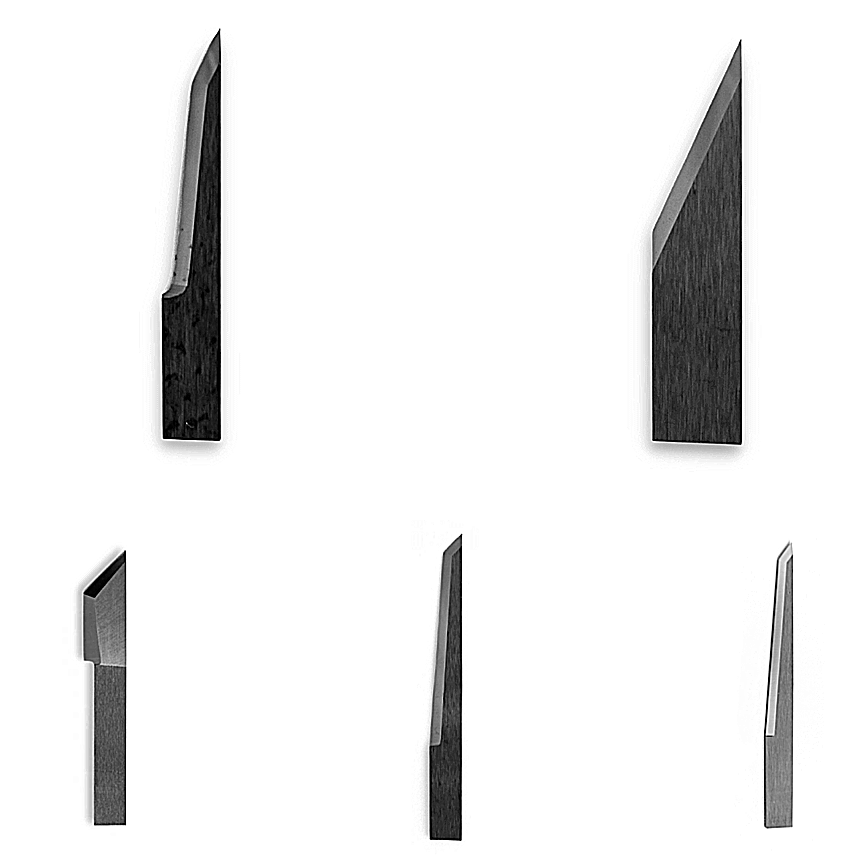

Best Blade For Zund G3 Cutter?Z17 Z21 Z22 Z23 Z26 Z28 Z46 Z33 Z35

The best blade for a Zund G3 cutter depends on the material you are cutting and the type of cut you need. The Zund G3 is a highly modular and flexible digital flatbed cutter that supports various blade types optimized for different applications.

Recommended Blade Types for Zund G3 Cutter

1. Drag Blades

· Z46 Carbide Drag Blade: This is a tungsten carbide flat drag blade with a 45° cutting angle and a maximum cutting depth of 20 mm. It is highly durable, offers cleaner and more precise cuts, and is suitable for a wide range of materials. It is compatible with the G3 cutter's UCT and SCT tool heads and is considered one of the best for heavy-duty cutting due to its tungsten carbide construction, which improves wear life up to 600% compared to standard steel blades.

· Z33 and Z35 V-Cut Blades: These blades have a 45° cutting angle and are designed for high-quality V-cuts in display boards and similar materials. They are made of carbide and suitable for cutting thicknesses up to 5 mm, offering fast processing speeds and high cut quality.

· Z22 Oscillating Blade: Recommended for cutting thicker display boards (up to 5 mm) with fine, precise contours. It is robust and designed for low overcut, suitable for intricate details. Compatible with the pneumatic oscillating tool on the G3 cutter.

2. Oscillating Blades

· Oscillating blades such as Z17, Z21, Z22, Z23, Z26, Z28, and others are compatible with the G3 cutter’s electric oscillating tool (EOT). These are suitable for soft to medium-density materials up to 3 mm thick, including cardboard, foam boards, leather, and rubber.

3. Rotary Blades

· For soft materials like fabrics, films, and thin papers, rotary drag knives are used. The G3 supports rotary blades with non-motor-driven tools like the wheel knife tool (28 mm diameter), which is cost-effective and precise.

Summary Table of Popular Blades for Zund G3

|

Blade Type |

Blade Model(s) |

Cutting Angle |

Max Thickness |

Material Suitability |

Notes |

|

Flat Drag Blade |

45° |

20 mm |

Wide range incl. thick materials |

Tungsten carbide, high durability |

|

|

V-Cut Blade |

45° |

5 mm |

Display boards, matboards |

Carbide, high quality V-cuts |

|

|

Oscillating Blade |

~45° |

5 mm |

Thick display boards |

Pneumatic oscillating tool, fine detail |

|

|

Oscillating Blades (various) |

Various |

Up to 3 mm |

Soft to medium density materials |

For cardboard, foam, leather, rubber |

|

|

Rotary Blade (Wheel Knife) |

28 mm diameter |

N/A |

Thin materials |

Soft fabrics, films, paper |

Non-motorized tool, cost-effective |

Conclusion

· For heavy-duty and thicker materials up to 20 mm, the Z46 tungsten carbide drag blade is the best choice for the Zund G3 cutter due to its durability and cutting performance

· For precision V-cuts in display boards or matboards, the Z33 and Z35 carbide V-cut blades are optimal.

· For intricate and thick material cutting with oscillating tools, the Z22 oscillating blade is recommended.

· For softer materials and thinner substrates, oscillating blades like Z17, Z21, and rotary blades provide efficient cutting.

Choosing the right blade depends on your specific material and cutting requirements, but these blades represent the best options tailored for the Zund G3 cutter system.

PREV : Iecho Tools Compatible With Iecho Automatic Cutting Machines NEXT : What Are The Differences Between Zund Z6, Z10, Z11, Z44, Z46, Z101, Z102, Z103, And Z83 Blades