Solid Tungsten Carbide (VHM) knives are indeed a premium option for CNC digital cutting systems like Zund, Summa, Roland, Atom, Gerber, Aristo, Esko, and iEcho. Here's a breakdown of their key features and benefits:

What are Solid Tungsten Carbide (VHM) Knives?

Material: These knives are made entirely from Tungsten Carbide, a very hard and dense composite material. It consists of fine grains of tungsten carbide bonded together by a metal binder, typically cobalt.

VHM (Very High Hardness Material): This designation highlights the exceptional hardness of the tungsten carbide used, leading to superior wear resistance.

Advantages of Solid Tungsten Carbide VHM Knives:

Exceptional Hardness: Tungsten carbide is significantly harder than steel alloys, allowing the knives to maintain a sharp cutting edge for a much longer time.

Superior Wear Resistance: Due to their high hardness, these knives exhibit excellent resistance to abrasion and wear, especially when cutting abrasive materials.

Extended Blade Life: Compared to steel blades (including high-speed steel and stainless steel), solid tungsten carbide knives offer a significantly longer lifespan. This reduces the frequency of blade changes, leading to less downtime and increased productivity.

Cleaner and More Precise Cuts: The ability to hold a sharp edge for longer results in cleaner, smoother, and more precise cuts, minimizing material waste.

Improved Productivity: Fewer blade changes mean less interruption to the cutting process, leading to higher throughput.

Key Features of VHM Knives:

-

Material: Made from solid tungsten carbide, known for its wear resistance and strength.

-

Precision: Ground to very fine tolerances for clean and accurate cuts.

-

Longevity: Longer life compared to high-speed steel (HSS) or coated blades.

-

Compatibility: Designed to fit popular digital cutting systems like:

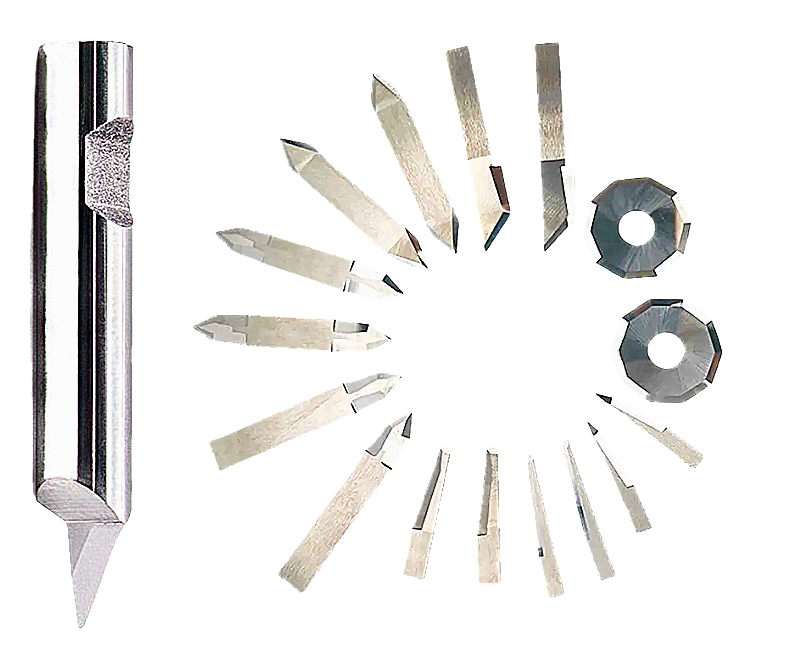

Types of Blades Available:

-

Drag knives

-

Oscillating knives (electric or pneumatic)

-

Tangential blades

-

Perforation blades

-

Kiss-cutting blades

-

V-cut blades

-

Scoring blades

Applications:

These VHM knives are widely used in industries such as:

-

Packaging

-

Sign & display

-

Automotive

-

Aerospace

-

Apparel and textiles

-

Gasket manufacturing

OYEA: Offers a wide range of solid tungsten carbide knives specifically designed for Zund, Summa, iEcho, ESKO, Roland, Atom, Aristo, Jwei, and Gerber machines. They also offer custom blade design.

Supplies tungsten carbide oscillating knives and other types of blades compatible with various CNC cutting machines, including iEcho, Jwei, Atom, and Elitron.

In conclusion, solid tungsten carbide VHM knives are a high-performance cutting tool option for CNC digital cutting systems when dealing with demanding materials and requiring extended blade life, precision, and productivity. While the initial cost is higher, the long-term benefits in terms of reduced downtime, waste, and improved cut quality can often justify the investment.

When selecting solid tungsten carbide VHM knives, it's crucial to choose the correct blade geometry, size, and shank type specifically designed for your cutting machine and the materials you are processing. Consulting with your machine supplier or a reputable knife manufacturer is recommended to ensure optimal performance and longevity.

Shenzhen Oyea Global sales: ensuring availability across Europe, the USA, the Middle East, and Asia with efficient shipping and customer service.Sold To Germany, France, The United Kingdom, Poland, The United States, Russia, Vietnam, Thailand, Indonesia, Singapore, The Netherlands, Switzerland, South Korea, Japan, Turkey, The Philippines, Hong Kong, Taiwan, Italy, Spain, Hungary, The Czech Republic And Other Countries Or Regions

PREV : About Aristo Axyz Colex Esko Kongsberg Zund Multicam Cnc Router Knife Blades Price NEXT : Kartech Blade For Kartech Flatbed And Digital Cutting Machines