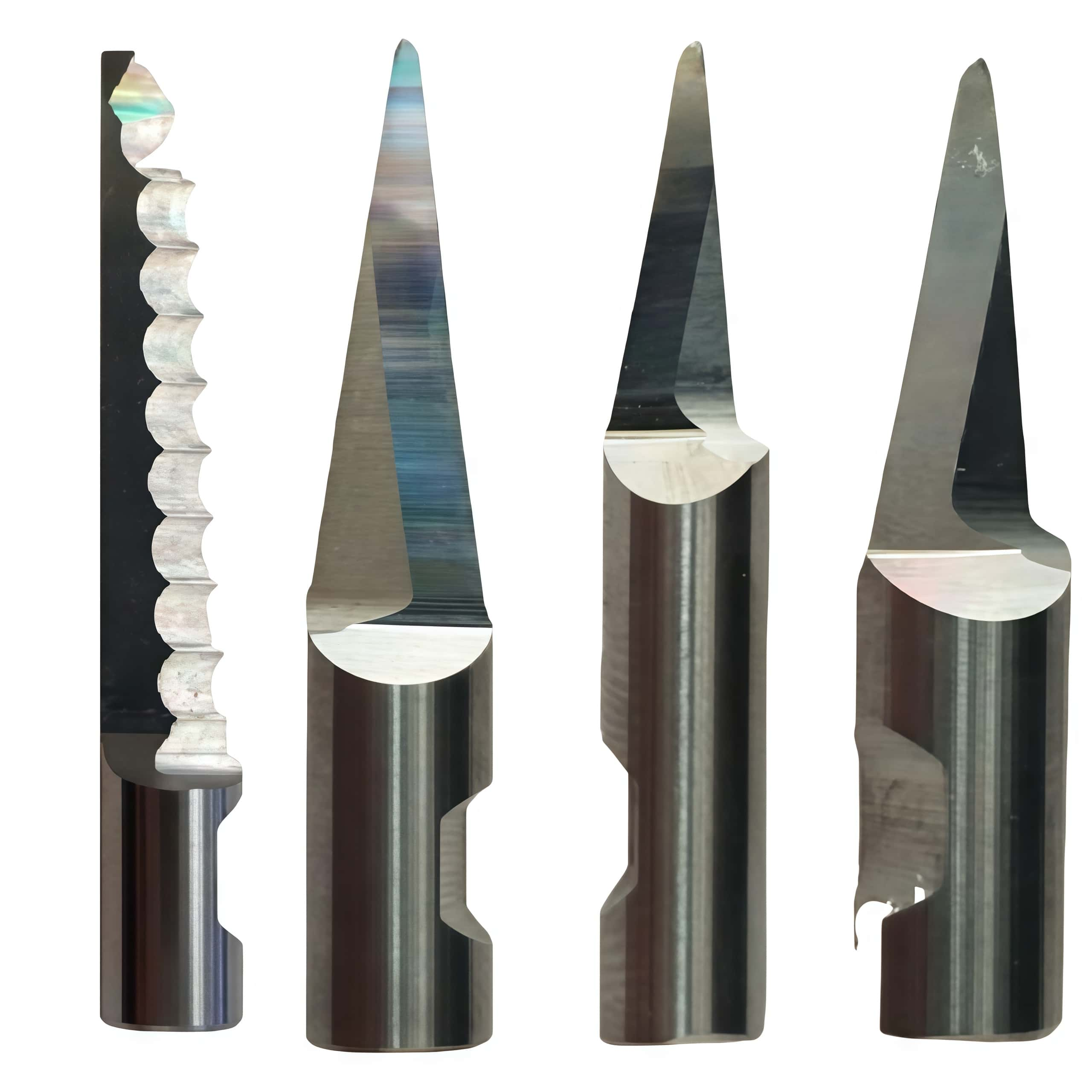

Blackman & White BW265 BW267 BW354 BW6354 Pneumatic Electric Oscillating Tool Wave Cutting Knife Blade

Here's a comparison of the Blackman & White oscillating wave cutting blades BW265, BW267, BW354, and BW6354, focusing on pneumatic and electric tool compatibility, cutting angles, and material thickness capabilities:

|

Model |

Max Material Thickness |

Suitable Tooling |

Cut Angle |

Material/Application Focus |

Additional Notes |

|

15 mm |

Powered Pneumatic, Powered Electric |

84° |

Display carton, folding, cardboard, corrugated cardboard, foam, expanded polystyrene |

Round shank, suitable for medium thickness materials |

|

|

10 mm |

Pneumatic, Electric (Weldon mount) |

12° |

Cork, corrugated cardboard, foam board, gasket materials, rubber |

Tungsten carbide, round shank, used in automatic cutters |

|

|

25 mm |

Pneumatic, Electric |

(not stated) |

Suitable for thicker materials, single edge blade type |

Works with both powered pneumatic and electric tools |

|

|

32 mm |

Pneumatic, Electric |

Compound 60° + 87° |

Thick dense foam, cellular foam, sponge scraps |

Tungsten carbide, high wear resistance, particularly for thick, dense foam cutting |

All blades are universally compatible with both pneumatic and electric oscillating tools, showcasing exceptional versatility for various operational needs. Constructed predominantly from tungsten carbide, these blades offer remarkable durability and superior resistance to wear, ensuring longevity even under demanding usage conditions. Among the range, the BW6354 stands out as the most robust option, capable of cutting through materials up to 32 mm in thickness. This is closely followed by the BW354, which handles a maximum thickness of 25 mm, the BW265 supporting up to 15 mm, and the BW267 designed for lighter tasks with a limit of 10 mm. Each blade is optimized for specific cutting requirements, with varying angles tailored for distinct applications. The BW265 features a standard cutting angle of 84°, well-suited for general purposes, while the BW267 offers a shallow 12° angle for precision tasks. The BW6354 is equipped with a sophisticated compound angle designed to maximize cutting efficiency when working with dense and heavy materials.

These blades cater to an extensive array of industries and applications, such as packaging, furniture production, automotive manufacturing, and the processing of foam, rubber, cork, and composite materials. Heavier-duty blades like the BW6354 excel in cutting dense foam and other high-resistance substances, making them indispensable tools for challenging projects.

The comparison underscores critical factors when selecting a blade—considerations like the thickness of the material to be cut, the precision of the cutting angle, and the nature of the intended application. This guidance simplifies decision-making, ensuring users can identify the blade most suitable for specific pneumatic or electric oscillating tool cutting tasks.

In addition to blade functionality, Blackman & White offers comprehensive manufacturing solutions for their BW265, BW267, BW354, and BW6354 models. These wave-cutting blades serve both pneumatic and electric oscillating tools across diverse production sectors. Shenzhen Oyea Machinery Co., Ltd specializes in the development and delivery of these high-quality tools, providing customers with seamless integration into their operations through a fully established supply chain. This includes spare parts, consumables, and custom component services available through OEM (Original Equipment Manufacturer) and ODM (Original Design Manufacturer) channels.

The company is committed to delivering exceptional product quality paired with competitive pricing to meet market demands without compromising standards. Backed by a robust manufacturing facility, Shenzhen Oyea consistently delivers precision-crafted tools supported by detailed pricing structures. Their unwavering focus on customer satisfaction anchors their operations, ensuring reliable service through every aspect of production, wholesale distribution, and tailored solutions.

PREV : Zund R108 R141 R202 R203 R204 R208 R209 R503 router bits for zund NEXT : Ruk Rukdp034 Rukdp037 Rukdp038 Rukdp042 Router Bit