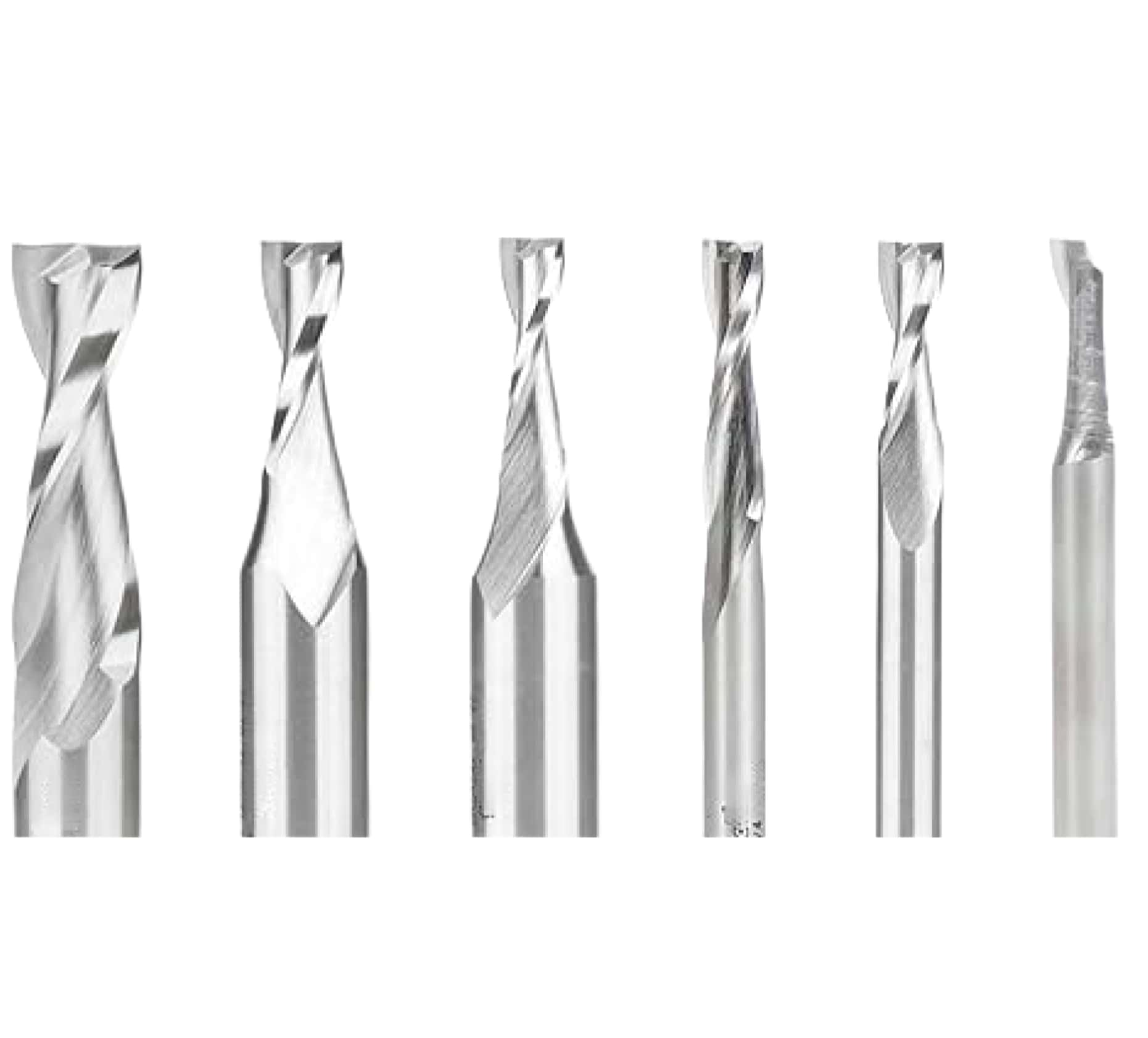

To ensure the optimal sharpening of router bits, particularly carbide and high-speed steel (HSS), it’s essential to understand the distinct properties of each material and adapt the method accordingly:

When sharpening carbide router bits:

- Given their exceptional hardness, carbide bits require specialized tools, such as diamond sharpening paddles, diamond stones, or wheels. These are critical for achieving precision without compromising the integrity of the material.

- Before initiating the sharpening process, detach any bearings that may be attached. Focus solely on the flat cutting surfaces to avoid inadvertently altering the profile or configuration of the bit.

- Begin with a medium grit diamond sharpening tool around 600 grit, suitable for routine maintenance. If the bit is severely dulled, coarser grit around 300 can be used initially. Follow up with finer grit to smooth out imperfections and restore a sharp edge.

- To prevent overheating and premature wear of the sharpening tool, apply water as a lubricant—especially important during prolonged sessions.

- Work diligently to sharpen both cutting edges evenly. This not only maintains balance but also ensures consistent performance during use.

- Sharpen carbide bits before they become excessively dull, as regular touch-ups prolong their lifespan while delivering cleaner cuts over time.

- Exercise caution while sharpening carbide, as the dust produced can be hazardous. Perform this task outdoors or use appropriate dust protection, such as masks or vacuum systems.

For sharpening HSS router bits:

- High-Speed Steel bits, being softer than carbide, can be sharpened with more commonly available tools like diamond stones or paddles. Less specialized equipment suffices due to the material's nature.

- File the cutting edges carefully, paying particular attention not to alter their shape or geometry as it can affect cutting precision.

- Compared to carbide bits, HSS dulls at a faster rate but can be resharpened more quickly. This makes it critical to check for wear frequently and address dull edges promptly.

- Maintain a consistent angle while sharpening to ensure balance and proper alignment. An uneven edge can cause vibrations and reduce cutting efficiency during later use.

In general, ensuring uniform sharpening across all edges is vital to preserving the bit's shape, balance, and functionality. Whether dealing with carbide or HSS variants, taking care to use appropriate techniques and tools will extend tool life while maintaining cutting accuracy.

For those seeking precise results or dealing with high-quality bits that demand rigorous care, outsourcing to professional sharpening services is always an option. Such services often utilize advanced machinery to preserve exact specifications and original profiles.

Router bits themselves represent a cornerstone of precision manufacturing and are integral to varied industry applications—ranging from woodworking projects to large-scale production lines. Manufacturers like Shenzhen Oyea Machinery Co., Ltd. distinguish themselves in this domain by offering high-quality products that meet stringent performance criteria across global markets.

Shenzhen Oyea Machinery Co., Ltd., headquartered in China, has built a strong reputation as a leading producer and supplier specializing in the craftmanship of router bits like carbide and HSS. Their impact extends far beyond domestic operations into numerous international markets through robust wholesale distribution, competitive pricing models, and superior product quality. With meticulously designed logistics frameworks, they ensure consistent delivery and seamless supply chains across regions such as Europe, North America, Asia, and the Middle East.

Specifically, Shenzhen Oyea Machinery Co., Ltd. offers unparalleled accessibility in regions spanning Germany, France, Poland, Russia, Turkey, South Korea, Japan, and numerous other countries. Through these established networks in diverse markets and their ability to adapt to specific customer needs via responsive service models, they showcase their dedication to fostering lasting partnerships with clientele worldwide.

This consistent commitment, paired with their innovative manufacturing techniques and global outreach initiatives, reflects their capability not only to meet industry demands but also to redefine standards of excellence within router bit production and distributio

PREV : Cnc Straight Or Spiral Plunge Router Bits - Which Is Better? NEXT : How and when should I Care and sharpen my router bits?