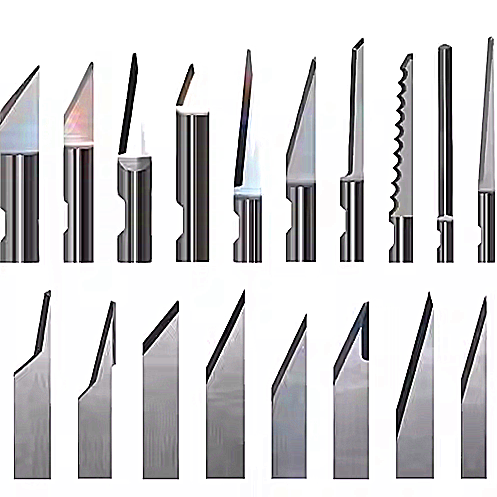

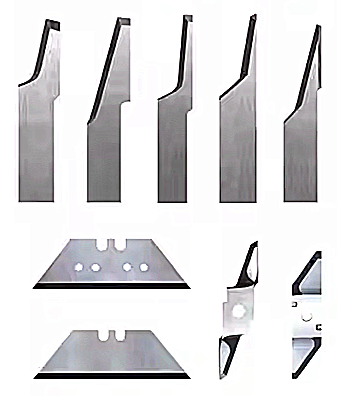

Flatbed cutting machine blades are typically made from tungsten carbide steel rather than pure tungsten steel. Tungsten carbide is an extremely hard and wear-resistant material, ideal for precision cutting applications.

1. Type of Tungsten Steel Used:

The blades are commonly made from:

Tungsten Carbide (WC-Co): A composite material of tungsten carbide particles bound with cobalt (Co) or nickel (Ni). Common grades include YG6, YG8, YG10, YG15, where "YG" refers to "hard alloy" in Chinese classification, and the number represents the percentage of cobalt.

High-Speed Steel (HSS) with Tungsten Additives: Some blades use HSS with tungsten (e.g., W18Cr4V) to improve wear resistance.

2. Production Process of Tungsten Carbide Blades

The manufacturing process involves several steps:

1. Raw Material Preparation

Tungsten carbide (WC) powder is mixed with a cobalt or nickel binder (typically 5-15% cobalt).

Other additives (e.g., titanium carbide for additional hardness) may be included.

2. Mixing & Milling

The powder is ball-milled with a solvent and binder to ensure uniform distribution.

This process helps control particle size and enhances the final hardness.

3. Drying & Granulation

The mixture is dried to remove moisture and then granulated for better compaction.

4. Pressing (Compaction)

The powdered mixture is pressed into blade shapes using high-pressure molds.

This step forms a "green compact" (a loosely held blade shape).

5. Sintering

The green compact is sintered at 1300–1500°C in a vacuum or hydrogen furnace.

The cobalt binder melts, binding the tungsten carbide particles together, forming a dense and hard structure.

6. Precision Grinding & Sharpening

The sintered blades are ground with diamond grinding wheels to achieve a razor-sharp cutting edge.

Surface finishing ensures smoothness for precision cutting.

7. Coating (Optional)

Some blades receive TiN (Titanium Nitride) or TiAlN (Titanium Aluminum Nitride) coatings to improve wear resistance and reduce friction.

8. Quality Inspection

Hardness, toughness, and sharpness are tested to ensure performance.

Final blades are packaged for use in flatbed cutting machines.

Would you like recommendations on specific tungsten carbide grades based on your application?

PREV : Colex Sharpcut Sx Sxc Px Series Flatbed Cutters Blades And Tools NEXT : What are the differences between the Gerber TL-051 and TL-052 Tangential plotter blade