How To Choose Zund Atom Summa Jwei Esko Iecho Blades For Cutting Leather Versus Foam

To choose blades for cutting leather versus foam using Zund, Atom, Summa, Jwei, Esko, and Iecho cutters, key considerations include the blade type, material compatibility, blade angle, cutting depth, and machine compatibility.

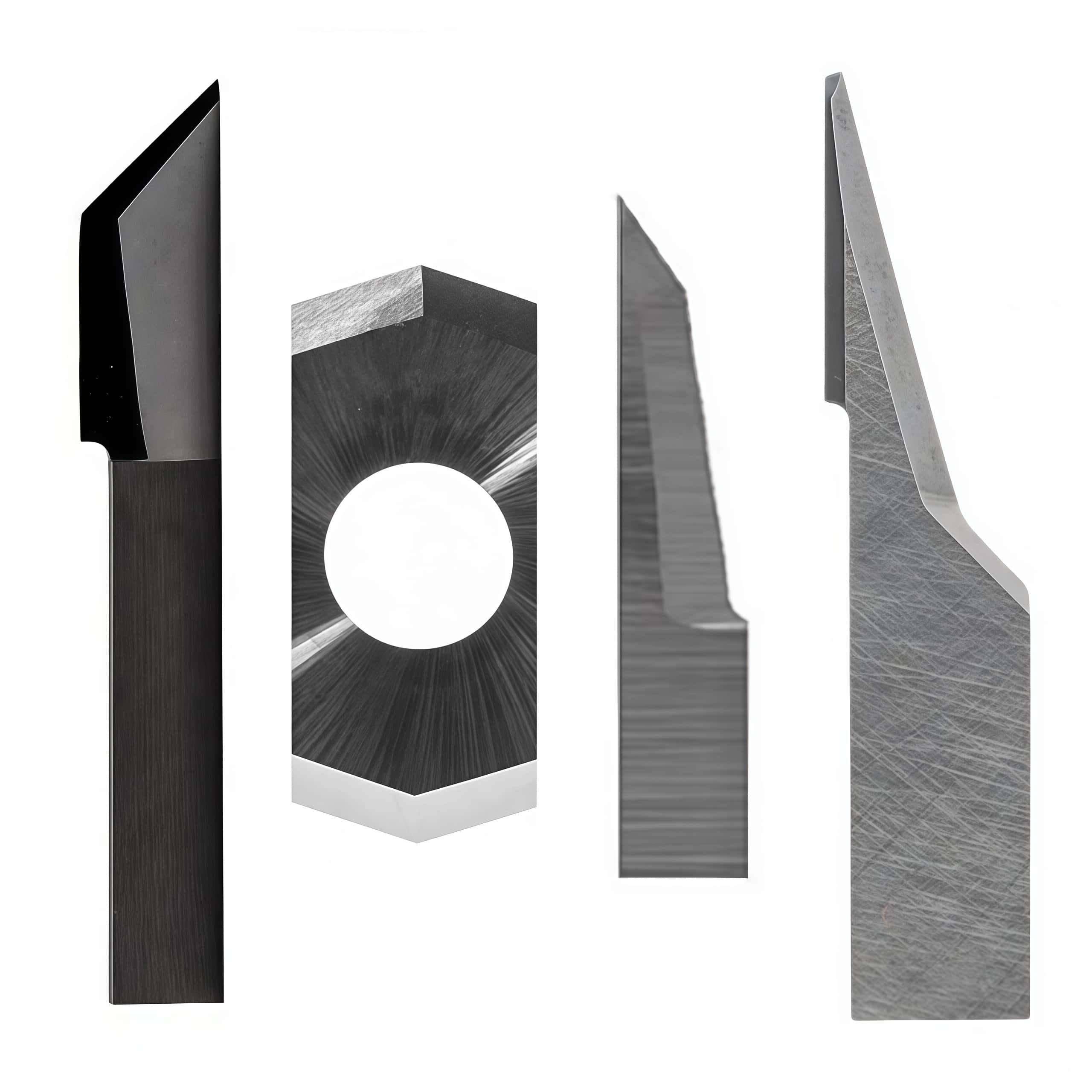

Key Blade Types by Material:

· Leather: Rotary blades and oscillating blades with sharper angles and tungsten carbide material are ideal for soft but tough materials like leather. Rotary blades (decagonal) allow smooth, pull-free cutting of leather. Oscillating blades offer precision on thicker or textured leather.

· Foam: Oscillating blades with flat or serrated edges are best for thicker and dense materials like foam or rubber. These blades move rapidly up/down to slice through fibrous or spongy materials cleanly.

Brand & Blade Examples:

· Zund: Versatile blades like Z60 oscillating blade (cutting angle ~81.5°, depth ~16.5 mm) work well for leather and foam. The Z50 rotary blade is specialized for soft, fibrous materials and suitable for leather.

· Summa: Drag blades with angles 36°-55° handle thin to medium materials. Oscillating blades are preferred for foam. Models like Summa 500-9807 offer heavy-duty cutting similar to Zund’s Z46.

· Atom: Tungsten carbide blades (e.g., ATOM 01030773) designed for leather with high durability and appropriate angles around 5°-15° are common.

· Jwei: Oscillating knives like J325 cut up to 17 mm thick materials including rubber and foam, offering good performance on leather too.

· Esko: Heavy-duty carbide oscillating blades (e.g., Esko BLD-SF346) suit both leather and foam.

· Iecho: Similar to Zund and Summa, offers oscillating and drag blades optimized for various materials including leather and foam.

Selection Guidelines:

1. Match blade type: Use rotary blades for thin, flexible materials such as leather (to cut without pulling), and oscillating blades for thick, dense foam.

2. Blade angle: Steeper angles (~45° or more) are better for thicker materials like foam, while lower angles (~30°-36°) work for thinner leather.

3. Material & hardness: Tungsten carbide blades prolong sharpness on tough materials like leather.

4. Cutting depth: Ensure blade max cutting depth exceeds material thickness (e.g., foam can be 10+ mm thick, leather generally thinner).

5. Compatibility: Confirm the blade is compatible with machine model and tool holder (e.g., Zund G3, Summa F series, Atom FlashCut).

Following these principles helps optimize cutting quality and blade longevity for leather versus foam across these brands and models

Shenzhen Oyea Machinery Co., Ltd. specializes in the production, manufacturing, and wholesale supply of high-quality blades compatible with renowned brands like Zund, Atom, Summa, Jwei, Esko, and Iecho. As a trusted provider, the company offers comprehensive OEM and ODM services, ensuring precision and efficiency in blade production for a diverse range of industrial applications. From factory-level manufacturing to large-scale supply solutions, their expertise caters to businesses looking for reliable and innovative cutting solutions.

PREV : Ножи для режущих плоттеров Summa D SUMMA T 391-231 391-360 391-358 390-534 390-560 390-550 390-551 NEXT : Using the Zund Digital Knife Cutter(一)