Key machine features that influence tooling efficiency and versatility

Multi-tool heads and modular cassettes

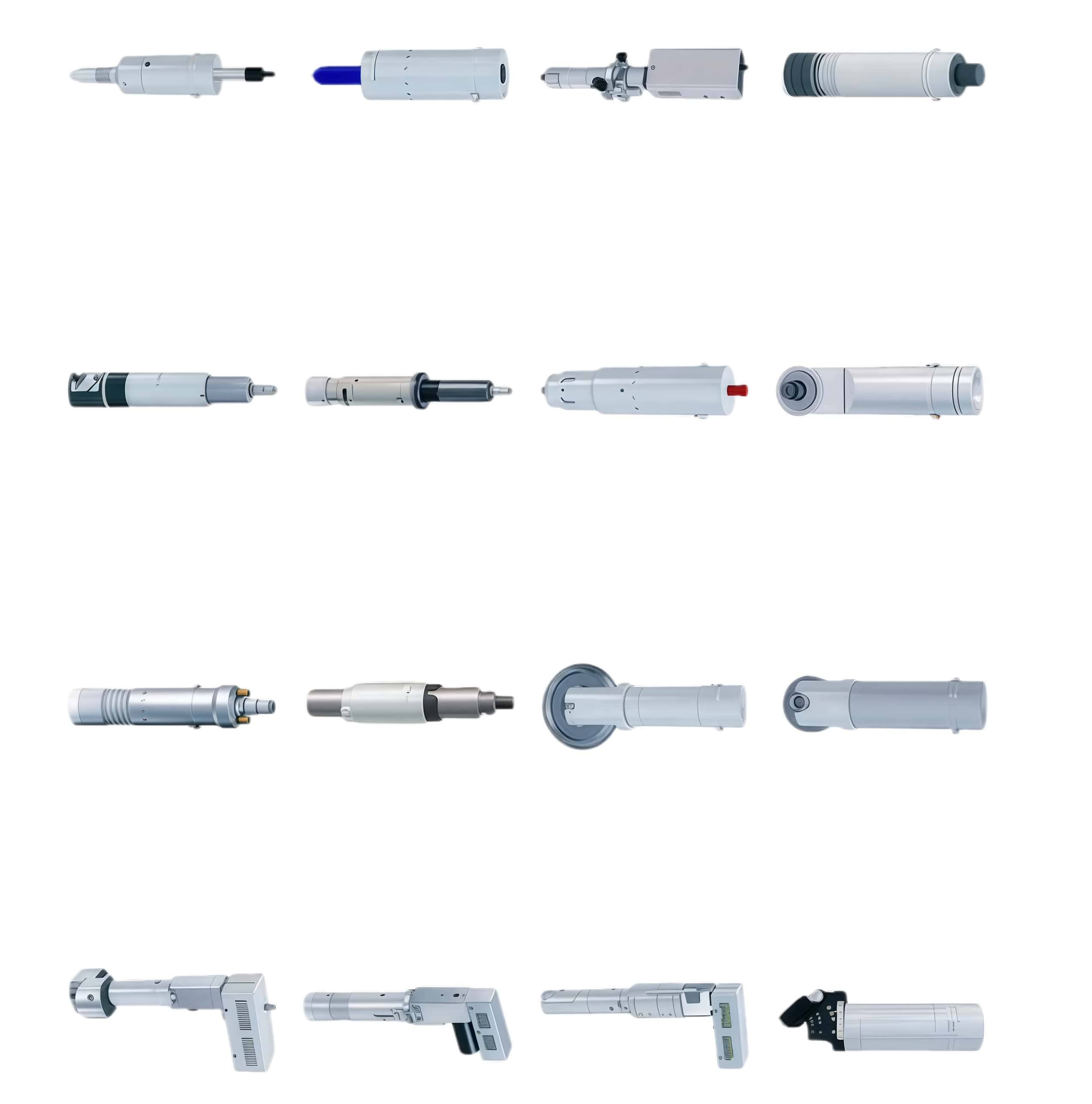

Modern flatbed cutting machines are often equipped with capabilities to carry several tools simultaneously, offering optimal flexibility for a diverse range of tasks. These tools may include vibrating knives for precise cuts, oblique knives for angled incision applications, round or rotary knives for circular or continuous cuts, punching tools for creating holes or perforations, milling spindles for more intricate or heavy-duty material removal, creasing wheels for folding or scoring tasks, marking pens for annotations or guides, and projectors or CCD cameras for registration and enhanced accuracy.

Furthermore, quick-change tool holders designed for 6 mm cylindrical shanks or similar setups streamline the process of switching between various blade types. This capability allows operators to adapt quickly to different jobs, improving workflow efficiency while minimizing downtime during transition phases.

Material hold-down and support system (vacuum technology with felt or mat bases)

Advanced vacuum table systems equipped with felt, rubber, or other specialized underlays play a critical role in maintaining material stability during operations. These surfaces not only ensure that flexible materials, sheets, or fabrics remain flat but also effectively prevent vibration, which could compromise precision during the cutting process.

The additional inclusion of an underlay serves as a vital sacrificial layer designed to absorb the cutting tool's penetration slightly beyond the material's surface. This prevents unintended damage to the cutter's machine bed while prolonging operational longevity and safeguarding tools against unnecessary wear.

Motion control and precision

Flatbed cutters rely heavily on CNC control systems and servo-driven mechanisms to deliver seamless and precise motion control. Typically, these systems enable contour-following at impressive speeds ranging from approximately 1200 mm/s to 2600 mm/s with exceptional repeatability of roughly ±0.05–0.1 mm. These characteristics are particularly important for maintaining accuracy across even the most intricate designs on digital knife tables.

Enhanced precision is further supported by CCD cameras and projectors, which enable registration to prints, pre-defined patterns, or leather nesting arrangements. This ensures flawless alignment of toolpaths to meet exacting production standards, especially for applications requiring fine detailing or alignment on pre-marked materials.

Practical considerations to select the right tools

1. Choosing the appropriate tool type based on material properties:

- For thinner, less resistant materials that require low cutting force, drag knives are typically sufficient.

- Oscillating tools are better suited for thicker or softer materials.

- Pneumatic oscillating tools or tangential cutting options excel when working with dense materials or multi-layer stacks due to their enhanced cutting power and control.

2. Selecting blade material and design according to job demands:

- For heavy-duty tasks or highly abrasive materials, solid carbide blades or those constructed from premium-grade tool steels are ideal due to their durability and long lifespan.

- Slender blade profiles are preferable for projects demanding intricate details, while sturdier geometries provide the necessary depth and resilience for more demanding cuts.

3. Adjusting machine parameters for cutting precision:

- Employ shorter stroke lengths and higher operational frequencies when aiming for clean, crisp edges on softer materials.

- Opt for longer strokes with slower travel speeds when tackling extremely thick or dense materials to achieve deeper penetration without sacrificing edge quality or tool stability.

By carefully balancing these functional aspects—tool selection, material support systems, motion control, and machine parameter adjustments—a cutting machine can become a highly efficient and versatile tool capable of delivering exceptional results across a diverse range of projects and material types.

PREV : Differences Between The Iecho E74 And E13 Blades NEXT : China Tungsten Carbide Blades And Knives Production Manufacturing Supply