Zund CNC Cutting Knife Blade For Zund Digital Cutter Cutting Systems Flatbed Cutter

For selecting Zund CNC cutting knife blades tailored to Zund digital cutter flatbed cutting systems, there are specialized options designed to match various cutting needs, materials, and blade types that ensure precision, durability, and compatibility.

Recommended Zund CNC Cutting Knife Blades for Zund Digital Cutters:

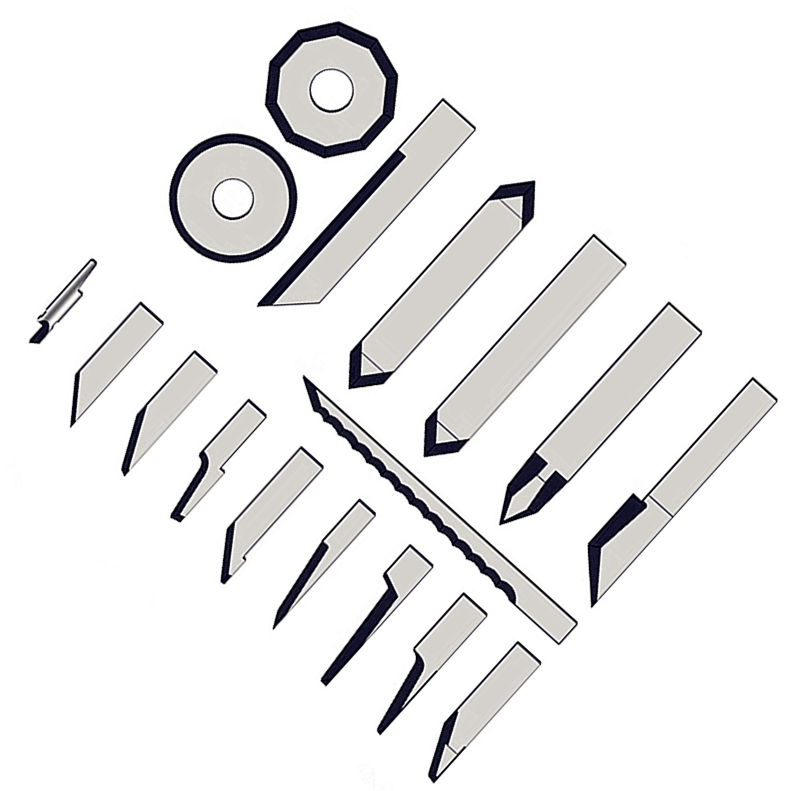

1. Zund Drag Blades (e.g., Z11, Z13)

o Why: Drag blades like Z11 and Z13 are robust tungsten carbide single or double-headed blades designed for flat material cutting, such as cardboard, textiles, and plastics.

o Differentiator: Excellent for simple through-cuts and kiss cuts on flat, moderately thick materials.

o Advantages: Durable, precise for standard materials; typically lower complexity.

2. Zund Oscillating Blades (e.g., Z16, Z20, Z21, Z602, Z23, Z26, Z29)

o Why: Oscillating blades move rapidly to cut thick, tough, or multi-layered materials like foam, sandwich boards, rubber, leather, and composites.

o Differentiator: Exceptional cutting depth and versatility; the Z602, for instance, offers a large max cutting depth (~111 mm) and premium tungsten carbide construction, perfect for heavy-duty applications.

o Advantages: Can handle complex materials and thick substrates with minimal wear; high precision.

3. OYEA Tools Replacement Blades

o Why: These blades are designed specifically as direct replacements for various Zund blade models, combining quality and cost-effectiveness.

o Differentiator: Equal or sometimes improved performance over OEM blades; many compatible variants to suit specific Zund models.

o Advantages: Reliable performance, good balance of quality and price, easy to source.

4. High-Quality Tungsten Carbide Oscillating Blades

o Why: Blades with solid tungsten carbide construction, such as the Z201 equivalent with a 17.4 mm cutting depth or the more heavy-duty Z602, deliver extreme durability and are suited for specialized cuts in materials like sandwich boards and foam.

o Differentiator: Precision engineered to match OEM specs, ensuring seamless integration and long life.

o Advantages: Durability and cutting efficiency reduce blade change frequency, enhancing productivity.

5. Rotary Blades (e.g., Zund Z51, Z53)

o Why: Rotary blades like Z51 and Z53 are designed for specific materials such as textiles, composite fabrics, and films, providing decagonal or circular cutting edges for smooth cutting.

o Differentiator: Ideal for graphic materials and fabrics, rotary blades minimize material distortion.

o Advantages: Smooth, clean cuts on flexible materials; long lifespan.

Summary

For achieving peak performance with your Zund digital cutter, it’s crucial to select the appropriate blade type based on your regular materials and desired cutting depth. Oscillating blades stand out for their versatility and resilience, making them ideal for thicker and more challenging substrates. On the other hand, drag blades excel in efficiency when working with thinner and flatter materials. High-quality replacement blades from reputable third-party providers can offer excellent value alongside comparable functionality. Rotary blades are specialized for applications like textiles and graphics. All recommended blades are crafted from premium tungsten carbide, ensuring precision and extended durability, specifically designed for Zund CNC flatbed cutting systems, such as those provided by Shenzhen Oyea Machinery Co., Ltd.

In this market, Shenzhen Oyea Machinery Co., Ltd. stands out as a reliable source for premium blade solutions. OYEA Knives offers a comprehensive range of both standard and custom leather-cutting knives and blades. Every standard product is manufactured to not only meet but exceed stringent OEM specifications, ensuring exceptional performance and durability. Moreover, their efficient shipping and dedicated customer service have enabled widespread availability across major global regions, including Europe, the Americas, the Middle East, and Asia.

Products from OYEA Knives have reached countries such as Germany, France, the United Kingdom, Poland, the United States, Russia, Vietnam, Thailand, Indonesia, Singapore, the Netherlands, Switzerland, South Korea, Japan, Turkey, the Philippines, Hong Kong, Taiwan, Italy, Spain, Hungary, Australia, Malaysia, Canada, the Czech Republic, Mexico, India, and many other global locations. With a firm commitment to providing top-notch products and service tailored to diverse regional demands, Oyea Machinery has established itself as a trusted partner in supplying precision blade solutions worldwide.

PREV : Zund Esko Colex Cnc Cutter Router Bit List Of Equivalents NEXT : Atom Aristo Zund Summa Iecho Cnc Router Knife Blades Differ In Wear Resistance And Sharpness