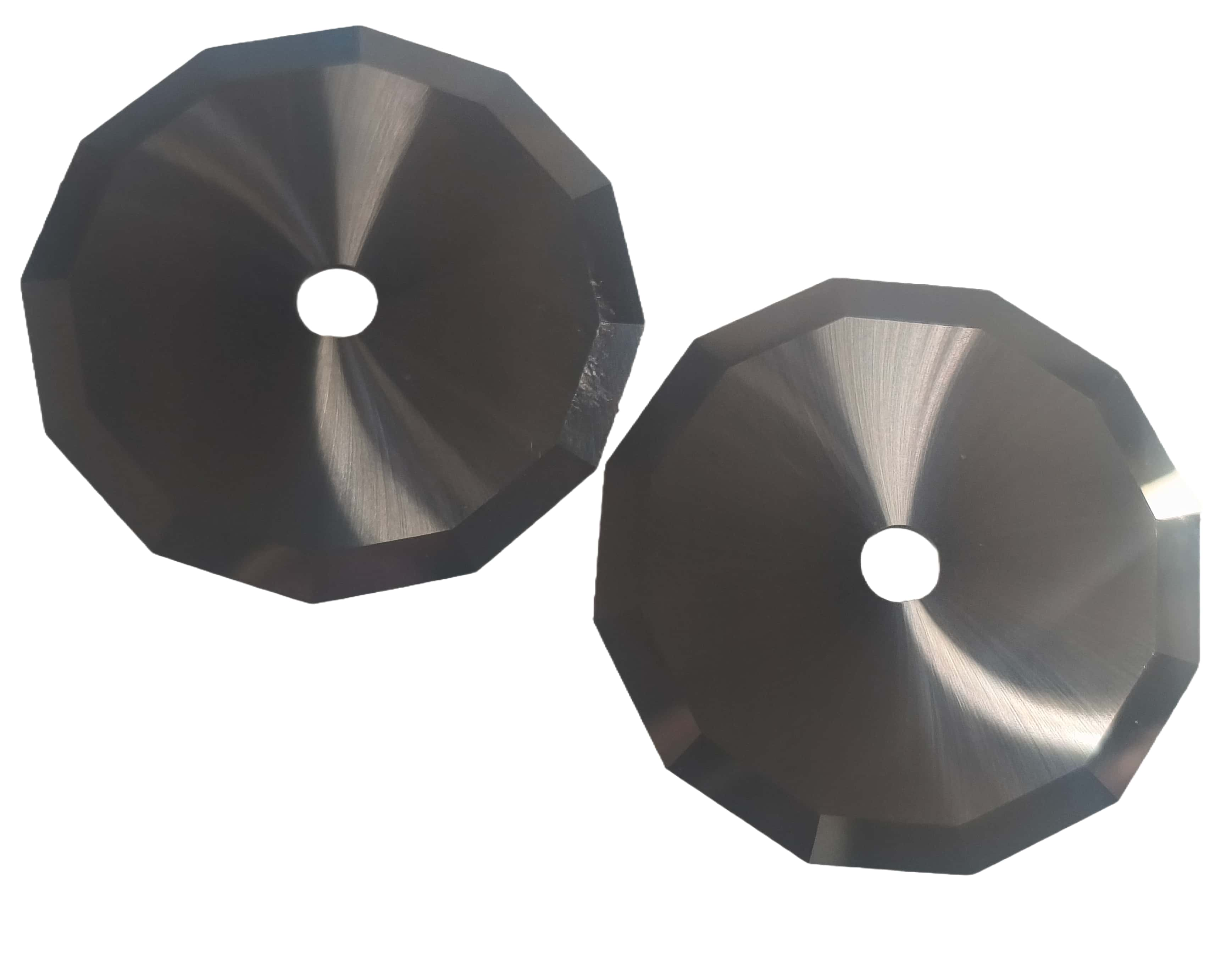

Tungsten carbide rotary cutter blades with 12 or 16 polygonal sides are precision industrial tools designed for long-lasting, accurate cutting of textiles, fabrics, and similar materials. These multi-sided blades allow users to rotate the blade to a fresh edge, extending usable life dramatically compared to single-edge rotary blades.

Key features and specifications:

Material: Tungsten carbide offers extreme durability and edge retention (known to last 50–100 times longer than steel or stainless steel alternatives).

Blade shape: Polygonal (typically 12- or 16-sided) circular/ring blades; each side functions as an individual cutting edge.

Applications: Designed for cutting fabric, leather, felt, non-woven textiles, carpet, shearling, and similar materials. Multi-edge design minimizes downtime for blade changes.

Sizes: Diameters in the 45mm–60mm range are common for fabric and textile use, though custom sizes and thicknesses are available depending on the machine and cut profile.

Sharpening and maintenance: Tungsten carbide blades hold their edge far longer than steel, but are somewhat brittle—impacts (such as dropping) may cause cracks or breaks, so they require careful handling.

Benefits:

Extend production intervals between blade replacements

Reduce fraying and distortion of sensitive fabrics

Consistent, precise cuts due to lasting sharpness

Drawbacks:

Higher initial cost than steel or ceramic blades

Not suitable for rough handling; can chip or break under sudden force

Customization options: Blades are available with custom diameters, thicknesses, and edge geometries for specialized textile machines. Suppliers offer full customization based on application needs and machine models.

Typical industrial users:

Garment factories

Textile and upholstery production

Carpet and soft materials processing

Top manufacturers and sources:

Products are available from Shenzhen Oyea Machinery Co., Ltd.. Standard and custom orders are possible depending on quantity and specification.

For applications requiring extremely long blade life and precise textile cuts, tungsten carbide multi-sided rotary blades are a premier solution where fewer blade changes and clean edges are priorities

Tungsten carbide rotary cutter blades with 12 and 16 sides, designed for precise textile and fabric cutting. These high-quality blades are geared towards production, manufacturing, wholesale, and sales, ensuring reliability and performance. Known for their durability, competitive pricing, and superior craftsmanship, they originate from Shenzhen Oyea Machinery Co., Ltd., which offers supply options along with OEM and ODM customization services tailored to meet diverse industry needs.

PREV : RUK RUKDP014 RUKDP015 RUKDP016 RUKDP017 RUKDP018 087 088 089 Driving Rotary Knife Blades NEXT : Circular Dished Slitter Knives Knife Blades Knives For Shear Cutting Machinery