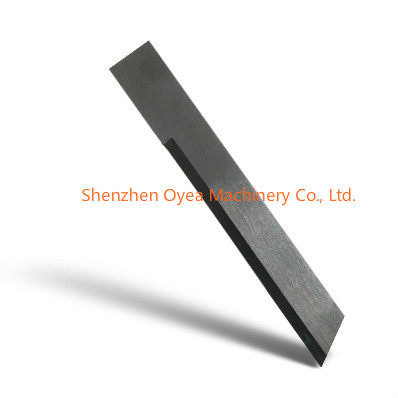

What Are The Advantages Of Using A Carbide Blade For The Zund Z71 Iecho E71 Bullmer B71 Multicam K71 Knife

The advantages of using a carbide blade for the Zund Z71, iEcho E71, Bullmer B71, and Multicam K71 knives include:

High Durability and Long Life: Tungsten carbide blades have a significantly higher life expectancy compared to high-speed steel blades, reducing the frequency of blade changes and downtime in production.

Precision V-Cutting: These blades are designed specifically for V-cutting applications, producing precise angled cuts, bevels, chamfers, and grooves with clean, accurate edges essential for corrugated cardboard, foam board, and similar materials.

Versatility Across Materials: Carbide blades effectively cut a variety of industrial materials such as corrugated cardboard, corrugated plastic, foam board, and composite panels, making them adaptable for diverse cutting tasks.

Reduced Tool Wear and Maintenance: The hardness and wear resistance of carbide minimize blade wear and damage during cutting, leading to lower maintenance costs and improved productivity.

Compatibility with Digital Cutting Systems: These blades are optimized for use in advanced digital cutting machines like Zund G3/S3, iEcho, Summa, Bullmer, and Multicam, ensuring seamless integration and consistent cutting performance.

In summary, carbide blades for these knife models offer enhanced durability, precise cutting capability, material versatility, and operational efficiency, making them ideal for industrial digital cutting applications requiring V-cuts and bevels.

Comagrav E71 V-cut Knife bladeKeyword:k71

Shenzhen Oyea Global sales: ensuring availability across Europe, the USA, the Middle East, and Asia with efficient shipping and customer service.Sold To Germany, France, The United Kingdom, Poland, The United States, Russia, Vietnam, Thailand, Indonesia, Singapore, The Netherlands, Switzerland, South Korea, Japan, Turkey, The Philippines, Hong Kong, Taiwan, Italy, Spain, Hungary, The Czech Republic And Other Countries Or Regions

PREV : Summa Aristo Gerber Esko Roland Zund Knives And CNC Knife Blades Are Widely Sold And Distributed NEXT : Atom Kimla Polska Grupa Cnc Seron Tungsten Steel Blade Compatibility Replacement Applicable