1. Shank Size Compatibility

Ensure the router bit shank matches the collet size of your Zund spindle. Zund cutters typically use a 6mm shank diameter for their router bits, so select bits with a 6mm shank to guarantee proper fit and stability.

2. Material to be Cut

Select bits optimized for the specific materials you work with:

- For softer materials like MDF, Forex, wood, Dibond, and plastics, use bits designed for soft materials (e.g., Zund R112, R113, R114).

- For harder materials such as acrylic and aluminum, choose bits made for hard materials (e.g., Zund R102, R103, R104).

- Specialized coatings like zirconium nitride (ZrN) or diamond-like carbon (DLC) can improve cutting performance and tool life on composites and metals.

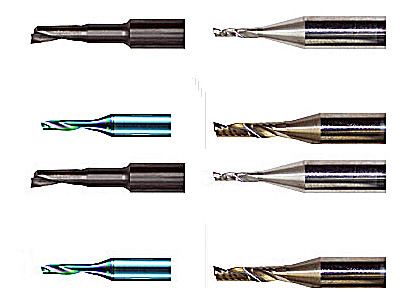

3. Bit Profile and Diameter for Project Detail

- Smaller diameter bits allow finer detail but cut slower and are more fragile.

- Larger diameter bits cut faster and provide smoother finishes but are less detailed.

- For detailed engraving or text, use V-groove or engraving bits.

- For general cutting, single or double flute spiral bits are common.

- Choose the shortest cutting length possible to reduce vibration and improve finish.

4. Bit Material and Coating

- Solid carbide bits offer durability and wear resistance, ideal for CNC routing.

- Carbide-tipped bits hold edges longer than high-speed steel but require careful handling.

- Coatings (e.g., Spektra, ZrN, DLC) enhance bit life and reduce heat buildup.

5. Project Requirements and Bit Sets

- Consider the level of detail and complexity of your project.

- Buying bits in sets can be cost-effective and provide versatility for different tasks.

6. Use Zund-Specific or Equivalent Bits

- Using Zünd original or certified replacement bits (like those from Shenzhen Oyea Machinery Co., Ltd) ensures optimal compatibility and performance.

- Examples include Zund bits R202-R209 and R503 or their equivalents with matching diameters and flute designs.

Summary

To pick the right router bit for your Zund CNC cutter:

- Confirm 6mm shank size for your collet.

- Match the bit type and coating to your material (soft vs. hard).

- Choose bit diameter and profile based on detail and cut speed needs.

- Prefer solid carbide or carbide-tipped bits with suitable coatings.

- Consider sets for versatility and cost savings.

- Use Zund original or high-quality equivalent bits for best results. Can be purchased from Shenzhen Oyea Machinery Co., Ltd

This approach ensures precision, durability, and optimal cutting quality on your Zund CNC digital cutter.)

PREV : Summa Aristo Gerber Esko Roland Zund Knives And CNC Knife Blades Are Widely Sold And Distributed NEXT : Atom Kimla Polska Grupa Cnc Seron Tungsten Steel Blade Compatibility Replacement Applicable