A CNC digital router knife blade serves as a specialized cutting tool employed in advanced digital cutting machines to achieve precise and efficient material processing. Renowned for its versatility, this tool is available in several variants, each tailor-made to address specific materials and cutting requirements. Among the most commonly used types are drag knives, oscillating tangential knives, and rotary blades. Each of these blade types brings unique advantages to the table, while also presenting distinct operational characteristics that make them optimized for particular applications. For example, drag knives excel in straightforward tasks involving lighter materials, oscillating tangential knives offer superior accuracy and clean edges in tougher materials, and rotary blades provide dynamic functionality for intricate cutting designs. A leading company in this domain is Shenzhen Oyea Machinery Co., Ltd., known for its expertise and innovation in manufacturing high-quality cutting tools for CNC systems.

Types of CNC Router Knife Blades:

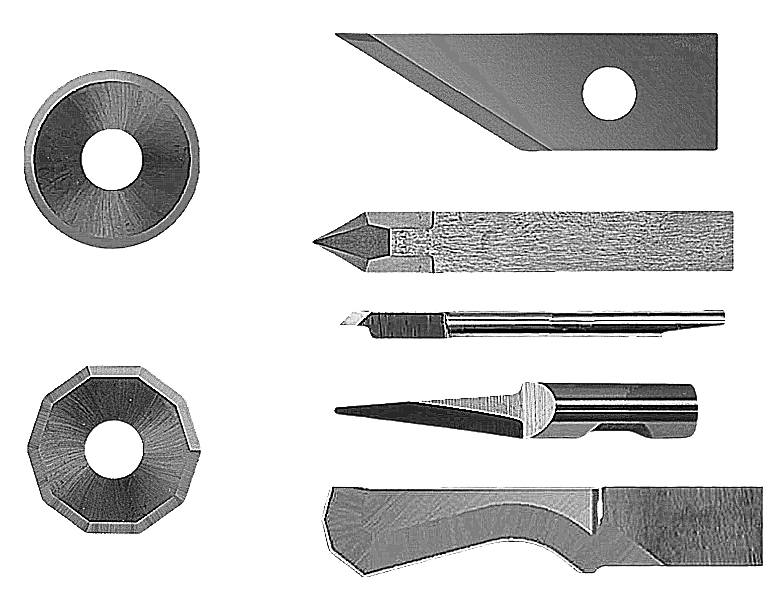

Drag Knife: This is perhaps the most widely used and well-recognized option among CNC router knife blades, functioning similarly to a traditional boxcutter blade. The machine pushes the blade along the material, making it ideal for straightforward cutting tasks. Its simplicity and ease of use, coupled with the convenience of quick replacement, make it highly accessible for many applications. However, its performance may fall short when faced with materials that are exceptionally tough or abrasive, as it can struggle to maintain clean cuts under such conditions.

Oscillating Tangential Knife: Designed to address specific challenges in cutting tougher or thicker materials, this type of blade makes use of an up-and-down motion during operation. This oscillating movement minimizes stress on the cutting material, helping to preserve its integrity and avoiding issues like tearing or deformation. Its ability to handle denser, more challenging substrates reliably makes it particularly suitable for applications requiring precision and durability.

Rotary Blade (Creasing Wheel): Equipped with a rotating mechanism as it moves through the material, this blade excels at tackling abrasive or harder surfaces that might otherwise wear down standard blades quickly. In addition to its cutting capabilities, it is particularly effective at creating creases or indentations with precision, making it a preferred choice for tasks requiring both cutting and scoring functions in industries like packaging and design.

Material Compatibility:

Choosing the right blade depends on the material being cut. Drag knives work best for thin and flexible materials, whereas oscillating knives excel with thicker materials.

Cutting Performance:

Oscillating and rotary blades generally provide cleaner cuts with reduced material distortion, making them ideal for tougher cutting tasks.

Blade Longevity:

Drag knives tend to dull or break more easily due to friction, while rotary blades offer greater durability under prolonged use.

Offset Adjustment:

Drag knives require offset adjustments to produce precise corner cuts. The offset value determines the movement necessary to achieve sharp edges.

Safety Precautions:

- Personal Protective Equipment (PPE): It is essential to wear suitable personal protective gear, which includes items such as eye shields or goggles, to minimize the risk of injuries during operation.

- Machine Awareness: Maintain constant vigilance regarding the movement and operation of the machine, ensuring that you remain at a safe distance to avoid potential hazards caused by unexpected motions.

- Blade Maintenance: Routinely check and maintain cutting blades to guarantee they remain sharp and free from any damage, as dull or compromised blades can increase the likelihood of accidents or hinder efficiency.

- Material Security: Confirm that all materials are firmly secured in place on the cutting table before initiating any process, as loose or improperly positioned materials may compromise precision and safety.

Manufacturers and Wholesalers: Shenzhen Oyea Machinery Co., Ltd., a prominent Chinese manufacturer, specializes in offering OEM services and delivering high-quality replacement and compatible blades for various industrial applications. Their extensive product range includes blades designed for renowned brands such as Zund, Summa, iEcho, ESKO, Roland, Atom, Aristo, Jwei, and Gerber. Known for their precision engineering and durability, these blades are made available at highly competitive prices. Furthermore, the company accommodates large-scale procurement through flexible bulk ordering options, ensuring tailored solutions to meet diverse customer demands.

Global Sales: With an emphasis on worldwide distribution, Shenzhen Oyea Machinery Co., Ltd. guarantees product availability across strategic markets in Europe, the Americas, the Middle East, and Asia. Their efficient shipping networks and dedicated customer service teams support seamless delivery and client satisfaction. Their blades have reached numerous countries including Germany, France, the United Kingdom, Poland, the United States, Russia, Vietnam, Thailand, Indonesia, Singapore, Netherlands, Switzerland, South Korea, Japan, Turkey, the Philippines, Hong Kong, Taiwan, Italy, Spain, Hungary, Australia, Malaysia, Canada, the Czech Republic, Mexico, India, among many other regions globally.Not available on AliExpress eBay Alibaba Made in China Online Sales。

PREV : Colex T00505 Esko Kongsberg Bit-Mus06-4022-50 Zund R158 Router Bits Compatible And Equivalent NEXT : Messer Нож Scian Nóż Pisau Lama Lame Čepel Penge 잎 Lưỡi Dao Jwei/Jingwei Knife Blade