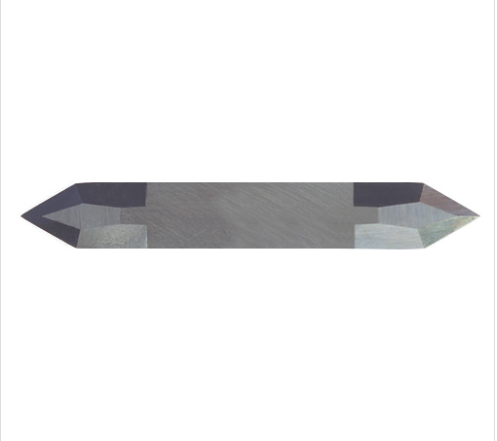

- Z44 Blade: This is a double-sided drag blade, typically used for cutting less tough and fibrous materials like carpet or tarpaulin. It has a thickness of 1.5 mm and is designed for flat-stock cutting.

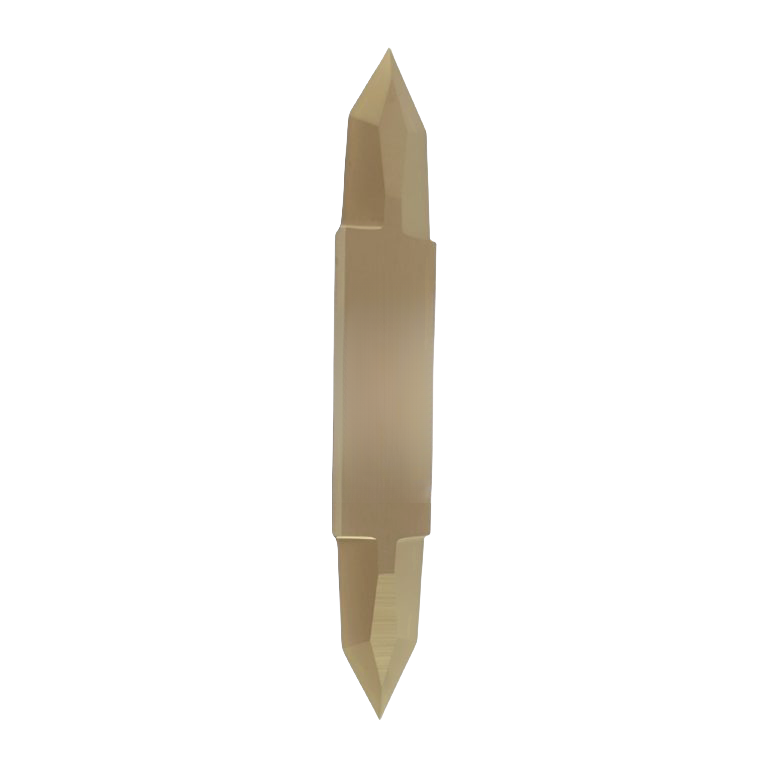

- Z45 Blade: The Z45 is often described as an upgraded version of the Z44, also featuring blades on both ends. It is designed to offer improved performance over the Z44, possibly in terms of durability or cutting efficiency.

2. Material Usage:

- Z44 Blade: Suitable for fibrous materials, carpets, and tarpaulins.

- Z45 Blade: While specific material usage is not detailed, it is implied to be versatile and potentially more effective than the Z44 for various materials.

General Characteristics:

Both the Z44 and Z45 are flat-stock drag blades made from tungsten carbide. This means they are designed for drag cutting, where the blade is pulled through the material.

They are used in Zund digital cutting machines.

They are designed for cutting a wide variety of materials.

Key Differences and Similarities:

While both are tungsten carbide blades, there can be subtle differences in their geometry, edge sharpness, and intended applications. Unfortunately getting precise detailed specs is hard.

Coating variations exist for both blades. It is common to find coatings such as:

TiN (Titanium Nitride): This coating increases hardness and wear resistance. So you will often find Z44C, and Z45C, naming conventions.

DLC (Diamond-Like Carbon): this is another type of coating that increases hardness and wear resistance. This is seen on some Z44 blades.

Therefore, the main difference between the blades can be found by researching the specific coating that the blades may have.

It is important to remember that many 3rd party producers of Zund compatible blades also exist, and those producers may also change small aspects of the blades design. So that could also change some of the blades properties.

Applications:

They are used in conjunction with various Zund cutting tools, like the Universal Cutting Tool (UCT), to process materials like:

Cardboard

Vinyl

Foam board

And many other flexible or semi rigid materials.

In summary, while they share a base material and function, coating variations and subtle design nuances can differentiate the Z44 and Z45 blades. For specific application needs, it is always recommended to consult OYEA

Shenzhen Oyea Global sales: ensuring availability across Europe, the USA, the Middle East, and Asia with efficient shipping and customer service.Sold To Germany, France, The United Kingdom, Poland, The United States, Russia, Vietnam, Thailand, Indonesia, Singapore, The Netherlands, Switzerland, South Korea, Japan, Turkey, The Philippines, Hong Kong, Taiwan, Italy, Spain, Hungary, The Czech Republic And Other Countries Or Regions

PREV : Atom Kimla Polska Grupa Cnc Seron Tungsten Steel Blade Compatibility Replacement Applicable NEXT : How do I select the right CNC knife blades for my Protek machine