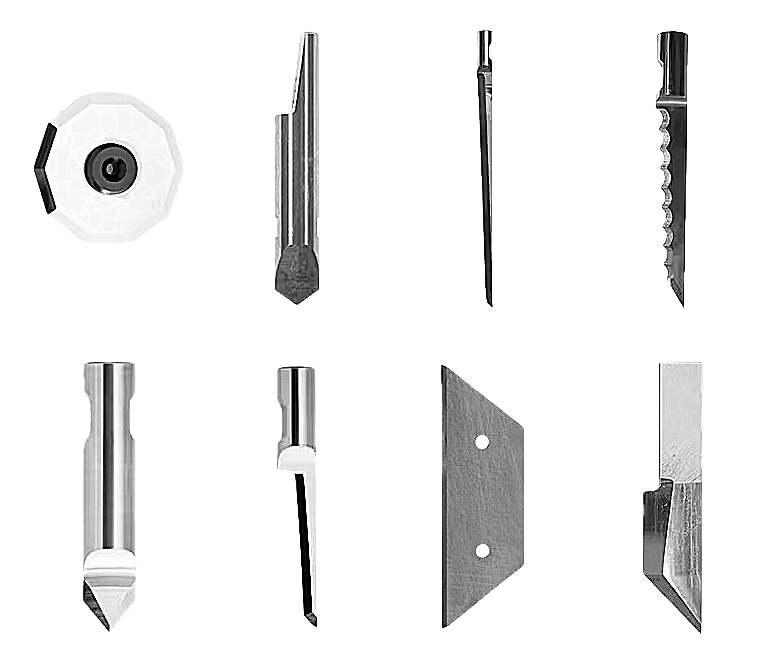

Common Knife Blades Used For Esko Kongsberg Precision Cutting Systems

Common blades used for Kongsberg Precision Cutting Systems include a variety of drag knives, oscillating knives, and specialized blades designed for different materials and cutting methods. Here is a detailed overview of the common blade types and their typical applications:

Common Blade Types for Kongsberg Systems

· Drag Blades (Single Edge)

Typically used for kiss cutting and through cutting of materials like vinyl, polyester, masking films, and thin plastics.

Examples include blades with 0.63 mm or 1.5 mm thickness and round or flat shanks.

Suitable for materials such as sandblast vinyls, reflective vinyls, cardstock, and pattern materials.

Example: Esko Kongsberg knife BLD-KC104 with a fine blade tip for small overcut and less stability, ideal for light materials.

· Oscillating Knives

Used for cutting thicker or more rigid materials such as corrugated board, foamboard, folding carton, felt, leather, textiles, and canvas.

Available in various shank sizes (6 mm round, 8 mm round) and blade angles (30°, 40°, 66°, 80°, 86.5°, 87.5°) depending on the cutting precision and material.

Examples include blades like SR-6150, SR-6223, SR-6303, and SR-6310 from OYEA, which are compatible replacements for Kongsberg oscillating knives.

· Corrugated Knives

Designed specifically for corrugated board cutting with single or double-edge blades.

Provide clean, efficient cuts on thick cardboard and similar materials.

· Tungsten Carbide Blades

Offer superior wear resistance and sharpness retention, essential for high-volume cutting.

Available as round shank blades for oscillating and drag knives.

These premium blades reduce downtime and improve cut quality but come at a higher cost.

· V-Notch and Specialty Blades

For specific applications such as cutting foam, rubber, or materials requiring detailed cuts.

Example: DF-570 V-Notch knife blade for strong durable cutting solutions.

Examples of Common Kongsberg Blade Models

|

Blade Model |

Cutting Method |

Recommended Materials |

Features |

|

Thru Cut, Drag Knife |

Corrugated board, foamboard, folding carton |

Versatile for thicker materials |

|

|

Thru Cut, Oscillating |

Corrugated board, felt, leather, display board |

Oscillating for clean cuts |

|

|

Thru Cut, Drag/Oscillating |

Self-adhesive vinyl, polyester, masking film |

Thin material precision cutting |

|

|

Thru Cut, Drag Knife |

Vinyl, polycarbonate, polyester |

Common for vinyl and films |

|

|

Thru Cut, Drag Knife |

Fabrics, textiles, canvas |

Textile and fabric cutting |

|

|

Oscillating Knife |

Folding carton, polyester film, leather, vinyl |

6 mm round shank, 5 mm cut length |

|

|

Oscillating Knife |

Corrugated board |

12 mm cut length, 6 mm round shank |

|

|

Oscillating Knife |

Foam, foam board, corrugated plastic |

20 mm cut length, 6 mm round shank |

These blades are designed to fit Kongsberg cutting systems precisely, ensuring optimal performance and minimal machine downtime.

Shenzhen Oyea Global sales: ensuring availability across Europe, the USA, the Middle East, and Asia with efficient shipping and customer service.Sold To Germany, France, The United Kingdom, Poland, The United States, Russia, Vietnam, Thailand, Indonesia, Singapore, The Netherlands, Switzerland, South Korea, Japan, Turkey, The Philippines, Hong Kong, Taiwan, Italy, Spain, Hungary, The Czech Republic And Other Countries Or Regions

Summary

Kongsberg Precision Cutting Systems commonly use a range of blades including:

· Single edge drag knives for vinyl and thin materials

· Oscillating knives for thicker and more rigid materials like corrugated boards and foam

· Tungsten carbide blades for enhanced durability and longevity

· Specialized blades like V-Notch and corrugated knives for specific cutting needs

Choosing the right blade depends on the material and cutting method required. Suppliers often offer compatible blades matching Esko/Kongsberg specifications to maintain precision and reduce wear

PREV : Summa Aristo Gerber Esko Roland Zund Knives And CNC Knife Blades Are Widely Sold And Distributed NEXT : Atom Kimla Polska Grupa Cnc Seron Tungsten Steel Blade Compatibility Replacement Applicable