Tungsten Carbide Cutting Knife Blades(TC Knife Blade) - China Manufacturers, Suppliers, Factory

Tungsten Carbide Blades Manufacturing Overview

If you're interested in the production process, here's a simplified outline:

-

Raw Materials Preparation

-

Tungsten powder (W) is mixed with carbon black to form tungsten carbide (WC).

-

A binder metal, typically cobalt (Co), is added to hold the carbide grains together.

-

-

Mixing and Milling

-

Powders are ball-milled with a binding agent and drying additives.

-

This forms a homogenous powder mixture.

-

-

Pressing/Forming

-

The powder is compacted into a “green compact” using cold pressing (or extrusion for some shapes).

-

Isostatic pressing may also be used for uniform density.

-

-

Pre-Sintering

-

Light heating removes binders and increases strength without full densification.

-

-

Sintering

-

The compact is sintered at 1,400–1,600°C in a vacuum or controlled atmosphere.

-

This creates a dense, hard carbide structure.

-

-

Finishing

-

Grinding, EDM (electrical discharge machining), and sometimes coating (e.g., TiN, TiAlN) for sharper, wear-resistant edges.

-

By Application:

Industrial Cutting Blades,Used in converting, packaging, printing, and textile industries.,Woodworking Blades,Circular saws, router bits, planer knives,Metal Cutting Blades

For steel, aluminum, and other metals,Plastic & Rubber Cutting Blades,Granulator and shredder blades,Food Processing Blades,Clean, sanitary cuts in frozen or fresh products,Paper & Pulp Blades,Slitter and guillotine blades.

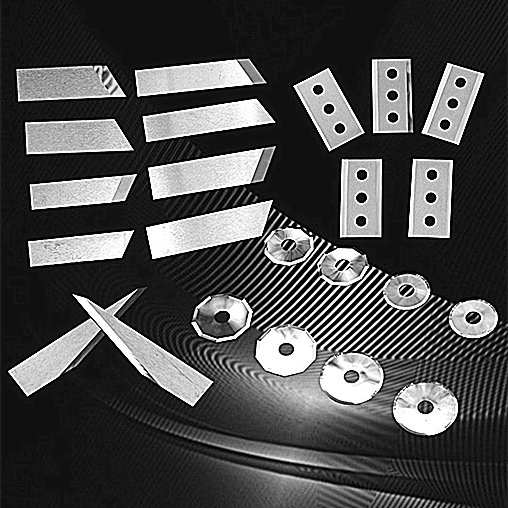

By Blade Type:Circular Blades,Straight Blades,Toothed Blades,Serrated Blades,Rotary Blades,Knives & Inserts

By Coating or Treatment:Uncoated Tungsten Carbide,Titanium Coated,Ceramic Coated,Diamond Coated (PCD Tips)

By Industry;Automotive,Aerospace,Packaging,Textiles,Medical,Construction

Key Features

Extreme Hardness: Second only to diamond.

Long Service Life: Retains edge sharpness longer than steel.

Heat Resistance: Ideal for high-speed cutting.

Precision Cutting: Clean, consistent cuts with minimal burring.

Corrosion Resistance: Withstands exposure to moisture and chemicals.

Customization Options:Blade diameter, thickness, and bore,Edge geometry (flat, beveled, serrated),Surface coatings for extended performance,OEM/ODM manufacturing support

Specialized in manufacturing the following blades:

Zund / Wild

Esko / Kongsberg

Martor

Aristo

Axyz

Bullmer

Summa

EcoCam

iEcho

Atom

Elcede

Sinajet

Stepcraft

Elitron

Comelz

MultiCam

JWEI

Colex

etc.

Shenzhen Oyea Global sales: ensuring availability across Europe, the USA, the Middle East, and Asia with efficient shipping and customer service.Sold To Germany, France, The United Kingdom, Poland, The United States, Russia, Vietnam, Thailand, Indonesia, Singapore, The Netherlands, Switzerland, South Korea, Japan, Turkey, The Philippines, Hong Kong, Taiwan, Italy, Spain, Hungary, The Czech Republic And Other Countries Or Regions

PREV : Ножи (Лезвия) для режущих плоттеров Iecho JWei RuiZhou NEXT : Esko Kongsberg Zund Bullmer Premiumcut Lectra Carbide Blades Pvd Coatings