|

Zund Module |

Overview |

Compatibility |

|

Laser Module LM |

LM is suitable for cutting the following materials with high precision: paper, PVC, polyester fabric applications. |

Compatible with G3 |

|

Marker Modules MAM |

MAM is used for marking, drawing of die-lines, seams, patterns, guidelines, skinning templates etc. One or two writing and drawing tools can be installed. |

Compatible with all drawing/plotting Zund Inserts |

|

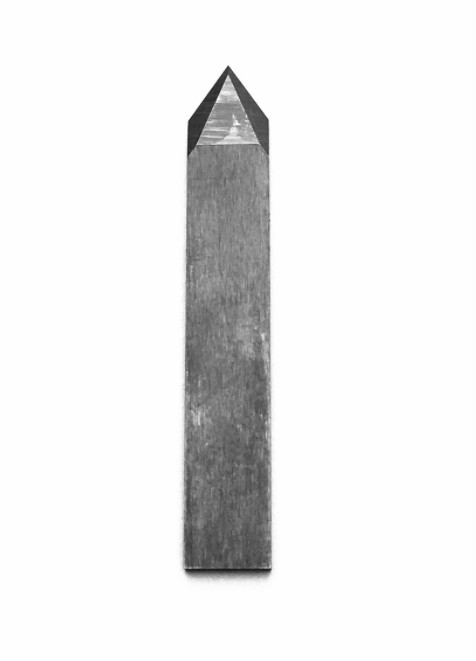

Punch Modules PM |

PM is suitable for piercing/penetrating leather, textiles, rubber or materials up to approx. 6 mm thick. Up to two tools plus a marking device or piercing needle can be installed at the same time. |

Compatible with S3, L3 |

|

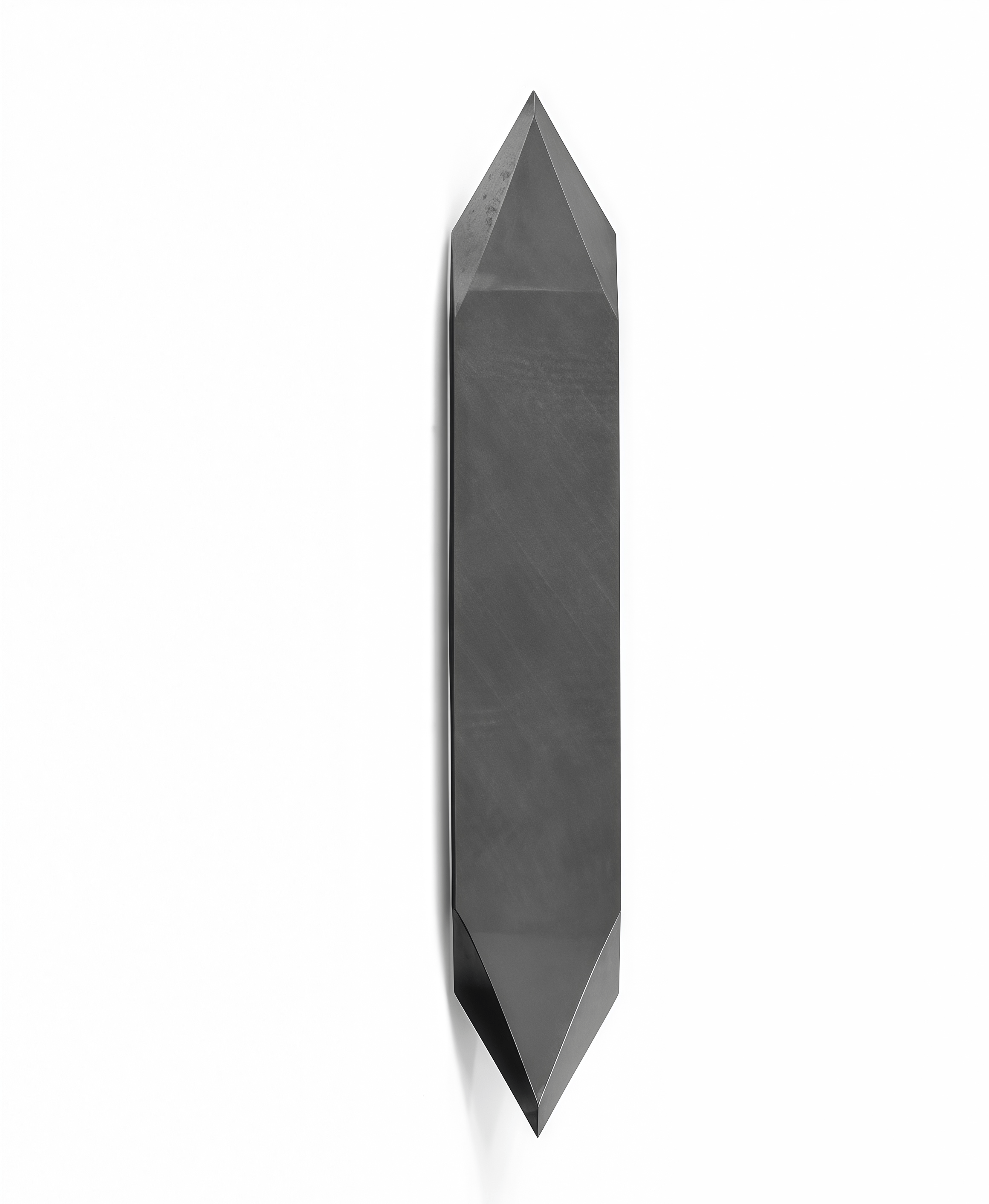

Router Modules RM |

Router Modules RM is applicable for milling, engraving and polishing of different types of plastic, aluminum, wood, composites and other dense materials. Maximum milling depth is 25 mm. Uses spindle power from 1 kW. Equipped with an active cooling system for heat removal and powerful exhaust for waste removal. |

Compatible with G3, D3 |

|

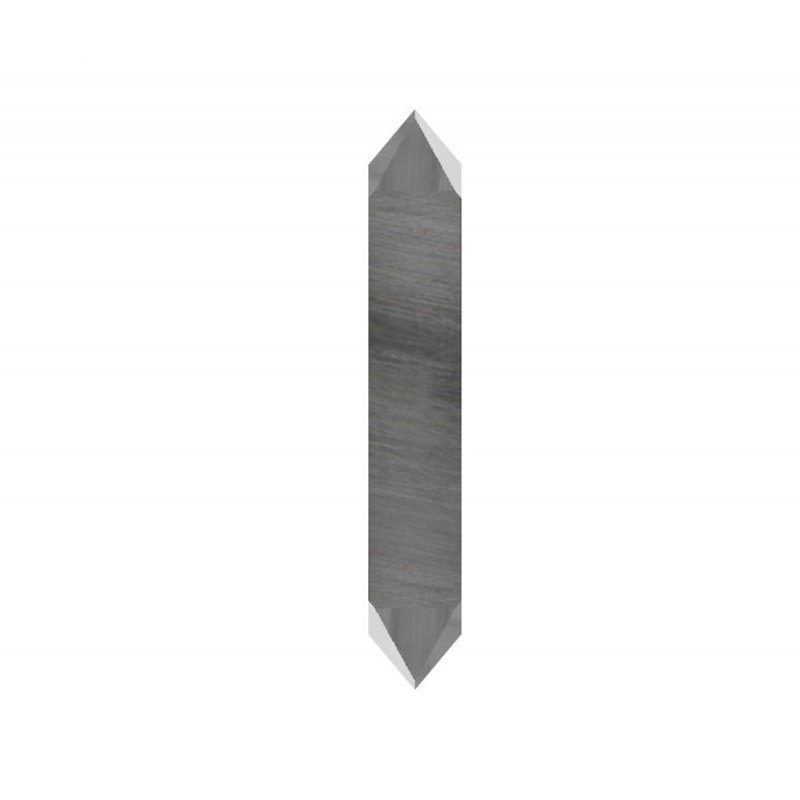

Universal Modules UM |

Universal Modules UM has two versions - one for speed, the other for power. Allows you to use the maximum number of popular tools, but no more than one at a time. Provides maximum possibilities in terms of the operations to be performed at minimum cost. Each tool can be equipped with an electric drive or with a more powerful pneumatic drive. |

Compatible with G3, D3 |

|

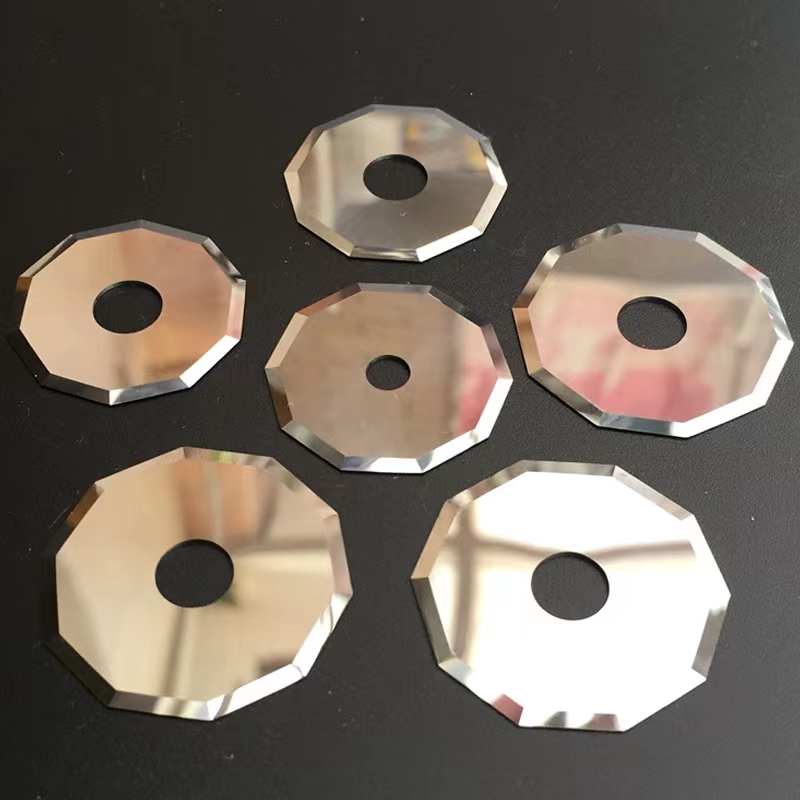

Kiss-cut Module KCM |

Kiss-cut Module KCM has very high cutting speeds, high precision and is suitable for cutting: self-adhesive vinyls and materials with a thickness of up to 1.5 mm. |

Compatible with S3 |

Each module is equipped with advanced technology that allows users to customize their cutting processes according to specific project demands, whether working with textiles, cardboard, foam, leather, or other materials. The modular nature of these tools ensures that they can be easily interchanged and adapted to handle even the most complex tasks with efficiency and accuracy.

In addition to their adaptable design, Zund Cutter Modules are built to deliver precise results while minimizing waste, contributing to both cost-effectiveness and environmental sustainability. Their user-friendly interface and compatibility with Zund’s software solutions make it simple to integrate them seamlessly into existing workflows, maximizing productivity without compromising quality.

Whether for industrial-scale manufacturing or intricate design work, the Zund Cutter Modules empower users to achieve unparalleled precision and flexibility, solidifying their position as a reliable choice for cutting-edge material solutions.

Shenzhen Oyea Machinery Co., Ltd. production Aristo Axyz Atom Benz Blackman & White Bullmer Comagrav CombiPro Data Technology DRD Dierre Dyss Ecocam Elcede Elitron Esko Kongsberg Gerber Graphtec Gunnar Haase iEcho Science & Technology JWei Kasemake Krause Kuris RuiZhou Ronchini Lasercomb Protek Marbach Mécanuméric Mimaki Misomex Multicam RolandSei Summa Valiani Wild Tungsten Steel Blades

Sold To Germany, France, The United Kingdom, Poland, The United States, Russia, Vietnam, Thailand, Indonesia, Singapore, The Netherlands, Switzerland, South Korea, Japan, Turkey, The Philippines, Hong Kong, Taiwan, Italy, Spain, Hungary, The Czech Republic, New Zealand And Other Countries Or Regions

PREV : What materials are best suited for the ZUND Z16 blades? Specifications and dimensions NEXT : Introduction Of The Performance Of Tungsten Steel Blades