1. What is the tungsten steel blade made of?

The blade is typically made of tungsten carbide, an alloy of tungsten and carbon, often combined with binders like cobalt or nickel to enhance toughness and reduce brittleness.

2. What are the main advantages of tungsten steel blades?

They have exceptional hardness (85–95 HRA), superior wear resistance (up to 600% better than standard steels), and maintain sharpness longer, resulting in cleaner, more precise cuts and less downtime due to fewer blade changes.

3. What applications are tungsten steel vibration knife blades suitable for?

They are ideal for cutting flexible materials such as leather, textiles, composites, plastics, corrugated cardboard, rubber, paper, foam, carbon fiber, and acrylic.

4. Which machines are compatible with tungsten steel vibration knife blades?

These blades fit various CNC vibration knife cutting machines including brands like ZUND, ATOM, Comelz, ESKO Kongsberg, IECHO, JWEI, RUIZHOU, AOKE, SINAJET, and RUK.

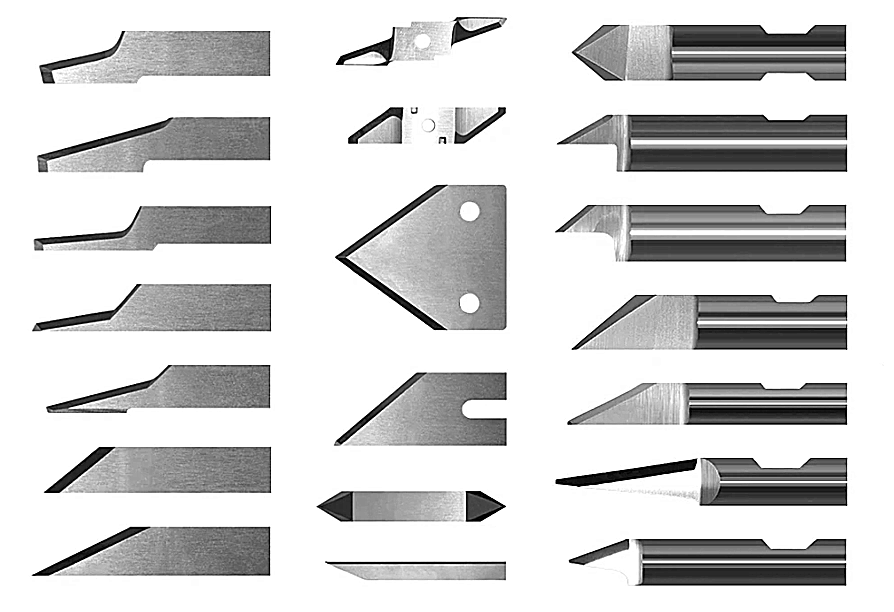

5. What are typical blade specifications?

Blades come in different sizes and angles, for example, lengths from 28mm to 85mm, widths around 5.5mm to 7mm, heights about 0.6mm to 1mm, and angles ranging from 6° to 45°, customizable per machine model.

6.How durable are tungsten steel blades?

Their durability is significantly higher than standard steel blades, offering up to 8-10 times longer tool life due to their hardness and wear resistance.

7. How do tungsten steel blades improve cutting performance?

They reduce friction, enable high-speed cutting, withstand high temperatures, and produce less waste at the start and end of cuts, improving overall productivity.

8. Are tungsten steel blades brittle?

Pure tungsten carbide is brittle, but the addition of binders like cobalt enhances toughness, balancing hardness with reduced brittleness.

9. What maintenance or handling considerations exist?

Proper handling to avoid impact damage is important; using appropriate cooling and lubrication during cutting extends blade life. Maintenance tips include regular inspection and cleaning to maintain performance.

10. Can tungsten steel blades be customized?

Yes, blades can be customized in size, shape, and angle to fit specific cutting machines and applications.

11. What industries benefit from tungsten steel vibration knife blades?

Packaging, aerospace, automotive, defense, textile, and composite manufacturing industries commonly use these blades for precise and durable cutting solutions.

12. How do tungsten steel blades compare to other materials?

Compared to high-speed steel and standard carbide blades, tungsten steel blades offer higher hardness, better heat resistance, longer tool life, but at a higher initial cost justified by performance gains.

These points provide a comprehensive understanding of tungsten steel blades used in vibration knife cutting machines, highlighting their material properties, applications, compatibility, and advantages in industrial cutting processes.

Shenzhen Oyea Global sales: ensuring availability across Europe, the USA, the Middle East, and Asia with efficient shipping and customer service.Sold To Germany, France, The United Kingdom, Poland, The United States, Russia, Vietnam, Thailand, Indonesia, Singapore, The Netherlands, Switzerland, South Korea, Japan, Turkey, The Philippines, Hong Kong, Taiwan, Italy, Spain, Hungary, The Czech Republic And Other Countries Or Regions

PREV : Colex T00505 Esko Kongsberg Bit-Mus06-4022-50 Zund R158 Router Bits Compatible And Equivalent NEXT : Messer Нож Scian Nóż Pisau Lama Lame Čepel Penge 잎 Lưỡi Dao Jwei/Jingwei Knife Blade