The top problems commonly encountered with ZUND, ATOM, Summa, and similar CNC cutting machine cutting system blades include the following:

1.Blade Dullness or Damage

Blades wear out or get damaged over time due to extensive use or improper handling, causing jagged edges and poor cutting quality. Regular inspection and timely replacement are necessary.

2.Inaccurate Cutting

Misalignment of media, incorrect blade offset settings (especially for drag knives), or improper cut settings in software can lead to inaccurate cuts and poor corner quality such as notched or rounded corners.

3.Blade Offset Issues (Drag Knives)

Incorrect blade offset compensation causes poor corner cuts—too high offset results in beveled corners, too low causes rounded corners. Proper offset calibration is critical for sharp, precise corners.

4.Cutting System Software Updates Causing Hardware Issues

Firmware or software updates (e.g., Summa cutter updates to increase speed) have been reported to cause hardware failures such as fried driver chips on the PCB.

5.Machine Size Limitations

Smaller cutting tables require multiple media advances for large sheets, increasing the risk of media skewing and imperfect joining cuts.

6.Expensive Tool Modules

Additional modules for holding multiple tools (e.g., for simultaneous cutting and creasing) can be costly, limiting operational flexibility.

7.Power and Connectivity Issues

Summa cutters sometimes fail to power on due to faulty power supplies or loose connections; software connectivity problems can also disrupt cutting operations.

8.Media Feeding Problems

Incorrect media feeding or roller misalignment causes uneven cuts and jagged edges. Regular roller alignment checks are necessary.

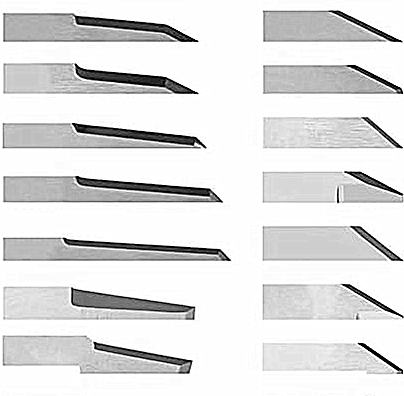

9.Blade Mounting and Compatibility

Using blades not specifically designed for the machine model can cause mounting instability, inconsistent rotation, and poor cutting quality.

10.Blade Change and Calibration Complexity

Blade replacement requires careful loosening, replacement, securing, and recalibration through software, which can be time-consuming and prone to error if not done properly.

11.Vacuum Table Maintenance

Debris on vacuum tables can affect media holding and cutting accuracy, requiring regular cleaning.

12.Wear on Carriage Rails

Lack of lubrication or maintenance on carriage rails can lead to mechanical issues affecting cutting precision.

13.Cutting Speed vs. Quality Trade-offs

Increasing cutting speed (e.g., via software updates) may stress hardware components and reduce cut quality or machine longevity.

14.Blade Type Mismatch

Using incorrect blade types for specific materials leads to poor cutting performance and blade damage.

15.Environmental Factors

Dust, humidity, and temperature fluctuations can impact blade performance and machine electronics, requiring controlled operating environments.

These issues are common across ZUND, ATOM, Esko Kongsberg,Summa, and similar CNC cutting systems and can be mitigated by proper maintenance, correct blade selection and calibration, and careful handling of software updates.

PREV : lame du couteau Esko Kongsberg Bld-Sr6303 est-elle plus efficace que celle du Bld-Sr6224? NEXT : Summa Messer für Schneideplotter 391-358 391-360 390-550 391-231 390-534