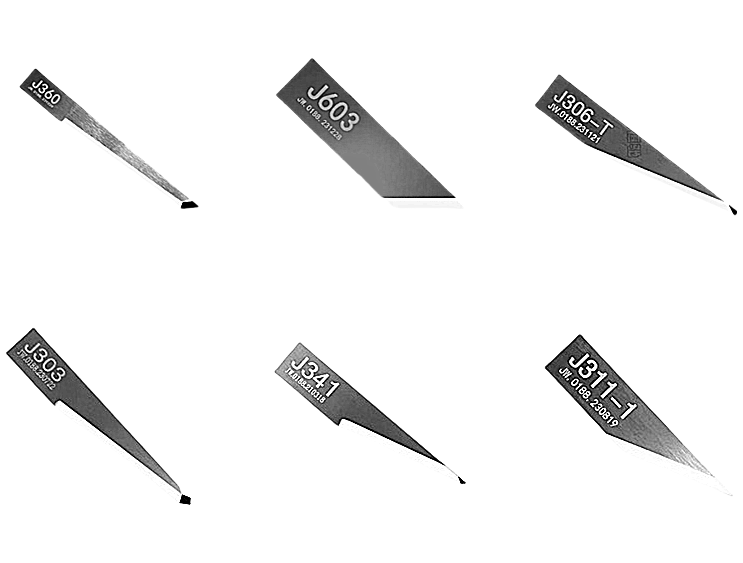

How to choose JWei J311-1 J341 J303 J306 J603 J360 Knife Blades For JWei Cutting Systems

When choosing JingWei (JWei) knife blades such as J311-1, J341, J303, J306, J603, and J360 for digital cutting systems, the selection depends primarily on the material to be cut, the required cutting depth, blade dimensions, and blade angle. Here is a detailed guide to help you choose the right blade:

Key Parameters to Consider

· Blade Dimensions: Length, width, and thickness affect compatibility with your cutting machine and the type of cut.

· Blade Angle: Determines the cutting efficiency and suitability for different materials.

· Cutting Depth: Maximum thickness of material the blade can effectively cut.

· Material Type: Different blades are optimized for materials like cardboard, corrugated board, leather, rubber, textiles, etc.

· Blade Type: Oscillating, tangential, rotary, or kiss-cut blades serve different cutting methods.

Overview of Specific JWei Blades

|

Blade Model |

Dimensions (mm) |

Angle (°) |

Max Cutting Depth (mm) |

Suitable Materials |

Notes |

|

25 x 5.5 x 0.63 |

64° / 26° |

≤ 10 mm |

Chevron board, corrugated cardboard, folding carton |

Oscillating knife, good for medium thickness cardboard |

|

|

33 x 6.35 x 0.63 |

74° / 16° |

≤ 18 mm |

Cardboard, corrugated cardboard, paper |

Oscillating tangential knife, suitable for thicker cardboard |

|

|

38 x 6.3 x 0.63 |

80° / 10° |

≤ 23 mm |

Folding carton, honeycomb |

Oscillating knife, ideal for thicker folding cartons and honeycomb |

|

|

30 x 5.5 x 0.63 |

74° / 16° |

≤ 13 mm |

Corrugated cardboard, paper |

Oscillating knife, flat top, for corrugated cardboard |

|

|

22 x 5.5 x 0.63 |

45° / 45° |

≤ 5 mm |

Carton, paper, leather, PVC, carbon fiber, rubber |

Oscillating tangential knife, for thin to medium materials |

|

|

(Not detailed in search results) |

- |

- |

Typically used for similar materials as other oscillating blades |

Usually for medium thickness materials (inferred from similar models) |

How to Choose the Right Blade

1. Identify the Material to Cut

For thin materials like vinyl, stickers, or paper, blades like J301 (kiss-cut) are preferred.

For corrugated cardboard and folding cartons, choose blades like J311-1, J306, or J303 depending on thickness.

For thicker or tougher materials like honeycomb or composite boards, J303 or J341 are better suited due to their larger cutting depth and blade angle.

For leather, rubber, or carbon fiber, tangential knives such as J603 are recommended.

2. Consider Cutting Depth

Match the blade’s maximum cutting depth with your material thickness.

For example, J311-1 cuts up to 10mm thick materials, while J303 can handle up to 23mm.

3. Blade Angle and Shape

A sharper angle (e.g., 45°/45° in J603) is suitable for precision cuts on thinner materials.

Larger angles (e.g., 74°/16° in J306 or J341) are better for thicker or tougher materials.

Flat-top blades (like J306) provide stability and clean cuts on corrugated cardboard.

4. Machine Compatibility

Ensure the blade dimensions fit your JWei cutting system or compatible digital cutters.

Many JWei blades are interchangeable with other brands like Zund or Esko due to standardized sizes.

5. Cutting Method

Oscillating blades are versatile for tough materials.

Tangential knives provide precise corner cuts and are good for complex shapes.

Rotary blades (not listed here) are better for textiles.

Summary Table for Quick Reference

|

Blade |

Max Cut Depth |

Material Focus |

Blade Type |

Notes |

|

≤ 10 mm |

Chevron board, cardboard |

Oscillating knife |

Medium thickness cardboard |

|

|

≤ 18 mm |

Cardboard, corrugated board |

Oscillating tangential |

Thicker cardboard |

|

|

≤ 23 mm |

Folding carton, honeycomb |

Oscillating knife |

Thicker folding cartons |

|

|

≤ 13 mm |

Corrugated cardboard, paper |

Oscillating knife |

Flat top for stability |

|

|

≤ 5 mm |

Carton, leather, PVC, rubber |

Oscillating tangential |

Thin to medium materials |

|

|

(Varies) |

Medium thickness materials |

(Likely oscillating) |

Check specific specs if needed |

Additional Tips

· Always verify blade thickness and compatibility with your cutter.

· Consider blade wear and replacement frequency based on material abrasiveness.

· Consult your cutter’s manual or supplier for specific blade recommendations.

This guidance is based on detailed JingWei JWei blade specifications and cutting applications from trusted suppliers and industry overviews.

Shenzhen Oyea Global sales: ensuring availability across Europe, the USA, the Middle East, and Asia with efficient shipping and customer service.Sold To Germany, France, The United Kingdom, Poland, The United States, Russia, Vietnam, Thailand, Indonesia, Singapore, The Netherlands, Switzerland, South Korea, Japan, Turkey, The Philippines, Hong Kong, Taiwan, Italy, Spain, Hungary, The Czech Republic And Other Countries Or Regions

PREV : Summa Aristo Gerber Esko Roland Zund Knives And CNC Knife Blades Are Widely Sold And Distributed NEXT : Atom Kimla Polska Grupa Cnc Seron Tungsten Steel Blade Compatibility Replacement Applicable