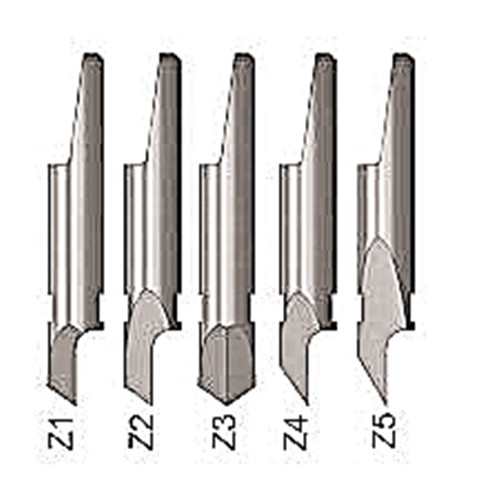

How to choose and use ZUND Z1 Z2 Z3 Z4 Z5 W6 Z6 Z7 tungsten steel blades

To choose and use Zund tungsten steel blades (Z1, Z2, Z3, Z4, Z5, W6, Z6, Z7), consider the following expert guidelines based on blade type, material, and cutting requirements:

Choosing Zund Tungsten Steel Blades

· Blade Types and Applications:

Z1, Z2, Z3, Z4, Z5, Z7: These are round-stock drag blades suitable for cutting materials such as self-adhesive vinyls, reflective vinyls, masking films, cardstock, paper, thin folding cartons, banners, and pattern materials.

W6: Also a round shaft drag knife compatible with the same pressure mode and working area restrictions as Z1-Z5 blades.

Z6: Not explicitly detailed in the search results, but likely similar in use to other round-stock blades.

· Material Compatibility:

Use round-stock blades (Z1-Z5, Z7) for thin to medium materials like vinyl, paper, and thin cartons.

For heavier materials or specialized cutting, refer to oscillating blades or other blade types (not covered specifically in your query but detailed in Zund catalogs).

· Blade Material and Durability:

All these blades are made of tungsten carbide, offering excellent durability and longer life expectancy compared to high-speed steel blades.

· Cutting Depth and Pressure:

The pressure mode for these drag knives ranges from 30 to 1500 grams, with a blade weight around 1.7 kg.

The working area restrictions for these blades are approximately 5.5 mm in X and 6 mm in Y directions, which affects cutting precision.

Using Zund Tungsten Steel Blades

· Installation:

Use the correct blade holder compatible with the blade type (e.g., blade holder type 1 for drag blades like Z11; round shaft blades use their specific holders)

· Cutting Parameters:

Adjust cutting pressure within the recommended range (30-1500 g) depending on material thickness and type

Set the cutting depth based on the material thickness plus a small additional depth to ensure clean cuts without damaging the cutting surface.

· Blade Selection Tips:

Choose blades with smaller overcut values for jobs requiring high precision to minimize distortion of cutting contours.

For materials with curves and long straight cuts, blades with narrower cutting angles can be used to increase speed but may increase overcut.

· Maintenance:

Regularly inspect blades for wear and replace when cutting quality decreases.

Tungsten carbide blades have longer life but still require periodic replacement depending on usage intensity and material abrasiveness.

Summary Table of Z1 to Z5 Blades (Typical Use)

|

Blade |

Type |

Suitable Materials |

Notes |

|

Round-stock drag |

Standard self-adhesive vinyls |

General purpose |

|

|

Round-stock drag |

Reflective vinyls, masking film |

Stable, long-life double-edged |

|

|

Round-stock drag |

Small lettering on vinyls |

Precise cutting |

|

|

Round-stock drag |

Paper, thin cartons, banners |

Versatile for thin materials |

|

|

Round-stock drag |

Similar to Z4 |

General cutting |

For detailed specifications and exact cutting depths, consult the Zund product catalogs and blade datasheets.

![]()

This guidance ensures optimal blade selection and usage for your Zund cutting system to achieve precise, efficient, and durable cutting performance.

Shenzhen Oyea Global sales: ensuring availability across Europe, the USA, the Middle East, and Asia with efficient shipping and customer service.Sold To Germany, France, The United Kingdom, Poland, The United States, Russia, Vietnam, Thailand, Indonesia, Singapore, The Netherlands, Switzerland, South Korea, Japan, Turkey, The Philippines, Hong Kong, Taiwan, Italy, Spain, Hungary, The Czech Republic And Other Countries Or Regions

PREV : Colex T00505 Esko Kongsberg Bit-Mus06-4022-50 Zund R158 Router Bits Compatible And Equivalent NEXT : Messer Нож Scian Nóż Pisau Lama Lame Čepel Penge 잎 Lưỡi Dao Jwei/Jingwei Knife Blade