Maintaining and replacing tools for brands like ZUND, ATOM, COMELZ, Esko, ELITRON, and TESEO requires careful consideration to ensure optimal performance and longevity. Key points for each brand are outlined below:

ZUND

- Power up the machine appropriately and identify tools for each module.

- Replace knives with precision, aligning the drag knife point correctly and avoiding excessive tightening.

- Clean blade holders regularly and inspect for wear, applying grease where necessary for smooth functioning.

- Monitor blade guide wear indicators and replace tools promptly when significant wear is detected.

- Adjust vacuum power to suit operational needs.

- Conduct regular cleaning and inspections of tool mechanisms to prevent damage and maintain peak efficiency.

ATOM

- Carry out routine maintenance such as cleaning traveling head slides.

- Inspect and adjust chain pull monthly with the correct torque to avoid gear damage.

- Rotate and level the cutting board weekly and the aluminum alloy plate quarterly to prevent uneven wear.

- Replace hydraulic oil and filters every 8,000 working hours.

- Adhere strictly to safety protocols during any maintenance activities.

COMELZ

- Place the machine in a safe location away from fire or explosion hazards, sheltered from adverse weather conditions.

- Clean, inspect, and ensure the machine is leveled during maintenance.

- Use appropriate lubricating oil and maintain oil levels consistently.

- Replace knives by dismantling the guide and knife assembly, installing replacements properly thereafter.

- Clean external mechanisms daily with compressed air while lubricating mechanical parts; replace lubrication oil annually.

- Test safety devices weekly for proper functionality.

Esko

- Perform regular tool cleaning and inspection on a daily and weekly basis.

- Replace fuses and inspect electrical components during scheduled servicing.

- Utilize protective equipment when conducting maintenance tasks.

- Reset safety systems properly following repairs.

- Assign troubleshooting and repairs only to authorized personnel to avoid accidents or equipment damage.

ELITRON

- Design-focused tools ensure ease of maintenance for uninterrupted workflow.

- Follow manufacturer-recommended schedules for specific tool maintenance.

- Utilize robotics integrated into systems for enhanced precision and durability.

- Conduct regular inspections and service intervals as advised to maintain high performance standards.

TESEO

- Employ specialized tools such as Allen wrenches, deburring tools, and torque wrenches during maintenance or assembly tasks.

- Deburr cuts diligently to safeguard seals and simplify assembly processes.

- Inspect system joints rigorously for leaks during routine testing.

- Strictly enforce safety protocols, including pressure release procedures and use of protective gear during maintenance activities.

- Refer to technical support for repairs requiring expertise or addressing manufacturing defects.

Across all brands, some universal practices to extend tool life, maintain performance, prevent damage, and ensure safety include:

- Routine cleaning and lubrication to minimize wear and tear.

- Timely replacement of worn or damaged tools based on visual or mechanical indicators.

- Adherence to specific manufacturer maintenance schedules and safety guidelines.

- Proper alignment and handling during replacements to avoid equipment damage.

- Maintaining detailed records of servicing for operational tracking and troubleshooting.

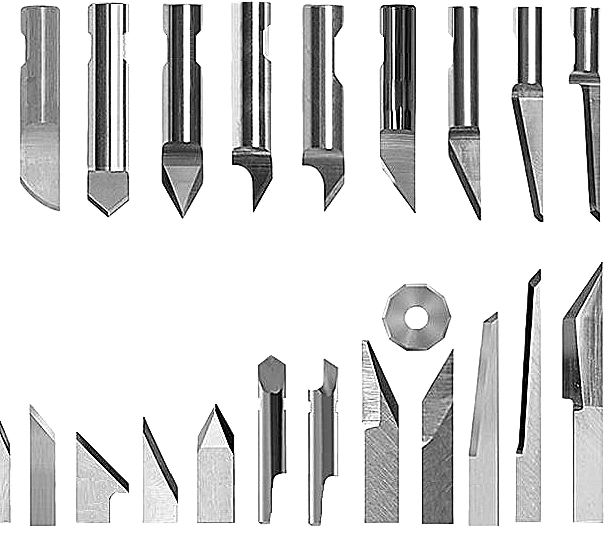

Shenzhen Oyea Machinery Co., Ltd. offers an all-encompassing ecosystem catering to ZUND, ATOM, COMELZ, Esko, ELITRON, and TESEO systems with hardware solutions, consumables, and customization options tailored for precise material processing industries.

Additionally, the company stands as a global frontrunner in manufacturing both standard and custom cutting knives that surpass OEM standards. Oyea’s cutting tools are readily accessible across Europe, the Americas, the Middle East, and Asia via efficient shipping networks complemented by exceptional customer service. Their products have earned trust in international markets including Germany, France, the UK, the USA, Russia, Vietnam, Thailand, Indonesia, South Korea, Japan, Italy, Australia, Malaysia, Canada, India, among others.

PREV : Colex T00505 Esko Kongsberg Bit-Mus06-4022-50 Zund R158 Router Bits Compatible And Equivalent NEXT : Messer Нож Scian Nóż Pisau Lama Lame Čepel Penge 잎 Lưỡi Dao Jwei/Jingwei Knife Blade