When selecting cutting knife blades and knives for Comelz digital cutters, especially for flatbed cutting systems, it’s essential to focus on blades that ensure precision, durability, and compatibility with the specific Comelz models. Comelz blades are well-regarded for their tungsten carbide construction, which provides excellent wear resistance and cutting performance across a variety of materials like leather, textiles, cardboard, and composites.

Here are expert recommendations for Comelz cutting knife blades and knives tailored to Comelz digital cutters and flatbed cutting systems:

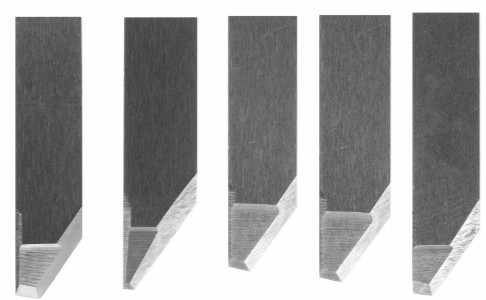

1.Comelz Tungsten Carbide Oscillating Knife Blades (e.g., HZ3X.L, HZ5K, HZ2P series)

Why choose: These blades are specifically designed for Comelz automated cutting machines, ensuring perfect fit and optimal performance. Tungsten carbide construction offers extreme durability and sharpness retention, enabling clean, precise cuts even on tough materials like leather, carbon fiber, and rubber.

Differentiators: The oscillating mechanism combined with tungsten carbide tips allows for smooth cutting action with minimal wear, reducing downtime for blade changes. Different models (HZ3X, HZ5K, HZ2P) cater to various cutting depths and material thicknesses, providing versatility.

Advantages: Long-lasting sharpness, compatibility with Comelz's oscillating electric tools, and ability to handle a wide range of materials. This reduces blade replacement frequency and improves cutting consistency.

Drawbacks: These are specialized blades, so they may come at a premium compared to generic blades. Also, selecting the correct blade model is crucial to match your cutter’s specifications.

Personalization: Ideal for users operating Comelz flatbed cutters in industries like garment manufacturing, automotive upholstery, and technical textiles, where precision and blade longevity are critical.

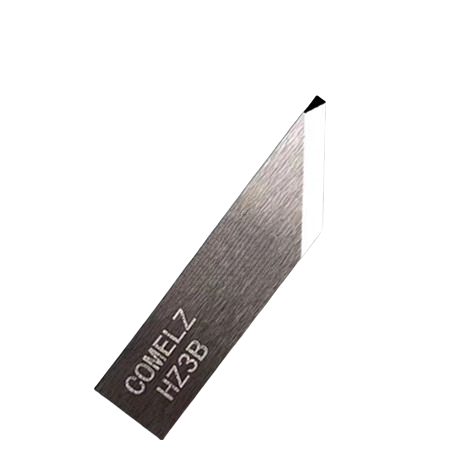

2.OEM Tungsten Carbide COMELZ Blades (e.g., HZ3B, HZ2R, HZ4N)

Why choose: OEM blades ensure original equipment manufacturer quality, guaranteeing precise dimensions and material standards. These blades maintain the high cutting performance expected from Comelz cutters.

Differentiators: OEM blades often come with strict quality control and are designed to maximize the life of your cutting machine’s components. They typically feature optimized blade geometry for clean cuts and reduced wear on the machine.

Advantages: Reliable performance, reduced risk of machine damage, and consistent cutting quality. OEM blades are often backed by manufacturer support.

Drawbacks: OEM blades might be less flexible in terms of pricing or availability compared to aftermarket options.

Personalization: Best for users who prioritize machine warranty compliance and consistent cutting results without experimenting with third-party blades.

3.Aftermarket Tungsten Carbide Blades Compatible with Comelz (e.g., from suppliers like Shenzhen Oyea Machinery Co., Ltd.)

Why choose: These blades offer a cost-effective alternative to OEM products while maintaining tungsten carbide toughness. They often cover a wide range of Comelz blade models and sizes.

Differentiators: They can provide excellent value and availability, especially for bulk purchases or when OEM blades are harder to source. Some aftermarket blades also come with specialized coatings or enhanced sharpness for niche applications.

Advantages: More affordable, widely available, and sometimes customized for specific cutting needs.

Drawbacks: Quality and fit can vary between suppliers, so it’s important to verify compatibility and performance through reviews or samples. Using non-OEM blades might risk slight inconsistencies in cutting or machine wear.

Personalization: Suitable for budget-conscious operators or those with experience tuning their machines to accommodate different blade brands.

4.Comelz Cutting System Accessories (Cutting Underlays and Pads)

Why choose: While not blades, cutting underlays like the SCplus conveyor belt and cutting pads complement blade performance by providing a stable cutting surface and protecting the blade edges.

Differentiators: Using recommended cutting underlays extends blade life and improves cut quality by preventing blade damage from hard surfaces.

Advantages: Enhances overall cutting system efficiency and reduces perational costs by preserving blade sharpness.

Drawbacks: Requires additional maintenance and replacement cycles for the underlays themselves.

Personalization: Essential for users aiming for high-precision cuts and longer blade life in high-volume production environments.

Shenzhen Oyea Global sales: ensuring availability across Europe, the USA, the Middle East, and Asia with efficient shipping and customer service.Sold To Germany, France, The United Kingdom, Poland, The United States, Russia, Vietnam, Thailand, Indonesia, Singapore, The Netherlands, Switzerland, South Korea, Japan, Turkey, The Philippines, Hong Kong, Taiwan, Italy, Spain, Hungary, The Czech Republic And Other Countries Or Regions

Summary: For the best results with Comelz digital cutters and flatbed systems, prioritize tungsten carbide oscillating knife blades designed specifically for Comelz models (such as the HZ3X.L and HZ5K series). OEM blades guarantee optimal fit and performance, while reputable aftermarket options can offer cost.

PREV : Iecho Tools Compatible With Iecho Automatic Cutting Machines NEXT : What Are The Differences Between Zund Z6, Z10, Z11, Z44, Z46, Z101, Z102, Z103, And Z83 Blades