This ultimate guide provides a detailed exploration of CNC router oscillating knife blades, covering their various types, practical applications, and essential tips for selection and upkeep. Synthesized from cutting-edge industry knowledge and expert insights, it aims to help users make informed decisions regarding these tools. Brands like Zund, Summa, Roland, Atom, Gerber, Aristo, Esko, Iecho, and Jwei represent key players in the market, offering a wide range of CNC router oscillating knife blades suited for diverse needs and projects.

Understanding CNC Oscillating Knife Blades: Types, Benefits, and Selection Criteria

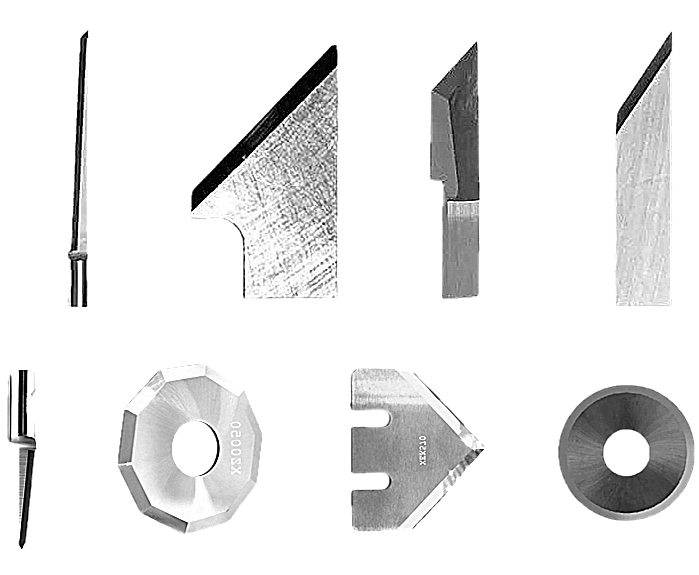

1. Exploring the Types of CNC Oscillating Knife Blades and Their Applications

- Standard Oscillating Knife Blade: This blade is designed for cutting soft to semi-rigid materials like rubber, leather, foam, and fabric with unmatched precision. Its slim profile and high-frequency oscillation enable clean cuts without causing frayed edges, making it ideal for delicate projects.

- Deep Cut Oscillating Knife: Featuring a longer blade, this option is tailored for working with thicker materials such as layered composites, dense foam, or carpets. It ensures deep and precise cuts without jeopardizing the blade’s stability, making it indispensable for high-thickness applications.

- Perforation Blades: Equipped with small cutouts along the edge, these blades create perforated lines rather than continuous cuts. They are perfect for applications requiring tear-away sections or fold lines in materials like paper, vinyl, and transparency films while minimizing tear-out and distortion.

- Tangential Knives: With full directional control, tangential knives excel at producing sharp corners and intricate curves. Often compatible with interchangeable cartridges—such as creasing wheels and angled blades—their versatility makes them ideal for diverse cutting and creasing tasks.

2. How Oscillating Knife Blades Operate and Why They Outperform Traditional Methods

Oscillating knife blades cut through materials by moving rapidly up and down in a "sawing" motion rather than relying on dragging. This efficient method significantly reduces friction and heat buildup, preventing deformation or fraying in softer or layered materials.

Industries such as packaging, textiles, signage, and composites benefit significantly from oscillating knives. Common materials like cardboard, EVA foam, leather, PVC, and rubber are handled effortlessly due to the blades' superior cutting performance.

3. Selecting the Right Oscillating Knife Blade for Your CNC Router

To maximize performance and precision when using CNC oscillating knife blades, consider these critical factors:

- Material Compatibility: Choose a blade type suited to your material’s properties. For instance, deep cut blades are better for thick foam or composites, while standard blades work well for softer, thinner materials.

- Blade Material and Coating: High-speed steel (HSS) offers durability and sharpness for general use. If your project involves abrasive materials, carbide or diamond-coated blades provide enhanced longevity but may demand a higher budget.

- Blade Size and Shape: Match the blade dimensions to your cut depth and design complexity. Longer blades allow deeper cuts but may require slower feed rates to maintain cutting accuracy.

- Machine Compatibility: Ensure the selected blade is compatible with your CNC router’s collet or blade holder system. Some blades offer universal compatibility while others are tailored for specific machines such as Zund, Summa, Roland, Atom, Gerber, Aristo, Esko, iEcho, Jwei, or other CNC routers.

4.Maintenance and Longevity Tips

- Regularly evaluate blade sharpness using standardized tests or cutting samples to ensure consistent cutting performance.

- Replace blades immediately when they become dull to prevent compromised cuts and potential damage to the material.

- Clean both blades and their holders frequently to eliminate material buildup that might obstruct cutting accuracy.

- Store blades securely to preserve their edges and minimize the risk of injury.

5.Advantages and Drawbacks of Oscillating Knife Blades

Advantages:

- Highly effective for cutting soft, flexible, or layered materials without causing fraying or tearing.

- The oscillating mechanism reduces strain on the material and minimizes blade wear, prolonging blade life.

- Adaptable blade types offer compatibility with diverse materials and cutting styles, including perforations.

- Delivers precise cuts with minimal distortion, making it ideal for detailed or intricate designs.

6.Additional Considerations

- Certain CNC oscillating knife machines come with integrated visual control systems and compatibility with popular design software like CorelDRAW and AutoCAD, streamlining precision and enhancing workflow efficiency.

- Optional accessories like brass guides and drag knife holders can increase cutting stability and improve control over blade movement.

- For projects involving abrasive or composite materials, pairing oscillating knives with tools such as rotary blades or creasing wheels can yield optimal results.

For those seeking compatible blade solutions, leading models such as Zund, Summa, Roland, Atom, Gerber, Aristo, Esko, Iecho, and Jwei CNC router oscillating knife blades are notable selections known for their quality and reliability across diverse applications. Shenzhen Oyea Machinery Co., Ltd further enriches this domain by offering innovative solutions and machinery designed to complement these blades, promoting efficiency and precision in modern manufacturing processes.

Global Sales:Ensuring Availability Across Europe, The America, The Middle East, And Asia With Efficient Shipping And Customer Service.Sold To Germany,France,United Kingdom,Poland,United States,Russia,Vietnam,Thailand,Indonesia,Singapore,Netherlands, Switzerland,South Korea,Japan,Turkey,Philippines,Hong Kong,Taiwan,Italy,Spain,Hungary,Australia,Malaysia,Canada, Czech Republic,Mexico,India And Other Countries Or Regions

PREV : Kongsberg Esko Bld-Df113 Bld-Df212 Bld-Df112 Bld-Df213 Bld-Rc110 Cutting Blades NEXT : How to select blade angle and thickness for iEcho BK/TK machines