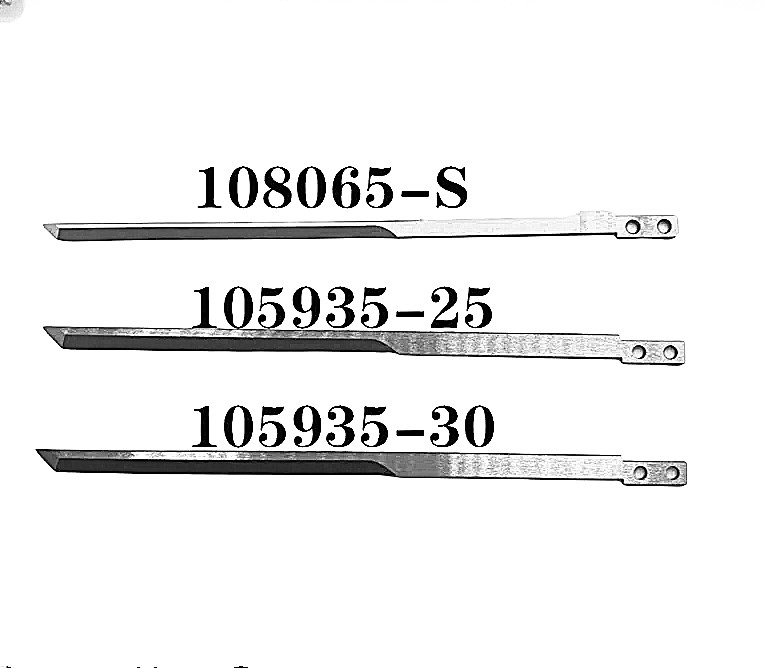

When comparing Bullmer cutter knife blades-specifically the models 108065-S, 105935-25, and 105935-30-it's essential to consider their dimensions, material composition, compatibility, and intended applications to determine the best fit for your cutting needs. Each blade is engineered for precision textile cutting but differs in size and thickness, impacting cutting performance and machine compatibility.

Recommendations and Comparison of Bullmer Cutter Knife Blades

1.Bullmer 108065-S Blade (223mm x 6mm x 2.5mm)

Why Choose This: The 108065-S blade is crafted from high-speed steel (HSS), which offers superior durability and maintains sharpness longer than standard steel blades. Its 6mm width and 2.5mm thickness strike a balance between precision and robustness, making it ideal for detailed cuts without sacrificing blade life.

Distinctive Features: Designed for Bullmer Procut L 5001 and XL 7501 machines, this blade supports smooth cutting with a “smooth” style edge, ensuring clean cuts on textiles and fabrics.

Advantages: High-speed steel construction enhances longevity and cutting accuracy, reducing downtime for blade changes. Its moderate width is versatile for various textile thicknesses.

Drawbacks: The 6mm width may be less suitable for extremely thick or multi-layered materials compared to wider blades.

Best For: Users needing a reliable, durable blade for general textile cutting with a focus on precision and longevity.

2.Bullmer 105935-25 Blade (223mm x 8mm x 2.5mm)

Why Choose This: This blade offers a wider cutting edge (8mm) while maintaining the same length and thickness as the 108065-S. The increased width provides enhanced stability and strength, ideal for cutting thicker fabrics or multiple layers.

Distinctive Features: Also made from high-speed steel, the 105935-25 blade is designed for Bullmer auto-cutting machines, ensuring compatibility and optimal performance.

Advantages: The wider blade width improves cutting stability and reduces blade flex, which is beneficial for heavy-duty cutting tasks. It is corrosion-resistant, adding to its durability.

Drawbacks: The wider blade may sacrifice some precision in very fine or intricate cuts compared to narrower blades.

Best For: Textile manufacturers or users working with thicker materials or multi-layered fabrics who require a robust blade that can handle heavier cutting loads.

3.Bullmer 105935-30 Blade (223mm x 8mm x 3.0mm)

Why Choose This: This variant increases the blade thickness to 3.0mm while keeping the length and width the same as the 105935-25. The thicker blade enhances durability and lifespan, especially under intensive cutting conditions.

Distinctive Features: The extra thickness makes it more resistant to wear and deformation, which is advantageous in high-volume production environments.

Advantages: Greater thickness means longer blade life and better resistance to bending or chipping. It maintains cutting precision while improving robustness.

Drawbacks: Slightly thicker blades may require machines calibrated for this size and could be less nimble for extremely detailed cuts.

oBest For: High-throughput textile operations where blade longevity and durability are critical, and machines support the 3.0mm thickness.

Summary

For precision and balanced durability, the 108065-S (6mm width, 2.5mm thickness) is excellent.

For heavier cutting with more stability, the 105935-25 (8mm width, 2.5mm thickness) offers a robust solution.

PREV : Tungsten carbide Circular Rotary Knife Blades For Sale Replace Compatible NEXT : Summa Drag And Tangential Knives For Summa Vinyl Cutters Price For Sale Official