Blade Material and Coating Type

- Titanium Nitride (TiN) coating is the most widely used, offering excellent wear resistance, increased surface hardness, reduced friction, and FDA approval for food contact. It is ideal for cutting plastic films, coated materials, and packaging substrates typical on these machines.

- Ceramic edge coatings are suited for abrasive materials containing calcium carbonate or titanium dioxide additives, extending blade life on coated and mineral-filled plastics.

- Zero-friction coatings are designed for high-speed cutting of clingy, elastic films and reduce drag, preventing heat buildup and achieving clean cuts.

- Full ceramic coatings protect the entire blade surface, useful for multilayer films and aggressive additives, enhancing tool life and cut quality.

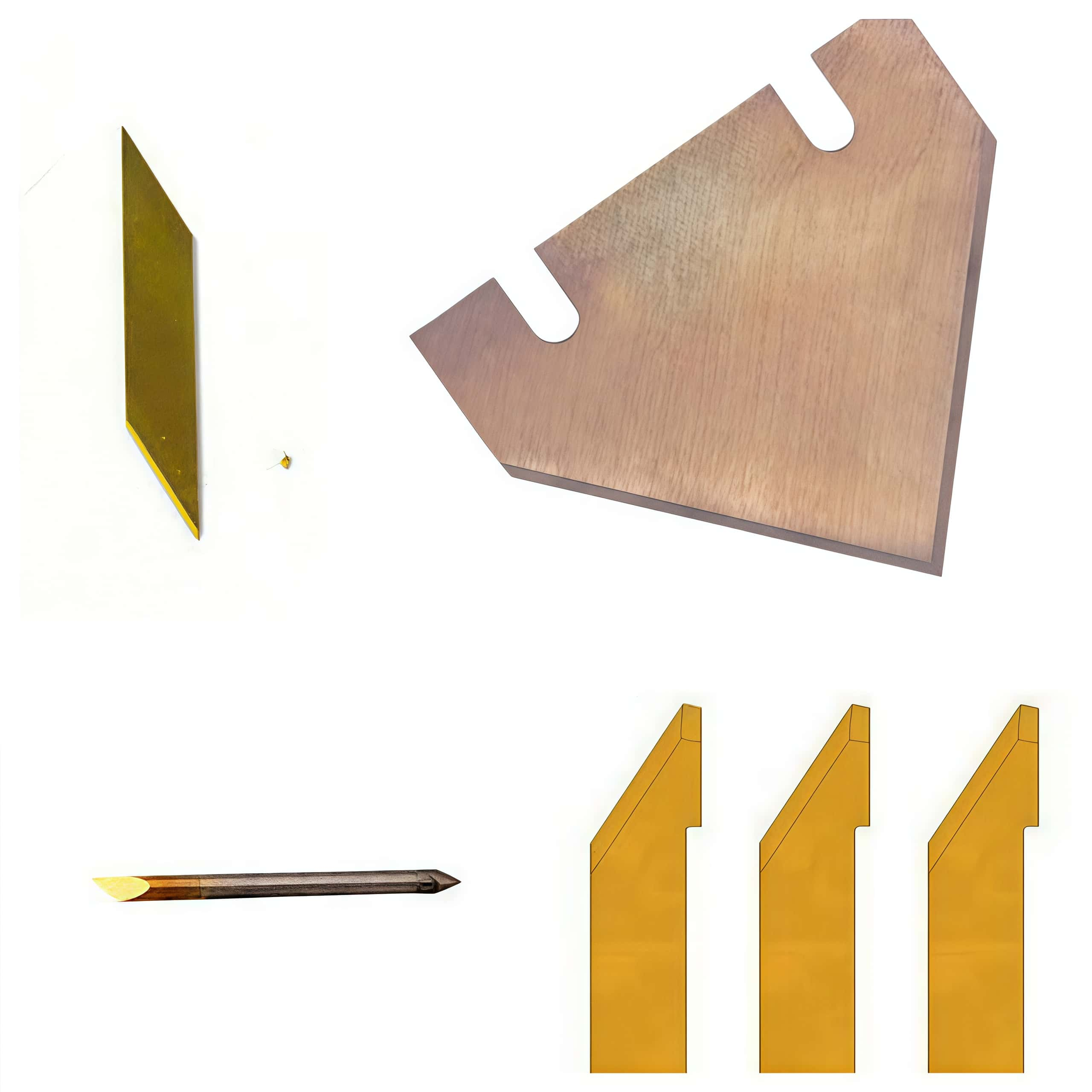

Blade Geometry and Angle

- Match blade angle to material type: 30° angle for thin, delicate films; 45° as an all-around angle; and 60° for thick or heavily coated substrates.

- Ensure the blade length adequately exceeds the material thickness by about 5mm to prevent wear on the blade base.

- Rigidity matters—thicker blades (e.g., 1.5mm) resist flexing especially on dense materials.

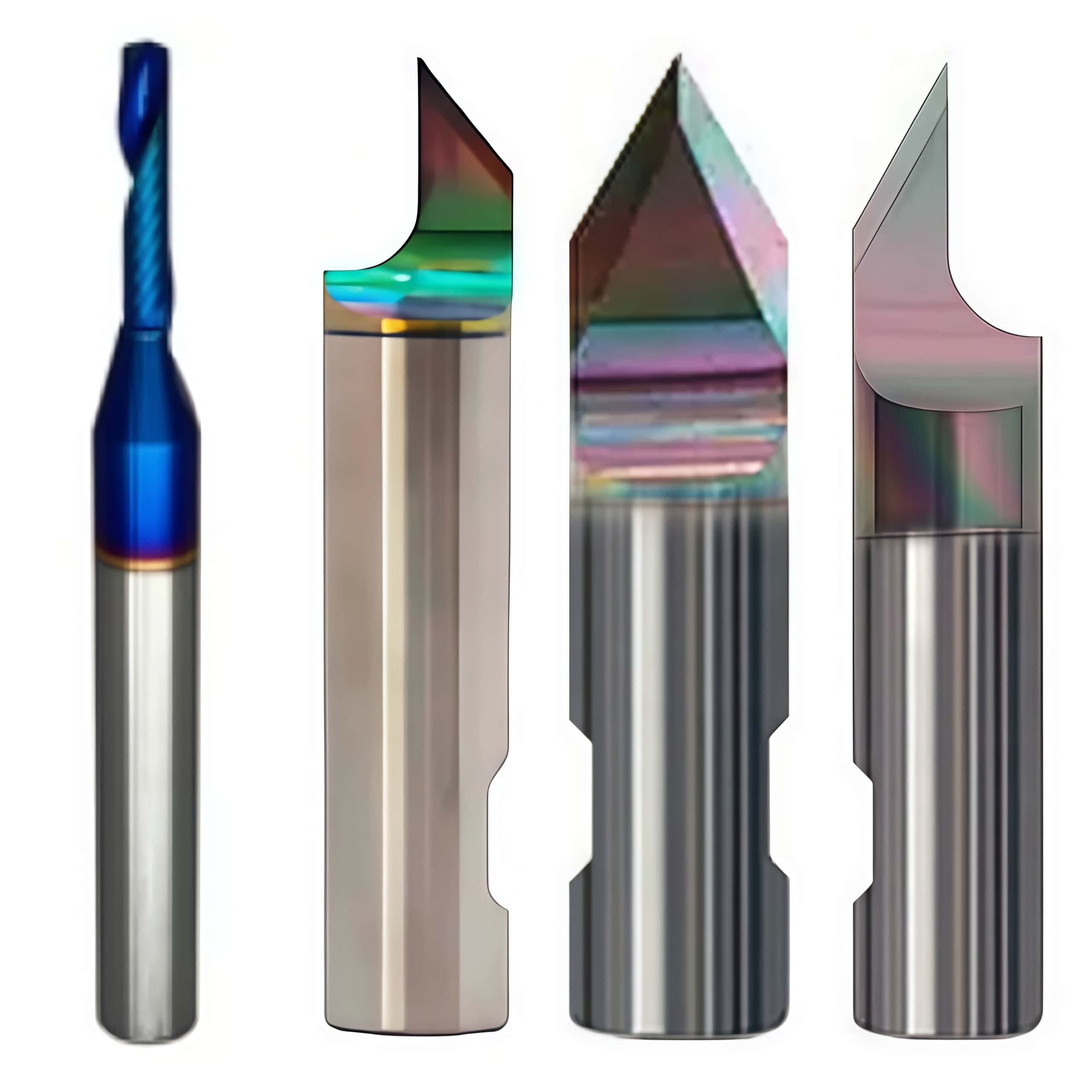

Machine Compatibility

- Verify blade shank diameter and style compatibility with the specific tool holder on the machine (Esko Kongsberg, Mimaki, Zund, or Summa), including whether the machine uses oscillating, drag/tangential, or router blade systems.

- Some machines and applications benefit from oscillating coated blades for clean cuts on coated foams or vinyls.

Application-Specific Considerations

- Coatings help reduce adhesive wear and friction residue buildup on coated or vinyl materials, improving cut cleanliness.

- Blade coatings also help dissipate heat during high-speed cuts, protecting the blade edge.

- Testing different coatings may be required to find the optimal balance for your material’s coating composition, thickness, and cutting speed.

Summary

Choosing the right coating knife blade involves:

- Selecting the appropriate coating for your material’s abrasiveness and adhesion properties.

- Choosing the right blade angle and geometry for substrate thickness.

- Confirming compatibility with your specific cutting machine system.

- Prioritizing coatings like TiN for general use, ceramic coatings for abrasive additives, and zero-friction coatings for sticky films.

Consulting with blade suppliers who offer coatings matched to your machine brand and specific substrate will help optimize blade life and cutting performanceCoating knife blades for Esko, Kongsberg, Mimaki, Zund, and Summa cutting machines function primarily as high-precision cutting tools designed for efficiently handling various materials through digital cutting systems. These blades have a coating that enhances durability, cutting accuracy, and resistance to wear, enabling smoother, burr-free edges especially when cutting materials like vinyl, foam, cardboard, textiles, and other flexible or composite materials.

Function and Use of Coating Knife Blades

- These blades, often drag or rotary knives, are designed to "drag" or rotate through the material for precise cuts, especially in complex curves or detailed designs.

- The coating on these blades improves the cutting edge’s sharpness retention, reduces friction, and resists corrosion, significantly extending blade life in high-volume production.

- They are used for cutting thin films, vinyl, reflective sheeting, cardboard, soft foams, textiles, and industrial fabrics across the different brand machines.

- Coated blades come in various angles (commonly 30°, 45°, 60°) suited to different material thicknesses and hardness, allowing optimal cutting performance without damaging the base material or backing layers.

Compatibility and Specific Machine Use

- Esko Kongsberg machines typically use coated drag or rotary blades with features like quick-release holders and auto-depth adjustment for tool calibration.

- Zund machines use coated blades in modular tools (Universal Cutting Tool, Kiss-cut Tool, Oscillating Tool) offering fast blade swaps and specific blade designs for different materials with enhanced durability.

- Summa cutters employ coated blades in their drag knife series and modules, optimized for high-precision cutting requirements, similar in design philosophy to Zund and Esko.

- Mimaki also uses coated cutting blades compatible with flatbed and roll-to-roll cutters, focusing on detailed cutting for signage, textile, and graphic applications.

Advantages of Coated Blades

- Improved cutting quality and edge finish.

- Extended blade life due to reduced wear.

- Better performance on abrasive or sticky materials.

- Reduced need for frequent blade changes, increasing productivity.

In summary, coating knife blades on these leading flatbed and digital cutting machines serve as durable, precise cutting tools that enhance machine performance across diverse material types, crucial for industrial and graphic production environments.

PREV : Colex T00505 Esko Kongsberg Bit-Mus06-4022-50 Zund R158 Router Bits Compatible And Equivalent NEXT : Messer Нож Scian Nóż Pisau Lama Lame Čepel Penge 잎 Lưỡi Dao Jwei/Jingwei Knife Blade