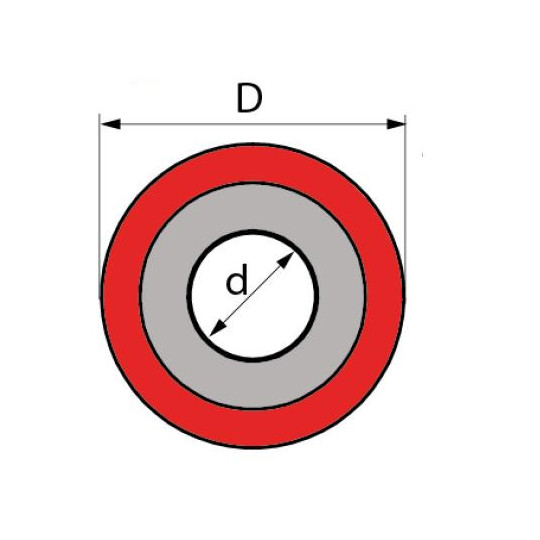

Key Specifications

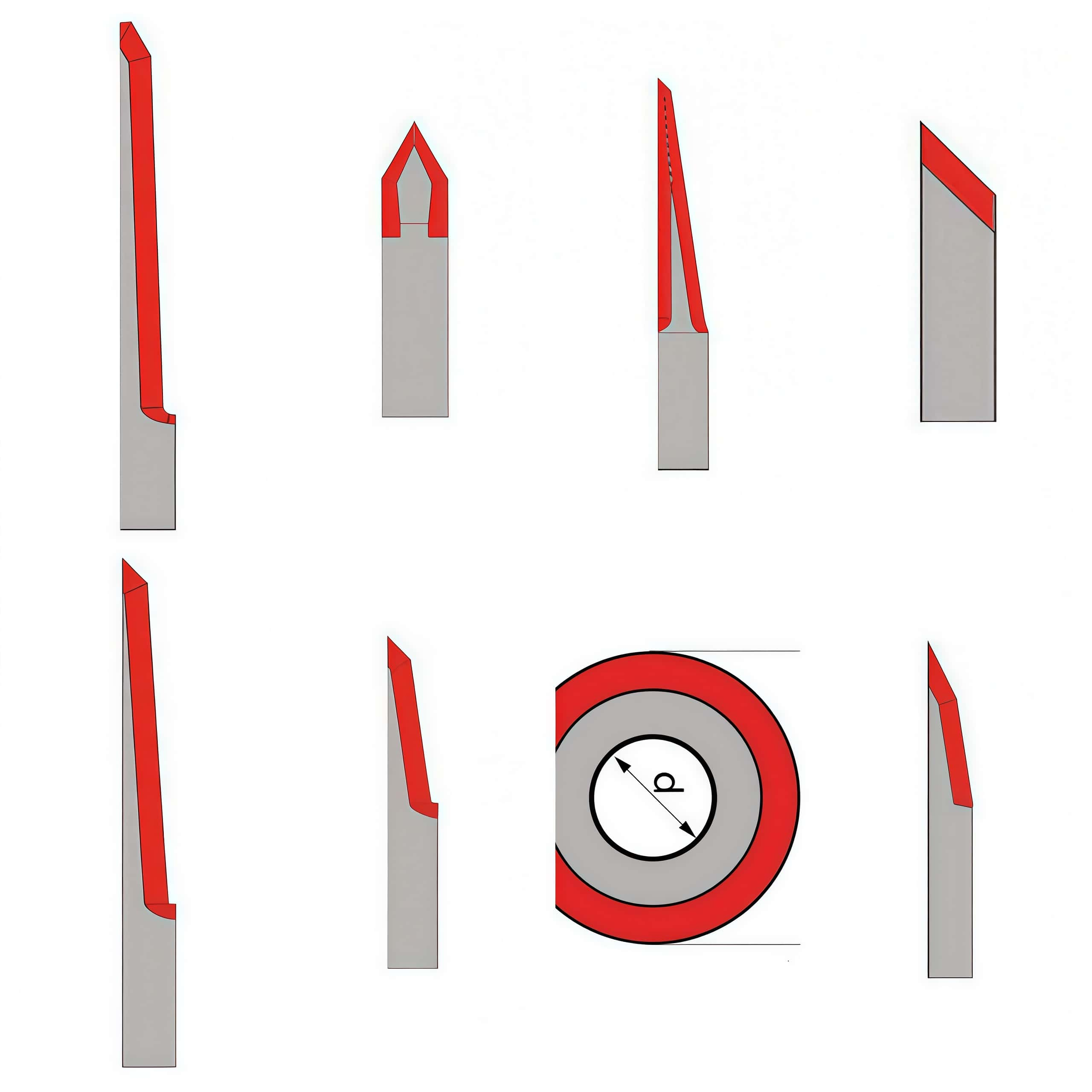

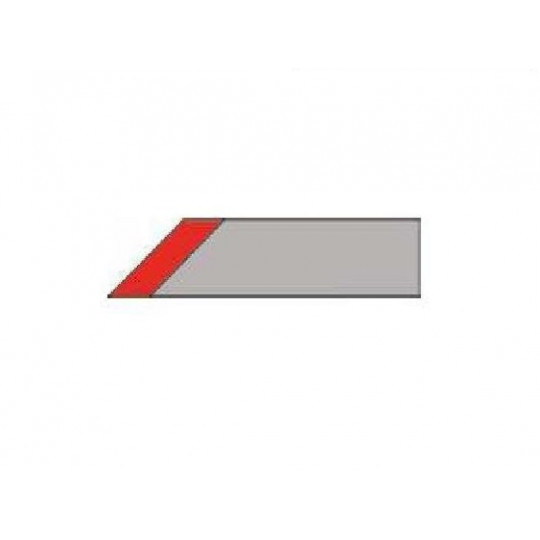

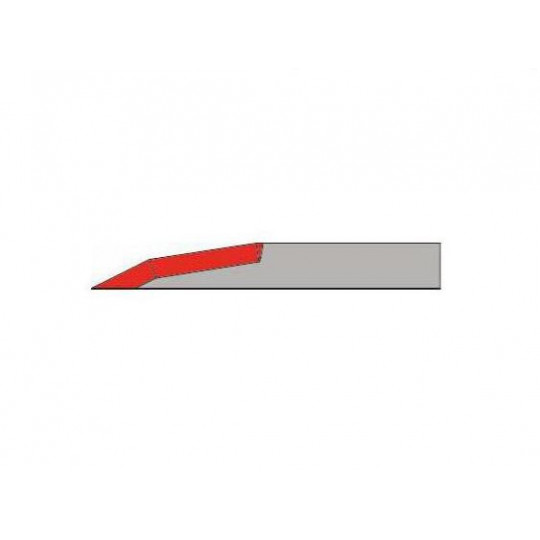

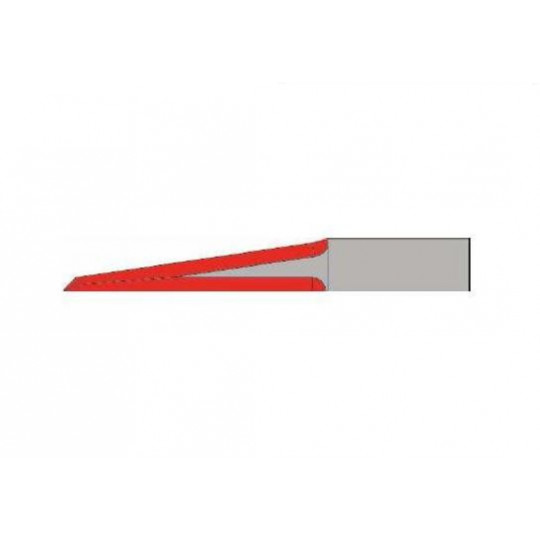

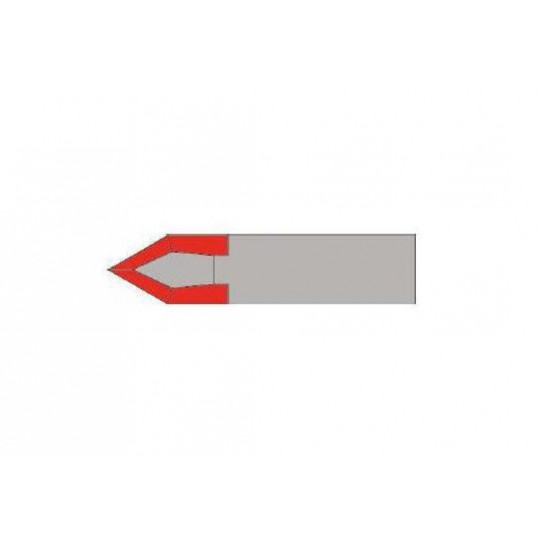

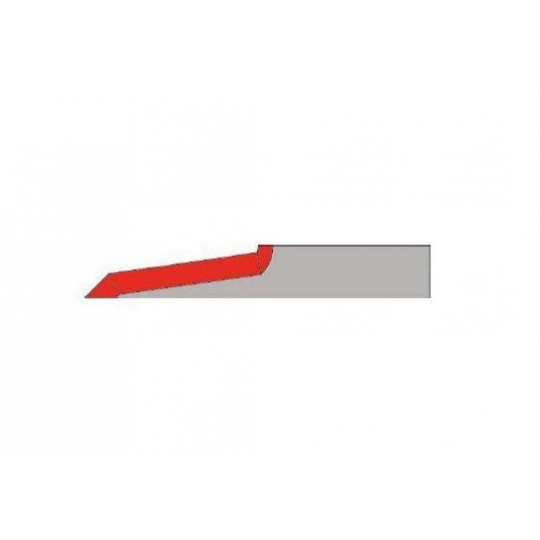

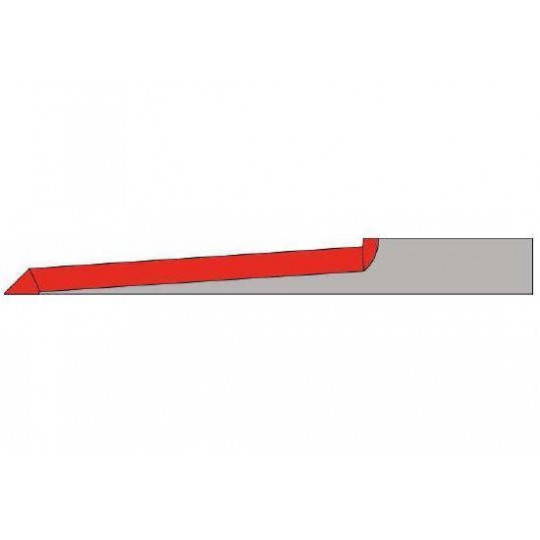

These blades vary in shank type, edge geometry, and cut depth for drag, oscillating, or rotary applications. K2206 belongs to early Protek series with flat shanks around 0.65-1.5mm thick for general-purpose cutting. K6410-FBR and K4210-C feature reinforced designs (FBR indicates fiberboard suitability) with 10-15mm cut lengths and angles like 55-81.5 degrees for denser materials.

Dimensions Comparison

|

Blade Model |

Shank Type/Size |

Cut Length/Depth |

Edge Angle |

Typical Use |

|

Flat, ~0.65x5.6mm |

~5-15mm |

50-55° |

General drag |

|

|

Flat, 1.5mm thick |

10-15mm |

~81° |

Fiberboard, oscillating |

|

|

Flat/centered, 1.5x8mm |

~15mm |

45-55° |

Thick PVC, combo profile |

|

|

Varies, 1-1.5mm |

10mm+ |

45-90° |

Perforating, carton |

|

|

Flat, precision |

15mm |

Single edge, 81.5° |

Abrasive/tough materials |

Compatibility Notes

All fit Protek tool holders, with selections based on material thickness and machine model; verify via CAD/CAM software for speed/feed adjustments. K604-15 and similar -15 series excel in 15mm depths for oscillating knives.How to install and adjust Protek Cnc Knife Blades

Protek CNC knife blades are typically used in oscillating or drag knife systems on CNC routers like the Protek UNICO TT for cutting soft materials such as foam, fabric, and leather. Installation involves securing the blade in its holder and mounting it correctly on the machine, while adjustment focuses on blade depth for precise cuts. Always power off the machine and follow safety protocols before starting.

Installation Steps

Remove the knife cap or collet and loosen the fixing screws or clamp using an Allen key. Insert the new blade fully into the holder with the cutting edge facing the correct direction (often toward the fixing screws or X+ axis). Tighten the screws securely, then mount the holder into the tool spindle by aligning it, rotating the locking bolt clockwise, and connecting any plugs.

Adjustment Process

Use the top plunger, knob, or adjustment nut to extend the blade minimally—typically no more than the thickness of a credit card for thin materials. Test by pressing the plunger against scrap material to ensure light contact, then fine-tune by loosening a lock nut, twisting the adjuster, and retightening. Perform a test cut to verify depth and alignment, checking for clean penetration without excessive vibration.

Common Tips

Match blade angle (e.g., 45° or 60°) to material thickness.

Avoid over-extension to prevent blade damage or base layer cuts.

Recalibrate Z-height after changes for optimal performance

PREV : Lưỡi dao cắt rung động tiếp tuyến COMELZ NEXT : Zund텅스텐강 디지털 칼날-커팅기 호환 교체 적용 대상