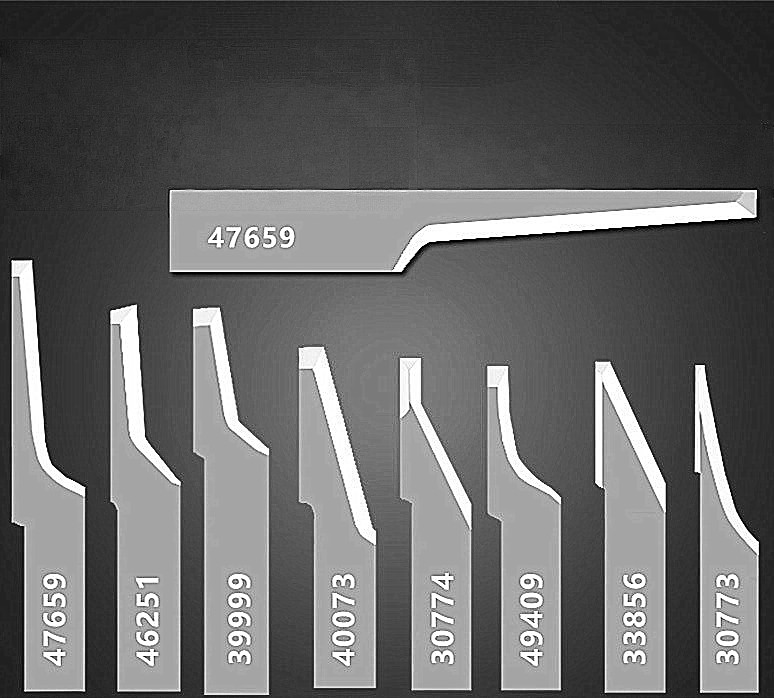

The ATOM cutting machine blades 46251, 47659, 30773, 39895, and 49409 differ mainly in their intended applications, cutting depth, and material compatibility, although they share some common features such as thickness and composition.

Common Features

· Most ATOM blades have a thickness around 0.63 mm.

· They are typically made of tungsten carbide (HM - hard metal), ensuring durability and sharpness.

· Designed for use with electric oscillating tools and pneumatic oscillating tools.

Specific Differences

|

Blade Model |

Max Cutting Depth |

Material Suitability |

Special Features |

|

~0.63 mm thickness, cutting angle ~5°+ |

General purpose cutting, suitable for various materials (exact details limited) |

Standard blade thickness and angle for versatile use |

|

|

Up to 19 mm |

Very rigid materials, leather soles (3-4 mm), belts, reinforced graphite, asbestos-free materials up to 10 mm thickness |

High-speed cutting knife, ideal for small radii cuts on tough materials |

|

|

Max. Cutting depth |

General tungsten steel blade, high quality, long service life |

Standard oscillating blade made of tungsten steel, suitable for various cutting tasks |

|

|

Max. Cutting Depth |

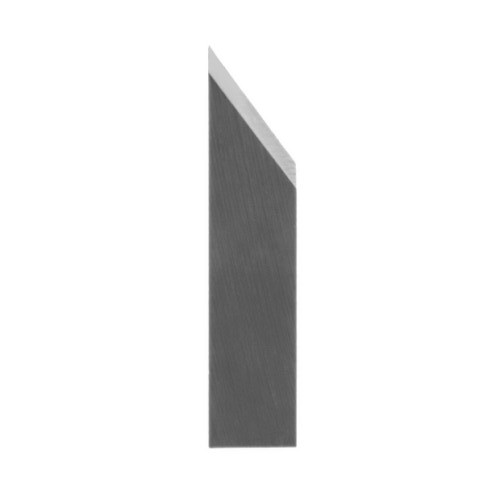

High-quality thin, sharp-pointed oscillating knife for CNC machines |

Precision blade for non-standard products, sharp and durable edge |

|

|

Similar to 46251, around 0.63 mm thickness |

General cutting blade, details similar to other standard ATOM blades |

Standard blade for multiple applications, likely similar to 46251 |

Summary

· 47659 stands out for cutting very rigid and thicker materials (up to 19 mm), including leather and reinforced graphite, with high speed and precision for small radii.

· 46251 and 49409 are more general-purpose blades with standard thickness and cutting angles, suitable for a variety of materials.

· 30773 is a tungsten steel oscillating blade known for durability and long life.

· 39895 is a precision, thin, sharp-pointed blade designed for CNC cutting of complex or non-standard shapes.

These differences suggest that selection depends on the material type and thickness you need to cut, with 47659 being specialized for tougher, thicker materials, while the others serve more general or precision cutting roles.

Shenzhen Oyea Global sales: ensuring availability across Europe, the USA, the Middle East, and Asia with efficient shipping and customer service.Sold To Germany, France, The United Kingdom, Poland, The United States, Russia, Vietnam, Thailand, Indonesia, Singapore, The Netherlands, Switzerland, South Korea, Japan, Turkey, The Philippines, Hong Kong, Taiwan, Italy, Spain, Hungary, The Czech Republic And Other Countries Or Regions

PREV : Atom 01046251 01046484 01047659 Cnc Cutting Blade Selection And Application Comparison NEXT : Test Results: Wear Life Of Atom 01039999 Knife Blade Vs Competitors