Jwei Aol Iecho Ruizhou Aoke Ruk Sinajet Cutting Machine Maintenance Knowledge And Skills

The maintenance knowledge and skills for JWEI, AOL, Iecho, RuiZhou, AOKE, and RUK Sinajet cutting machines share common principles focused on ensuring machine longevity, cutting accuracy, and operational safety. Here is a comprehensive overview based on the available information:

General Maintenance Knowledge and Skills for Cutting Machines

1. Daily and Routine Cleaning

· Clean the machine surface, guide rails, cutting area, and drive systems daily to remove dust, debris, metal slag, and residues. This prevents wear and operational jams and maintains cutting accuracy.

· For plasma cutters and digital cutters, ensure the cutting head, optical paths, and torch components are free from dirt and metal particles.

2. Lubrication

· Regularly lubricate mechanical components such as guide rails, racks, gearboxes, and cutting gears to minimize friction and extend lifespan. Use the recommended lubricants (e.g., NO. 30 oil for slitting knives and pressure line wheels) and follow lubrication intervals based on usage (weekly or per shift).

· Oil-immersed lubrication systems should have oil changed after the first 300 hours and then as needed.

3. Inspection and Replacement of Wear Parts

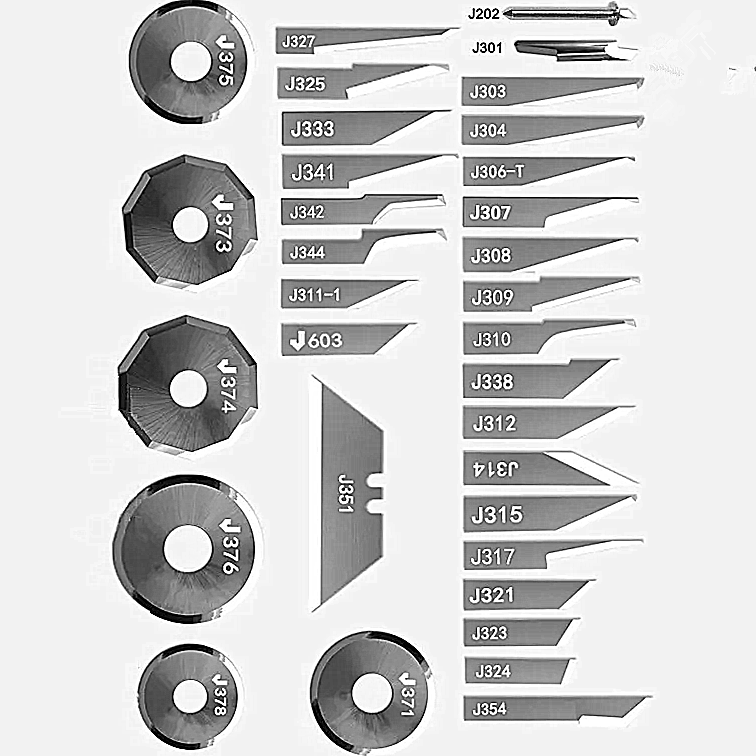

· Frequently inspect cutting tools, blades, nozzles, electrodes, and consumables for wear, burrs, or deformation. Replace or resharpen dull or damaged parts immediately to maintain cut quality and prevent damage to other components.

· Check pneumatic components for leaks daily and repair promptly.

· Inspect cables, clamps, sensors, and connections regularly to ensure safety and proper operation.

4. Calibration and Adjustment

· Perform initial setup, calibration, and test cuts when installing or after maintenance to ensure cutting precision. Adjust parameters and hardware as needed.

· Conduct daily computer corrective actions to ensure display values match mechanical indicators, maintaining cutting size accuracy.

5. Structural and Safety Checks

· Periodically check the machine’s structural frame for cracks, loosened bolts, and guide rail alignment. Reinforce supports if necessary to prevent vibration and deformation that affect cutting accuracy.

· Verify the functionality of safety shields, emergency stops, and safety switches regularly to prevent accidents.

· Follow strict safety protocols around sharp cutting knives and moving parts.

6. Preventive and Smart Maintenance

· Implement a preventive maintenance schedule based on operating hours and usage conditions to avoid unexpected failures.

· Use digital maintenance systems to monitor motor current, tool vibration, and temperature for predictive maintenance planning.

· Keep detailed maintenance logs for parts replacement and repairs to optimize future maintenance.

7. Staff Training

· Train operators and maintenance personnel on machine principles, correct operation, inspection routines, lubrication, troubleshooting, and emergency procedures to ensure proper maintenance and safe use.

Specific Tips for JWEI Digital Cutters and Clothing Template Cutting Machines

· Familiarize yourself with the user manual and safety labels before operation

· Regularly clean the clothing template cutting machine and guide rails daily, and ensure air sources and power are turned off after use.

· Maintain lubrication on rails and racks, and check for loose joints and cutting torches weekly.

· Regular maintenance on guide rails enhances cutting accuracy and prolongs machine life.

Summary Table of Key Maintenance Tasks

|

Maintenance Task |

Frequency |

Notes |

|

Cleaning machine surface & parts |

Daily |

Remove dust, debris, metal slag |

|

Lubrication of mechanical parts |

Weekly or per shift |

Use recommended oils; oil change after 300 hours |

|

Inspect and replace wear parts |

Daily to weekly |

Blades, nozzles, electrodes, pneumatic components |

|

Calibration and test cuts |

Initial setup, daily |

Ensure cutting accuracy |

|

Structural frame checks |

Quarterly |

Check for cracks, loosened bolts, alignment |

|

Safety checks (shields, switches) |

Daily to weekly |

Verify emergency stops and safety devices |

|

Digital monitoring & logs |

Continuous |

Predictive maintenance planning |

|

Staff training |

Regular |

Operation, maintenance, safety procedures |

This maintenance framework applies broadly to JWEI, AOL, Iecho, RuiZhou, AOKE, and RUK Sinajet cutting machines, supporting stable operation, precision cutting, and extended machine life.

PREV : Tips on Using Iecho Ruizhou Jwei AOL Ruk Sinajet Cutting Machines in Business NEXT : Where To Buy Customized Oem Atom Flashcut And Cnc Digital Replacement Cutter Knife Blades In China