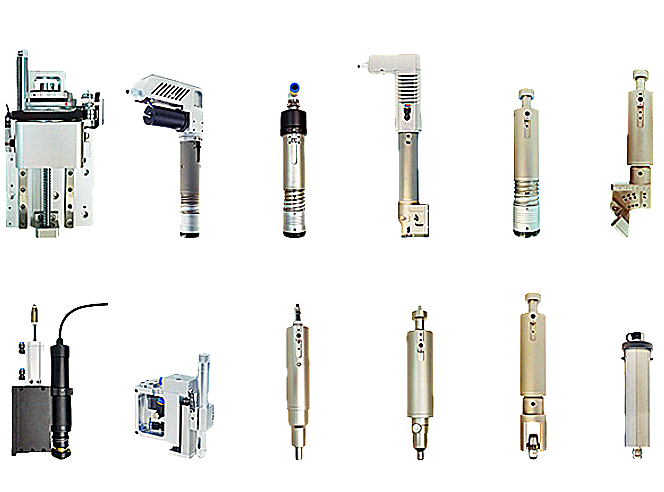

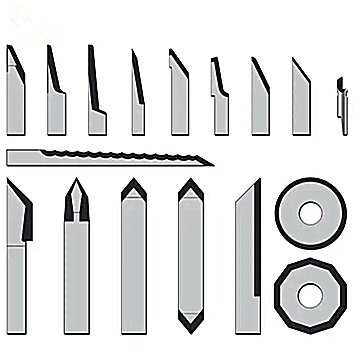

The oscillating knife cutting machine can be equipped with a variety of knives to meet the processing needs of different materials. The following are common knife types and their applicable materials:

Oscillating knife: Cutting is achieved through the high-speed reciprocating motion of the blade. It is suitable for various flexible materials such as cloth, leather, cardboard, KT board, ABS plastic, corrugated paper, sponge, foam board, sealing ring, carbon fiber prepreg, etc.

Circular knife: The motor drives the blade to rotate at high speed for cutting. It is particularly suitable for processing woven materials and textiles, such as wool velvet, blackout cloth, carbon fiber, banners, flags, UV cloth, etc.

Drag knife: Cutting is achieved through the rapid movement of the knife. It is characterized by fast speed and low maintenance cost. It is suitable for cutting thin materials such as car stickers, cardboard, imitation leather, PP paper, soft glass, thin plastic, rubber cloth, reflective stickers, ABS plastics, etc.

Half-cut knife: Used to half-cut materials, commonly used in the processing of materials such as self-adhesive stickers, magnetic stickers, PP glue, rubber cloth, reflective stickers, etc.

Bevel cutter: Through the tilt installation at different angles, bevel processing and V-groove processing can be achieved. It is suitable for soft glass, PVC, corrugated paper, honeycomb board, KT board and other materials.

Punching knife: The motor drives the spindle to rotate at high speed, and the cylinder drives the spindle up and down to achieve punching and cutting of materials. It is suitable for materials such as leather, imitation leather, cloth, kraft paper, PVC, EVA, etc.

Brush knife: After installing the brush, you can mark, write, draw patterns on the material, etc. It is suitable for most materials such as cloth, leather, cardboard, plastic, glass, etc.

When choosing a knife, you should choose the appropriate type of knife according to the characteristics of the processing material and the processing requirements to ensure the best cutting effect and production efficiency.

Comparison between vibrating knife and circular knife

Cutting method: The vibrating knife achieves cutting through the high-speed reciprocating vibration of the blade, while the circular knife cuts through the high-speed rotation of the blade.

Applicable materials: Vibrating knives are suitable for various flexible materials, such as cloth, leather, foam, etc.; circular knives are more suitable for cutting woven materials and textiles, such as wool velvet, blackout cloth, etc.

Cutting effect: The cutting section of the vibrating knife is smooth, which is suitable for occasions with high cutting quality requirements; the circular knife may produce burrs on some materials due to rotary cutting, but it works well when cutting textiles.

In summary, vibrating knives and circular knives have their own advantages, and they should be reasonably configured according to the specific processing materials and process requirements.

PREV : How To Choose Different Types Of Cutting Tools And Blades For Esko Kongsberg Cutting Systems NEXT : How long is the life of the blade of a computer plotter? How often should it be replaced?