Gerber Multi-Layer CAD Cutting Knife Blades Model Specification Dimensions Usage Difference

Here is a detailed overview of Gerber Multi-Layer CAD Cutting Knife Blades including their model specifications, dimensions, usage, and differences:

Gerber Multi-Layer CAD Cutting Knife Blades Overview

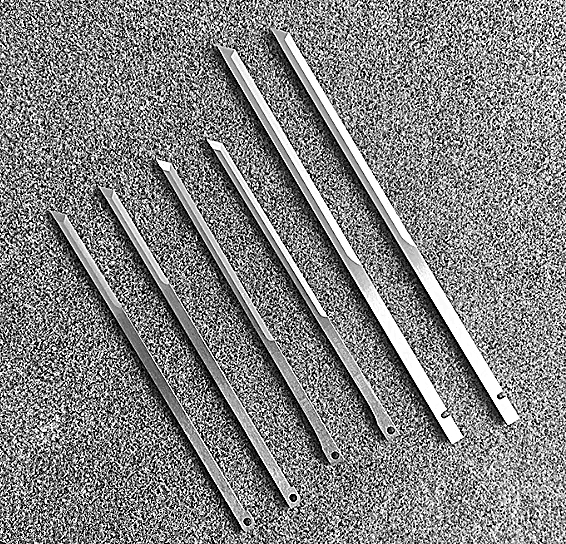

Gerber multi-layer CAD cutting knife blades are designed for use with Gerber cutting machines to efficiently cut multiple layers of materials such as fabric, leather, composites, and technical textiles. These blades are typically made from High-Speed Steel (HSS) and come in various sizes and edge configurations to suit different cutting requirements.

![]()

Model Specifications and Dimensions

|

Model / Part Number |

Compatible Machines |

Blade Height (mm) |

Blade Width (mm) |

Thickness (mm) |

Edge Type |

Material Suitability |

|

Gerber GTXL |

206 |

7.9 |

1.93 |

Multi-layer CAD HSS |

Multi-layer cutting on GTXL |

|

|

Gerber S-91, S-93, S7200, GT7250, Paragon VX, XLc7000, Z7 |

254 |

7.9 |

2.36 |

Hollow ground |

Canvas, carbon fibers, foil, glass fibers, non-woven, polyester, textiles |

|

|

Gerber GT7250, S7200 |

255 |

7.9 |

2.36 |

Multi-layer flat, oscillating knife |

Similar materials as 21261011 |

|

|

General Gerber multi-layer blade |

Approx. 202 |

6.3 |

1.2 (approx.) |

Multi-layer knife |

General multi-layer cutting |

![]()

Usage and Application

· Compatibility: Choose blades compatible with your Gerber cutting machine model (e.g., GTXL, GT5250, S-91, S-93, S7200 series).

· Material Types: Designed for cutting multiple layers of fabrics, leather, composites, and technical textiles such as canvas, carbon fibers, glass fibers, polyester, and non-woven fabrics.

· Blade Installation: Blades must be securely installed in the cutter’s blade holder, with precise blade protrusion set using a length gauge and calibrated in the machine controller for accurate cutting depth

· Cutting Parameters: Adjust cutting pressure, depth, and speed in the machine software according to the blade type and material thickness. Test cuts are recommended to verify blade angle and cutting depth.

· Maintenance: Monitor blade wear and replace or rotate blades when cutting quality declines. Some blades allow edge rotation to extend blade life

· Safety: Handle blades carefully to avoid injury and follow manufacturer instructions for blade changes and disposal.

![]()

Summary

· Gerber multi-layer CAD cutting knife blades are precision tools made primarily from HSS for durability and sharpness in cutting multiple layers of various materials.

· Blade dimensions and edge types vary by model and machine compatibility, with common sizes around 200-255 mm in height, 6-8 mm width, and 1.9-2.4 mm thickness.

· Proper installation, calibration, and cutting parameter adjustment are critical for optimal cutting performance.

· Different models cater to different Gerber cutting machines and cutting applications, with variations in blade size, thickness, and edge profile to suit specific needs.

This detailed specification and usage guide helps users select the appropriate Gerber multi-layer CAD cutting knife blade for their cutting system and materials

PREV : Digital Cutter Powered Pneumatic Oscillating Tool Pot Blades NEXT : Tungsten Carbide Coated Blade Production Manufacturing