|

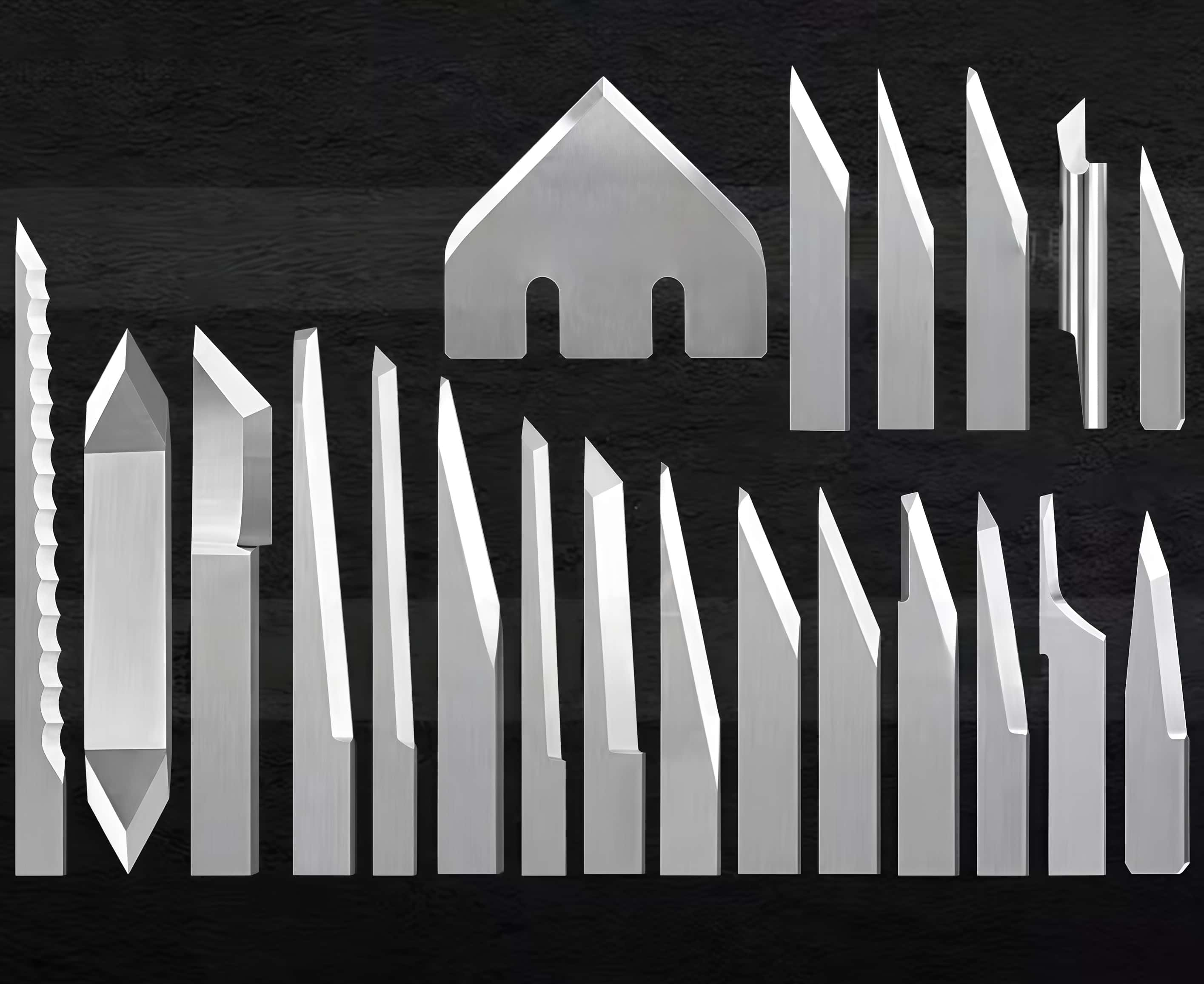

Blade Model |

Description / Typical Use |

Material Suitability |

Notable Features |

|

Basic cutting blades |

Light materials, thin films, paper |

Standard shapes for general use |

|

|

Medium and light materials |

Paper, thin PVC, reflective film |

Good for moderate precision cutting |

|

|

Flexible materials |

Textiles, leather, non-woven fabrics |

Excellent for soft, flexible materials |

|

|

Medium duty cutting |

Fabrics, composite material |

Versatile for various medium thickness |

|

|

Medium to thick materials |

Foam, carpet, honeycomb board |

Durable, thicker blade edges for heavy duty |

|

|

Specialized cutting needs |

Variety of composites |

High precision cutting |

|

|

Heavy duty, composite cutting |

Thick, tough materials |

High wear resistance |

Angle = material thinness + edge finish: shallow angles (≈30°) for thin/film materials and very fine detail; 45° is the general-purpose workhorse; steep angles (≥60°) for thick, dense or foam/corrugated where you need a stronger wedge.

Thickness / shank diameter = strength & depth: thicker blade bodies (larger cross-section, stiffer shank) for deeper cuts and hard materials; thin blades for fine, shallow work. iEcho oscillating/drag blades list body thicknesses (examples: 0.63 mm profiles and larger/tungsten-carbide types for heavy work).

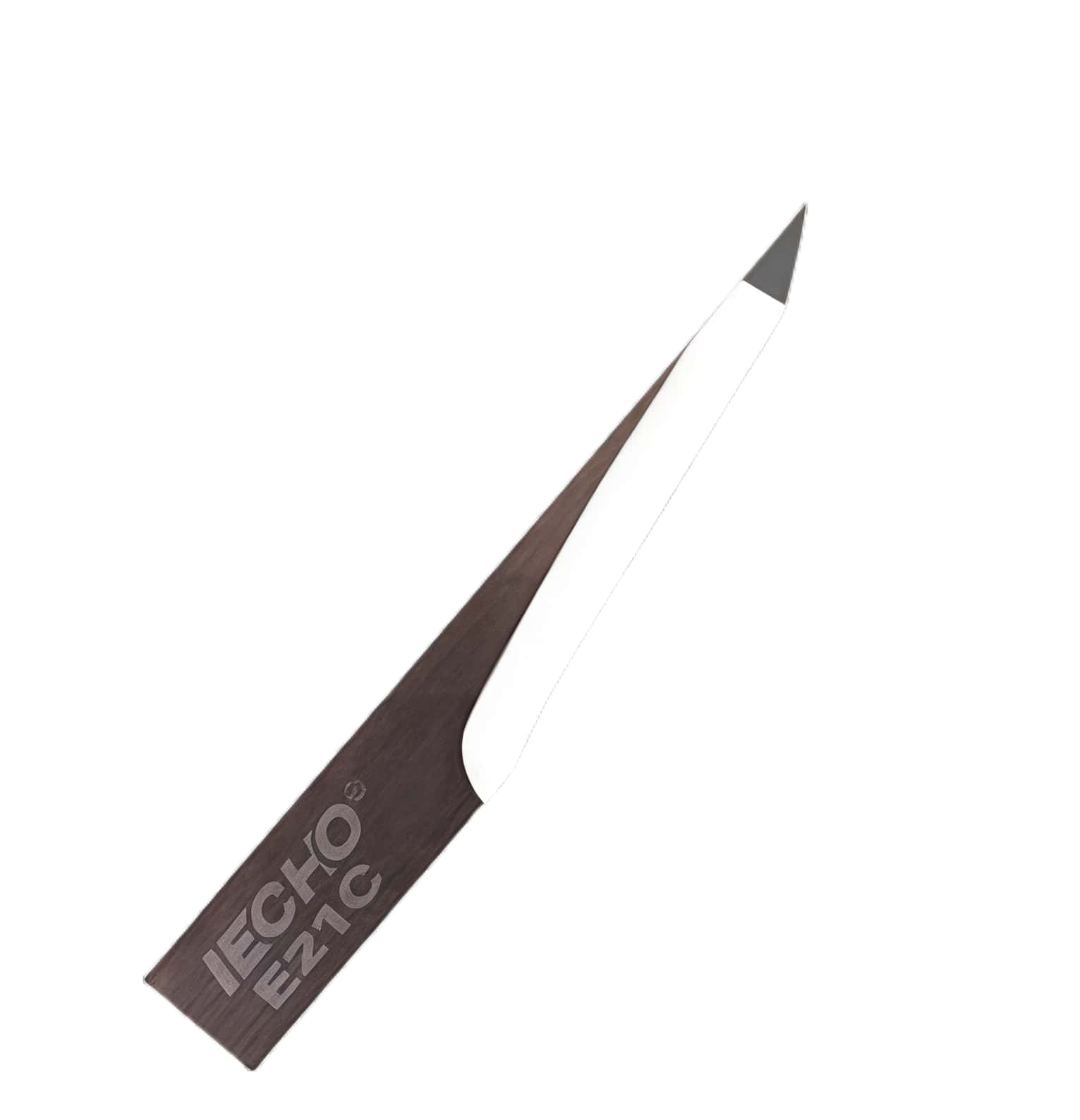

For iEcho BK and TK series cutting machines, blade angle and thickness selection depends primarily on the material type, thickness, and cutting precision requirements. iEcho BK and TK blades come in various models with differences in blade tip angle, thickness, shape, and material to suit different cutting needs. For example, blades like E16/E17, with moderate angles and thinner profiles, are suitable for medium and light materials such as paper, thin PVC, and reflective film. Thicker and more angled blades such as E64-5/E64-6 are recommended for medium to thick materials like foam, carpet, and honeycomb boards. Flexible materials like textiles, leather, and non-woven fabrics are best cut with blades E18L or E21, which are designed with angles and thicknesses optimized for softer materials.

Blade thickness affects rigidity: thinner blades (around 0.63mm) are for lighter, less dense material, while thicker blades (up to 1.5mm) provide more rigidity needed for denser or harder materials, preventing blade flex and improving cutting quality. Blade length should exceed the material thickness by at least 5mm to allow efficient cutting.

Blade angle selection ranges commonly from 0° to about 35° for oscillating knives, with lower angles ideal for intricate, thin materials requiring precision, and steeper angles for denser materials to reduce drag and wear. Adjust the blade length exposure on the machine manually along with pressure settings for optimal cutting performance.

In summary:

Choose blade model based on material type and thickness (e.g., E16/E17 for thin, E64-5/6 for thick).

Select blade angle ~ 16°–35° based on material density and desired cut precision.

Use blade thickness from 0.63mm (light materials) up to 1.5mm (dense materials) to ensure rigidity.

Ensure blade length exceeds material thickness by 5mm or more.

Adjust blade length and pressure on machine for cutting depth.

PREV : Tungsten Carbide Cnc Cutting Machine Knife Blade Manufacturer Wholesaler Distributor Suppliers NEXT : Between The Gerber Blade 21261011 And Other Gerber Blades