Know what each blade is for

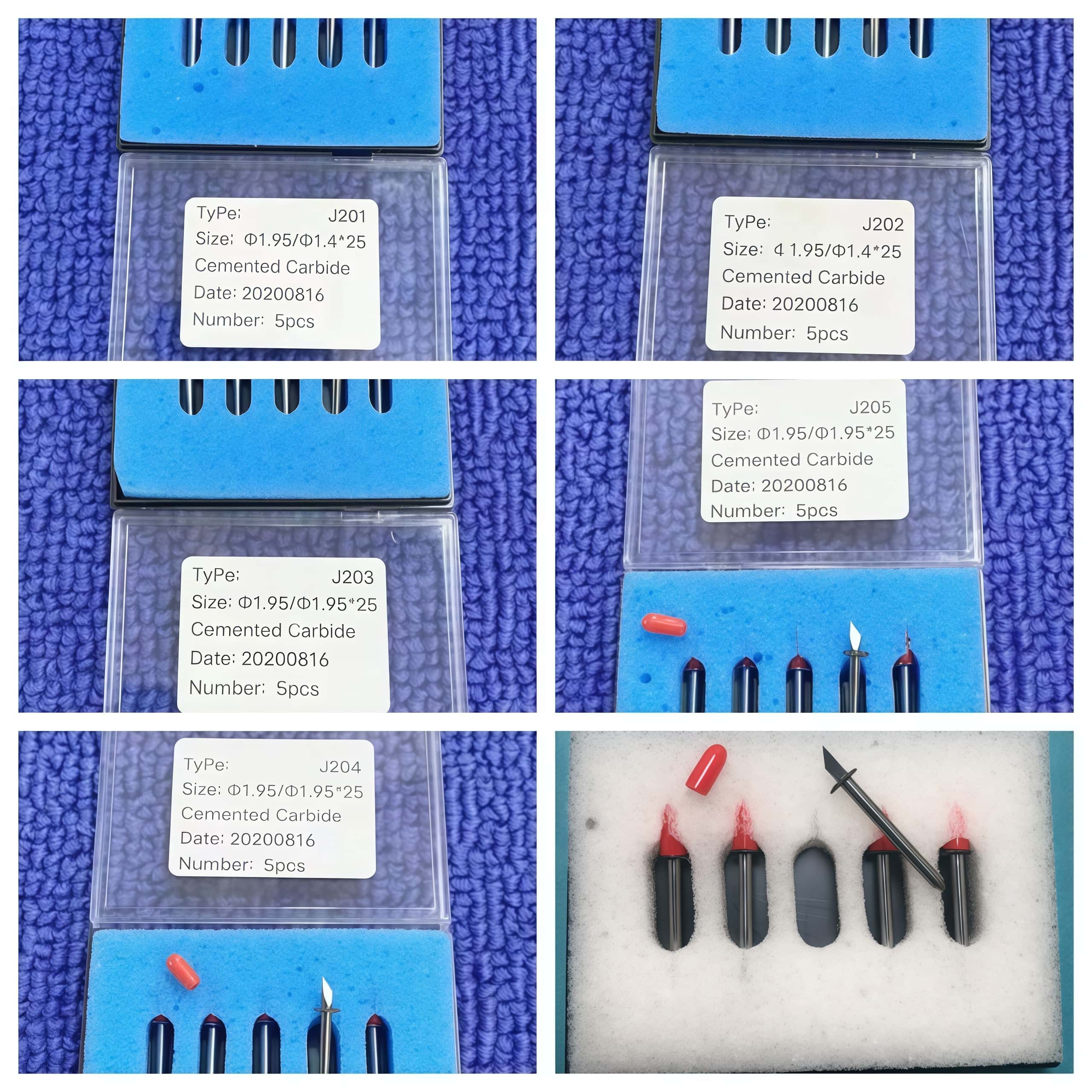

JWEI J201–J208 are round‑stock drag blades with different angles, heights, and max depths, while J301 is a thicker round‑stock knife mainly for standard oscillating/drag cutting of denser materials.

Typical specs (confirm against your supplier’s sheet or packaging): J201/J203/J204/J205 have 25 mm height with various angles and max depths from about 0.7–1.3 mm, J206/J208/J301 have 19 mm height with thinner or thicker bodies and max depths around 0.3–1.0 mm.

Typical usage focus

-

J201/J203 (30°) – thin films, paper, light card where low drag and long life are important.

-

J202/J204/J205/J206/J208 (45–60°) – self‑adhesive vinyl, labels, standard cardstocks and thin plastic sheets.

-

J301 (thicker, 50°) – somewhat thicker or denser substrates where a more rigid knife body helps tracking.

Installing the blade in the JWEI holder

-

Clean and inspect the holder: Remove the holder from the tool head, blow out dust, and verify the internal bore and clamping screw are clean so the round shank can rotate freely.

-

Insert the blade: Slide the J201/J202/J203/J204/J205/J206/J208/J301 into the correct JWEI drag‑knife holder (e.g., 01.49.2008 / 01.49.2009 / 03.22.0029 depending on your machine) until the shoulder seats and the round shank still spins freely.

-

Set initial protrusion by hand:

-

For kiss‑cut vinyl and labels with J202/J204/J206/J208, let the tip protrude roughly 0.1–0.2 mm beyond the material thickness, never exceeding the blade’s rated max cutting depth.

-

For through‑cut work with J201/J203/J205/J301, start with protrusion close to but below their specified max depth (for example 0.8–1.0 mm if the blade allows up to about 1.2–1.3 mm).

-

-

Tighten the clamp: Lock the set screw or collar using only firm hand pressure so the blade can still freely swivel during cutting but cannot move axially.

Adjusting depth and force on the machine

JWEI tables support automatic or semi‑automatic blade depth calibration plus test cuts; use these instead of guessing.

-

Run “Start Blade Calibration” (or equivalent) for the active tool to let the controller learn the current tip height relative to the table.

-

Perform a small test pattern on scrap of the same material:

-

For kiss‑cut (adhesive vinyl, stickers): The top layer should be cut cleanly and weed easily while the liner has only a faint scratch. If the liner is cut deeply, reduce either blade protrusion or cutting force; if the decal does not weed, slightly increase force first, then protrusion if needed.

-

For through‑cut: Edges should be clean with no heavy burring on the back; if you see over‑cut corners or fuzzy backing, reduce depth or force slightly, or slow the cutting speed for steep‑angle knives.

-

-

Choose the blade model based on substrate thickness and detail level using the table above.

-

Mount it in the proper JWEI holder, set conservative protrusion below the spec max depth, and ensure free swivel.

-

Run blade calibration, then do small test cuts to perfect depth and force for each material/preset, saving separate recipes for vinyl, paperboard, corrugated, etc.

PREV : Colex T00558 T00500 T00502 T00530 Router Bits Specifications NEXT : Cemented Carbide Blades for Mimaki Vinyl Cutter Cutting Plotter