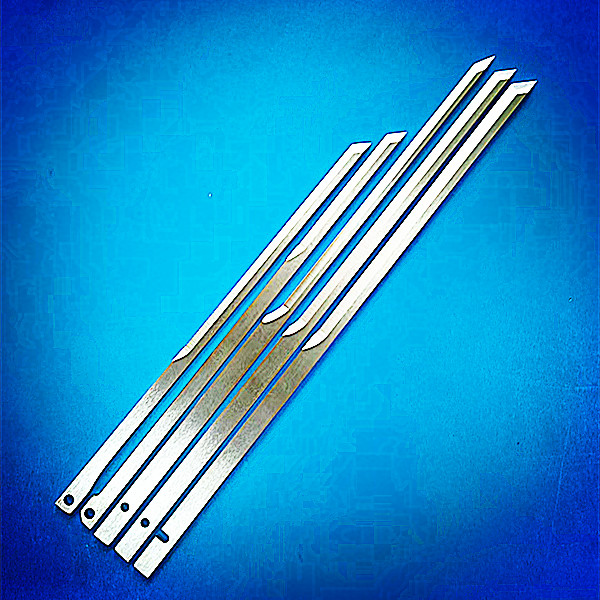

How to Choose and Use Gerber HSS Multi-Layer CAD Cutting Knife Blades

Choosing Gerber HSS Multi-Layer CAD Cutting Knife Blades

1.Blade Compatibility and Model

Select blades that are compatible with your specific Gerber cutting machine model, such as the Gerber GTXL, GT5250, S-91, S-93, or S7200 series. Each model has specific blade sizes and types, for example, the Gerber GTXL uses 25mm HSS multi-layer CAD cutting knife blades (part number 085878000).

2.Blade Material and Quality

Gerber HSS (High-Speed Steel) multi-layer blades offer durability and toughness suitable for cutting multiple layers of material. HSS blades maintain sharpness and resist wear, making them ideal for demanding cutting applications.

3.Blade Dimensions and Edge Configuration

Consider the blade thickness, length, and edge type based on the material and cutting precision required. Gerber blades come in various thicknesses (e.g., .078", .093") and edge profiles (flat ground, hollow ground, serrated) to match cutting needs.

4.Blade Coating and Surface Treatment

Some blades may have coatings such as TiN (Titanium Nitride) to enhance hardness and reduce friction, improving blade life and cutting performance.

5.Cutting Application

Choose blades based on the material type (fabric, leather, composites) and the number of layers to be cut simultaneously. Multi-layer blades are designed to handle thicker stacks efficiently.

Using Gerber HSS Multi-Layer CAD Cutting Knife Blades

1.Blade Installation

Carefully install the blade into the Gerber cutter’s blade holder, ensuring it fits securely without play.

Use the appropriate blade length gauge to set the blade protrusion from the holder accurately.

2.Blade Calibration

Calibrate the blade length in the machine controller after installation to ensure correct cutting depth. This involves entering the blade length value via the hand controller or software interface.

oIncorrect calibration is a common cause of improper cutting depth.

3.Cutting Parameters Setup

Set cutting pressure, depth, and velocity according to the material and blade type in the machine’s control software.

Adjust these parameters for both X and Y axes if needed, depending on the material thickness and blade sharpness.

4.Test Cuts and Adjustment

Perform test cuts to verify blade angle and cutting depth. Adjust angular correction and depth settings if the cut is not clean or precise[.

oUse test cut tools like angle or circle tests to ensure blade alignment.

5.Blade Maintenance and Replacement

Monitor blade wear and replace blades when cutting quality degrades.

Some HSS blades can be rotated to use a fresh edge if designed for it, extending blade life[.

Always recalibrate after blade replacement.

6.Safety and Handling

Handle blades carefully to avoid injury.

Follow manufacturer instructions for blade change and disposal.

Summary

Choose Gerber HSS multi-layer CAD blades based on machine compatibility, blade size, material, and coating for your cutting needs[.

Install blades precisely and calibrate blade length in the machine controller to ensure accurate cutting depth.

Adjust cutting parameters and perform test cuts for optimal performance.

Maintain blades by monitoring wear and rotating or replacing blades as needed to sustain cutting quality.

This approach ensures efficient, precise multi-layer cutting with Gerber HSS blades in CAD cutting systems.

PREV : Digital Cutter Powered Pneumatic Oscillating Tool Pot Blades NEXT : Tungsten Carbide Coated Blade Production Manufacturing