The life of the cutting tool can reach about 2000 meters. As for the life, it is mainly affected by the cutting material and the appropriate pressure. It is best to do a test cut every time to confirm the knife pressure and cutting depth and speed, which can also extend the life of the tool.

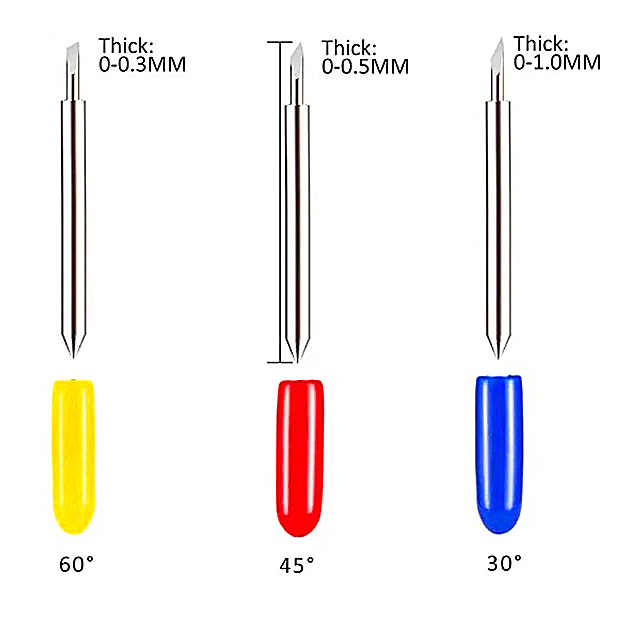

30-degree cutting knife (yellow rubber sleeve) is used for thin materials, such as inkjet stickers, photo stickers, car stickers, paper within 240 grams, 3M stickers, PU/PVC thermal transfer film, sticky notes, etc.

60-degree cutting knife (blue rubber sleeve) is used for relatively thick materials, such as non-woven fabrics, magnetic rubber (magnetic stickers), leather, transfer paper or cardboard above 300 grams

45-degree cutting knife (red rubber sleeve) is used for medium-thick materials, 240-300 grams of paper, reflective film, PVC film, inkjet photo paper, etc.

Generally speaking, the larger the angle number 60>30, the thinner the material is. In addition, there is a 15-degree knife suitable for thicker cutting. (Desktop engraving machines are usually equipped with 45-degree knives)

FAQ

1: When cutting stickers, the surface is not smooth and has sharp teeth?

When cutting thin materials such as stickers, a 45-degree knife should be used. Because the material is relatively thin, a small-angle knife (sharp tip) will not be smooth on the surface of the material, so this situation will occur.

FAQ

2: Why do I cut through the base paper even though the pressure has been reduced to the minimum when cutting label paper?

The tip of the knife is too long when installed in the knife holder. Since the label paper is thin, you only need to shorten the tip of the knife when it is installed.

FAQ

3: Why do knives break so often?

Reason 1: The length of the tip of the knife is adjustable. We generally recommend that the tip of the knife should not be too long, which can extend the service life of the knife. Reason 2: Choose the knife according to the thickness of the material.

FAQ

4: The newly purchased knife does not cut well

The cutting effect is obviously different due to different specifications of the knife, such as the diameter and length of the knife rod.

FAQ 5:

Why is the knife I bought this time different from the one that came with the previous machine?

The knife that comes with the machine is installed in the knife holder. To protect the tip of the knife and prevent it from being damaged during transportation, the separately purchased knife is protected by three color knife covers: red, blue, and yellow. When using it, just take off the knife cover to see the tip of the knife. When installing it, insert one end of the cone into the knife holder with the angled end facing outward.

Basically, the life of the lettering knife can reach about 2,000 meters. As for the life, it is mainly affected by the cutting material and the appropriate pressure. It is best to do a test cut every time to confirm the knife pressure, cutting depth and speed, which can also extend the life of the knife.

When replacing a new knife, the sharpness of the blade cannot be tested with fingers, and it cannot be scratched on paper in the hand. It should be installed in the knife holder and turned on to test the knife.

When engraving small characters, small patterns, and thick paper, the speed should be slow. When engraving paper, the knife pressure should be moderate. The size of the pressure directly affects the life of the engraving knife (new knife has low pressure, and thick paper has old knife has high pressure). The engraving knife should not extend too long from the knife seat. Generally, it is better to extend it within 1mm. At the same time, pay attention to extend it longer when engraving small characters to avoid the knife seat taking away the engraved pattern on the sticker. It is better to use a new engraving knife and slow down the speed when engraving small characters. Engraving large characters is not so particular.

When the engraved characters are easy to peel off on one side and difficult to peel off on the other side, it is considered that the machine pressure strip is seriously damaged and needs to be replaced

Vinyl Cutter Blades,Plotter Cutting Blades

PREV : Oscillating Knife Cutting Machine Head Selection and Comparison between Circular Knife and Oscillati NEXT : Shop SUMMA T-Series Tangential knives knife Blade production manufacturing wholesale sales