1. Blade Length:

The right blade length largely depends on the material thickness and cutting precision needed. Here’s a guide:

Short Blades (up to 45mm): Best for fine, intricate cuts on thinner materials (e.g., paper, vinyl, light cardboard).

Medium Blades (45mm–65mm): Suitable for regular materials like corrugated cardboard, foam, and standard plastics.

Long Blades (65mm and up): For cutting through thicker materials like dense foam, thick corrugated cardboard, and heavy plastics.

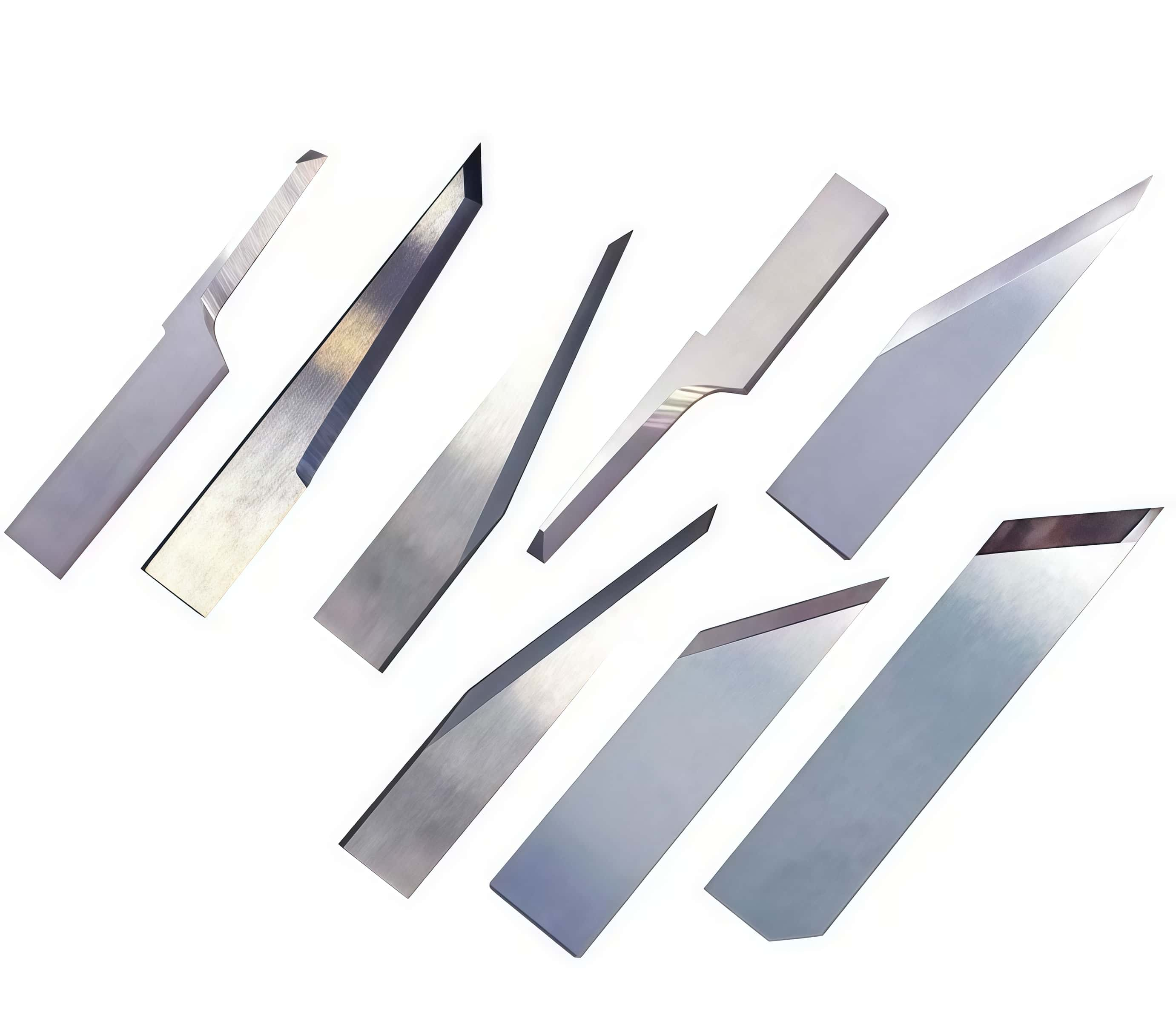

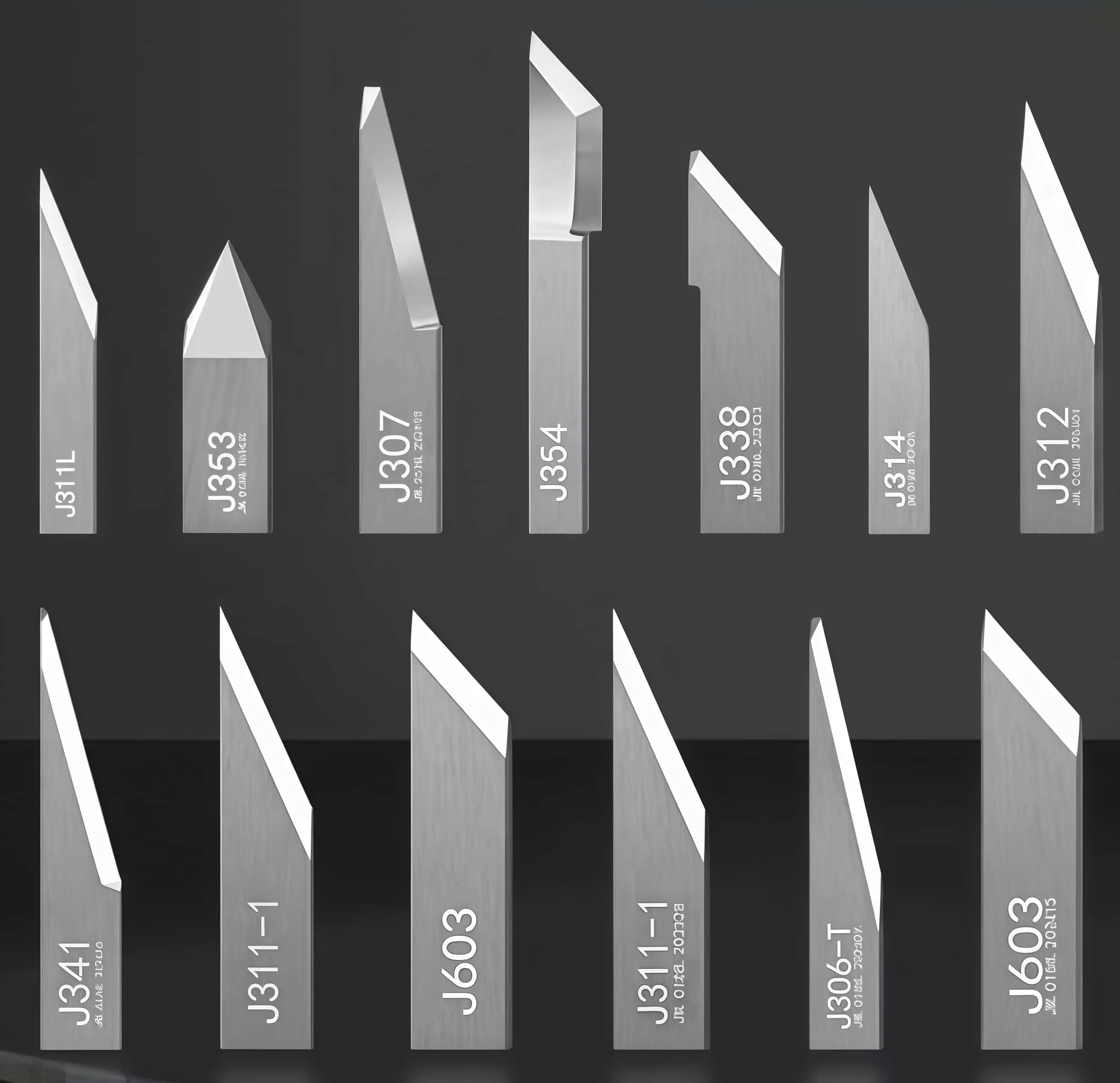

2. Blade Shape

Straight Blades: Ideal for precise, straight cuts on flexible or flat materials like paper, vinyl, or textiles.

Perforating Blades: Best if you need to create perforations for easy tearing. These are common for products like tickets or packaging.

V-Shaped Blades: Typically used for making beveled cuts on softer materials. These are great if you’re cutting thick card or foam and need an angled finish.

Rotary Blades: Ideal for cutting textiles or other soft materials that need smooth cuts with minimal fraying or stretching.

3. Blade Material:

Blade material affects durability, sharpness, and the kinds of materials you can cut.

High-Speed Steel (HSS): Ideal for cutting through cardboard, vinyl, and similar materials. HSS blades stay sharp longer but are more prone to chipping when cutting harder materials.

Carbide-Tipped Blades: These are harder and last longer, making them ideal for cutting through tough materials like composite boards, dense foam, or plastics.

Stainless Steel Blades: These are corrosion-resistant, so if you're cutting in a high-humidity environment or with wet materials, they could be a good option.

4. Specialized Blades:

If you're cutting through mixed materials, such as those that include both flexible and rigid sections, or if you need very fine precision for design work, you might want to look at blades that are coated with a special finish (e.g., Teflon-coated for anti-stick properties).

Recommendation Summary:

For general cutting needs with moderate material thickness: a medium-length straight blade (45–65mm) in high-speed steel.

For cutting thicker or more abrasive materials (like foam or composites): go for longer blades (65mm+) made from carbide-tipped steel.

For delicate, precise cuts on flexible materials, use a short blade (up to 45mm), potentially a otary or V-shaped blade.

PREV : Zund Multipurpose Router Zund Acm Router Zund Acrylic Aluminium Router Differences And Models NEXT : Zund R108 R141 R202 R203 R204 R208 R209 R503 router bits for zund