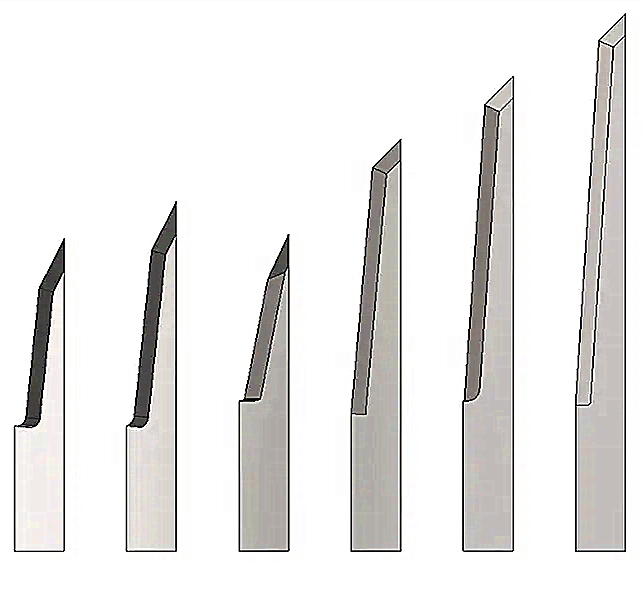

Analysis of the difference between of ZUND Z20 Z21 Z22 Z23 Z28 Z29 cutting machine systems tungsten carbide blades

Tungsten carbide blades for Zund cutting systems (Z20, Z21, Z22, Z23, Z28, Z29) differ primarily in cutting geometry, depth capacity, and material compatibility. These oscillating blades are designed for precision cutting in Zund G3, S3, L3, and D3 series digital cutters using Electric/Pneumatic Oscillating Tools (EOT/POT). Below is a detailed analysis:

![]()

Key Differences Summary

|

Blade |

Cutting Angle |

Max Depth |

Thickness |

Key Materials |

Specialization |

Source |

|

84° |

14.3 mm |

0.63 mm |

Corrugated cardboard, foam, ejection rubber |

Medium-density materials |

|

|

|

84° |

17.2 mm |

0.63 mm |

Leather, magnetic foil, polycarbonates |

Complex geometries, small radii |

|

|

|

63°/79° |

14 mm |

0.64 mm |

Corrugated plastic, rubber, sandblast film |

Angled cuts in rigid materials |

|

|

|

Not specified |

Not specified |

0.63 mm |

Industrial composites, thick plastics |

Heavy-duty applications |

|

|

|

Not specified |

Not specified |

0.63 mm |

Unspecified (likely dense materials) |

Specialized applications |

|

![]()

Design and Performance

o Both share an 84° cutting angle, but the Z21 offers greater depth (17.2 mm vs 14.3 mm) for thicker materials like leather hides and magnetic foil.

o The Z21’s finer geometry minimizes overcut, making it ideal for intricate patterns.

2. Z22 Distinctive Features

o Unique 63°/79° cutting angle for precision in rigid materials like corrugated plastic and rubber.

o Compatible with Esko and Summa systems, enhancing versatility.

3. Z23 Applications

o Designed for industrial-grade cutting of composites and thick plastics, though exact depth specifications are unlisted

o Limited data available, but thickness matches Z21/Z23 (0.63 mm). Likely optimized for niche materials or tool configurations.

![]()

Tool Compatibility

· Shared Compatibility: All blades work with Zund EOT/POT tools

· Material-Specific Pairing:

o Z20/Z21: Foam board, folding carton, polyester fabric.

o Z22: Corrugated plastic, rubber, sandblast film.

o Z23: Thicker composites (e.g., polycarbonates).

![]()

Material Considerations

· High-Density Materials: Z21 and Z23 are preferred for leather, polycarbonates, and industrial composites due to their deeper cut capacity

· Angled Cuts: Z22’s 63°/79° angle suits rigid materials requiring bevels or grooves

· Cost Efficiency: Z20 balances performance for mid-density materials like corrugated cardboard

![]()

![]()

For Z28/Z29, consult manufacturers directly for specifics, as public technical data is sparse. Prioritize Z21 for intricate designs or Z22 for angled cuts in rigid substrates.

Shenzhen Oyea Global sales: ensuring availability across Europe, the USA, the Middle East, and Asia with efficient shipping and customer service.Sold To Germany, France, The United Kingdom, Poland, The United States, Russia, Vietnam, Thailand, Indonesia, Singapore, The Netherlands, Switzerland, South Korea, Japan, Turkey, The Philippines, Hong Kong, Taiwan, Italy, Spain, Hungary, The Czech Republic And Other Countries Or Regions

PREV : Iecho Tools Compatible With Iecho Automatic Cutting Machines NEXT : What Are The Differences Between Zund Z6, Z10, Z11, Z44, Z46, Z101, Z102, Z103, And Z83 Blades