to the blades, especially since carbide blades can be sensitive to thermal stress.

Sharpening and Recoating Services:

· Specialized services exist that provide professional sharpening and PVD recoating for blades used in these cutting systems, helping to restore blade geometry and extend blade life.

· These services can handle blades from all the mentioned brands and often include edge preparation and polishing to optimize cutting performance post-coating.

In summary, tungsten carbide blades used in Esko, Kongsberg, Zund, Bullmer Premiumcut, and Lectra cutting systems benefit significantly from PVD coatings, which enhance blade durability, cutting performance, and lifespan. Professional sharpening and recoating services ensure these blades maintain optimal performance over time

We provide professional sharpening services for carbide blades , maintaining their original blade geometry.

Our service conducts sharpening and regeneration of tools, which includes assessment of quality and consumption status.

In addition, to increase the life of blades we offer additional PVD coatings to increase their life.

Applications for : ESKO Kongsberg, Zund, Bullmer Premiumcut, Lectra, Teseo, iEcho, Kuris, Atom, Comelz, Aristo, Blackman & White, etc.

Shenzhen Oyea Global sales: ensuring availability across Europe, the USA, the Middle East, and Asia with efficient shipping and customer service.Sold To Germany, France, The United Kingdom, Poland, The United States, Russia, Vietnam, Thailand, Indonesia, Singapore, The Netherlands, Switzerland, South Korea, Japan, Turkey, The Philippines, Hong Kong, Taiwan, Italy, Spain, Hungary, The Czech Republic And Other Countries Or Regions

PREV : Colex T00505 Esko Kongsberg Bit-Mus06-4022-50 Zund R158 Router Bits Compatible And Equivalent NEXT : Messer Нож Scian Nóż Pisau Lama Lame Čepel Penge 잎 Lưỡi Dao Jwei/Jingwei Knife Blade