The ZUND ATOM CNC tungsten carbide cutting blades are engineered to deliver high precision, durability, and efficiency, particularly when dealing with challenging and heat-sensitive gasket materials such as rubber, graphite, non-asbestos sheets, and reinforced composites. These blades employ oscillating motion to mitigate heat generation during the cutting process, ensuring the preservation of material integrity by avoiding thermal damage like burning or melting. Available in diverse configurations, including straight-edge and hook-shaped designs, these blades are offered with varying thicknesses and drag angles tailored to accommodate the specific requirements of different gasket materials and cutting depths.

Notable examples of ZUND tungsten carbide blades optimized for gasket material processing include:

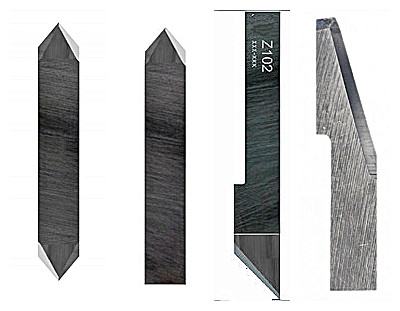

- Z102 Drag Knife Blade: Crafted from tungsten carbide, this blade is specifically designed for cutting lighter, softer materials. With a cutting angle of 45° and a maximum cutting depth of 7.8 mm, it combines a sharp edge with exceptional durability to maintain consistent performance. This blade corresponds to ZUND part number 5219049.

- Z10, Z11, Z12, Z13 Blade Series: These blades are highly versatile and engineered for achieving precise, clean cuts. Featuring calibrated drag angles, they excel in processing a broad range of materials, such as vinyl, foam, fabric, cardboard, and gasket substrates. Their compatibility with ZUND cutting systems enhances their utility in professional settings.

- ATOM Blade (Part Number 01030793): This blade is particularly effective for cutting stiff and rigid materials, including sole leather and various gasket types, such as asbestos-free sheets and tang graphite composites. Capable of handling thicknesses up to 10 mm, it is optimized for high-speed cutting tasks.

The tungsten carbide composition of these blades offers notable advantages including exceptional wear resistance, superior heat tolerance, and extended edge retention. These properties make them ideally suited for the demands of cutting intricate gasket shapes while ensuring high-quality edge finishes.

In conclusion, ZUND ATOM tungsten carbide blades are prominently utilized in gasket material applications due to their oscillating cutting mechanism, high precision, and robust durability. Blades such as the Z102 Drag Knife and the Z10-Z13 series are particularly recognized for their efficacy in handling heat-sensitive and abrasive materials. Additionally, the ATOM blade (part number 01030793) stands out for its ability to process thicker materials up to 10 mm efficiently, further demonstrating the versatility and performance expected from ZUND technologies.

Zund Atom CNC tungsten carbide blades are utilized in the cutting of gasket materials, serving applications in production, manufacturing, wholesale distribution, and sales. These blades are renowned for their origin, quality, and reliable supply, further supported by their competitive pricing and availability through factory outlets and retail stores. Shenzhen Oyea Machinery Co., Ltd. specializes in providing these precision products to meet industrial requirements.

PREV : My Zund S3 G3 Digital Cnc Cutter| Cutting System Consumables Accessories Spare Parts Webshop NEXT : Would A Tungsten Carbide Blade Be Used For Cutting And Harder Materials?