Production Process

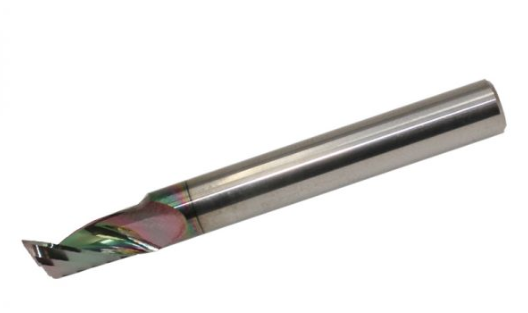

Raw tungsten and carbon powders mix with cobalt binder, then undergo ball milling for uniformity. The mixture compacts under hydraulic pressure into a green body, followed by high-temperature sintering at 1,400-1,500°C to form dense tungsten carbide. For coatings, the sintered carbide particles bond to blade bases via brazing or thermal spraying in controlled furnaces.

Coating Application

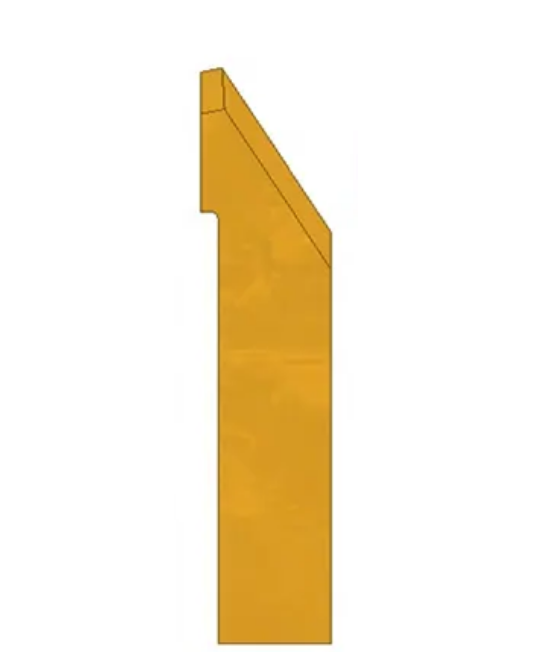

Blades receive tungsten carbide coatings through physical vapor deposition (PVD) or chemical vapor deposition (CVD), depositing fine grit for edge sharpness. Plasma or high-velocity oxy-fuel (HVOF) spraying fuses carbide particles onto the substrate, enhancing corrosion and friction resistance. Finishing includes grinding and polishing to achieve precise geometries.

Quality Control

Dimensional checks, hardness testing (often exceeding 1,500 Vickers), and edge inspections ensure standards. Heat treatments relieve stresses, while surface analyses verify coating adhesion. Blades undergo performance trials simulating industrial use before approval

PREV : Blade Holder Adapter Clip Knife Holder Adapte Clamp Support For Jwei Oscillating Knife Cutting Tool NEXT : Esko Kongsberg Zund Coated DLC Tungsten Steel Blades Introduction–Replacement