The Zund Z16 and Zund Z17 tungsten carbide knife blades are both designed for use in Zund automated cutting machines, but they have distinct differences in their specifications and applications:

Zund Z16 Knife Blade

- Cutting Angle: 54°

- Maximum Cutting Depth: 7.4 mm

- Blade Thickness: 0.63 mm

- Blade Length: Typically around 26 mm

- Shaft Width: Approximately 5.6 mm

- Materials: Suitable for cutting soft materials like canvas, self-adhesive vinyls, reflective vinyls, folding carton, magnetic foil, paper, polyester fabric, PVC banner, and foam board.

- Tools: Compatible with Electric Oscillating Tool (EOT) and Pneumatic Oscillating Tool (POT).

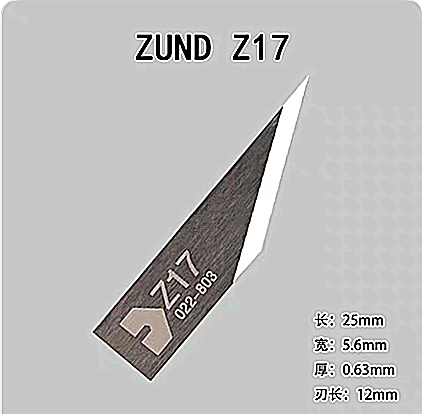

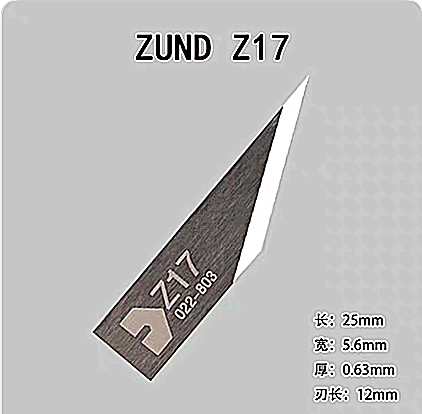

Zund Z17 Knife Blade

- Cutting Angle: 65°

- Maximum Cutting Depth: 12 mm

- Blade Thickness: 0.63 mm

- Materials: Ideal for cutting thinner materials with a smaller overcut, exerting more drag force than the Z16. Suitable for materials like folding carton, gasket material, foam, leather, and various packaging materials.

- Tools: Also compatible with EOT and POT.

Key Differences:

- Cutting Angle and Depth: Z17 has a steeper cutting angle (65°) and deeper cutting capability (12 mm) compared to Z16 (54° and 7.4 mm).

- Material Handling: Z17 is designed for thinner materials with a focus on precision and less overcut, while Z16 is more versatile for a broader range of soft materials.

- Drag Force: Z17 exerts more drag force, which can be beneficial for certain materials but may require more power or adjustment in cutting settings.

Shenzhen Oyea Global sales: ensuring availability across Europe, the USA, the Middle East, and Asia with efficient shipping and customer service.Sold To Germany, France, The United Kingdom, Poland, The United States, Russia, Vietnam, Thailand, Indonesia, Singapore, The Netherlands, Switzerland, South Korea, Japan, Turkey, The Philippines, Hong Kong, Taiwan, Italy, Spain, Hungary, The Czech Republic And Other Countries Or Regions

PREV : Atom Aristo Zund Summa Iecho Cnc Router Knife Blades Differ In Wear Resistance And Sharpness NEXT : Bullmer 109148 108065-S 103986 105935-B CNC Cutter Knife Blades Sales Store Shop