MultiCam CNC routers use a variety of router bits designed to mill and drill materials precisely. The router bits are rotary cutting tools fixed in a spindle that moves along the X, Y, and Z axes based on CAD/CAM tool paths. The MultiCam 3000 series router has a large work bed but limited head clearance, favoring workpiece thicknesses of 3 inches or less.

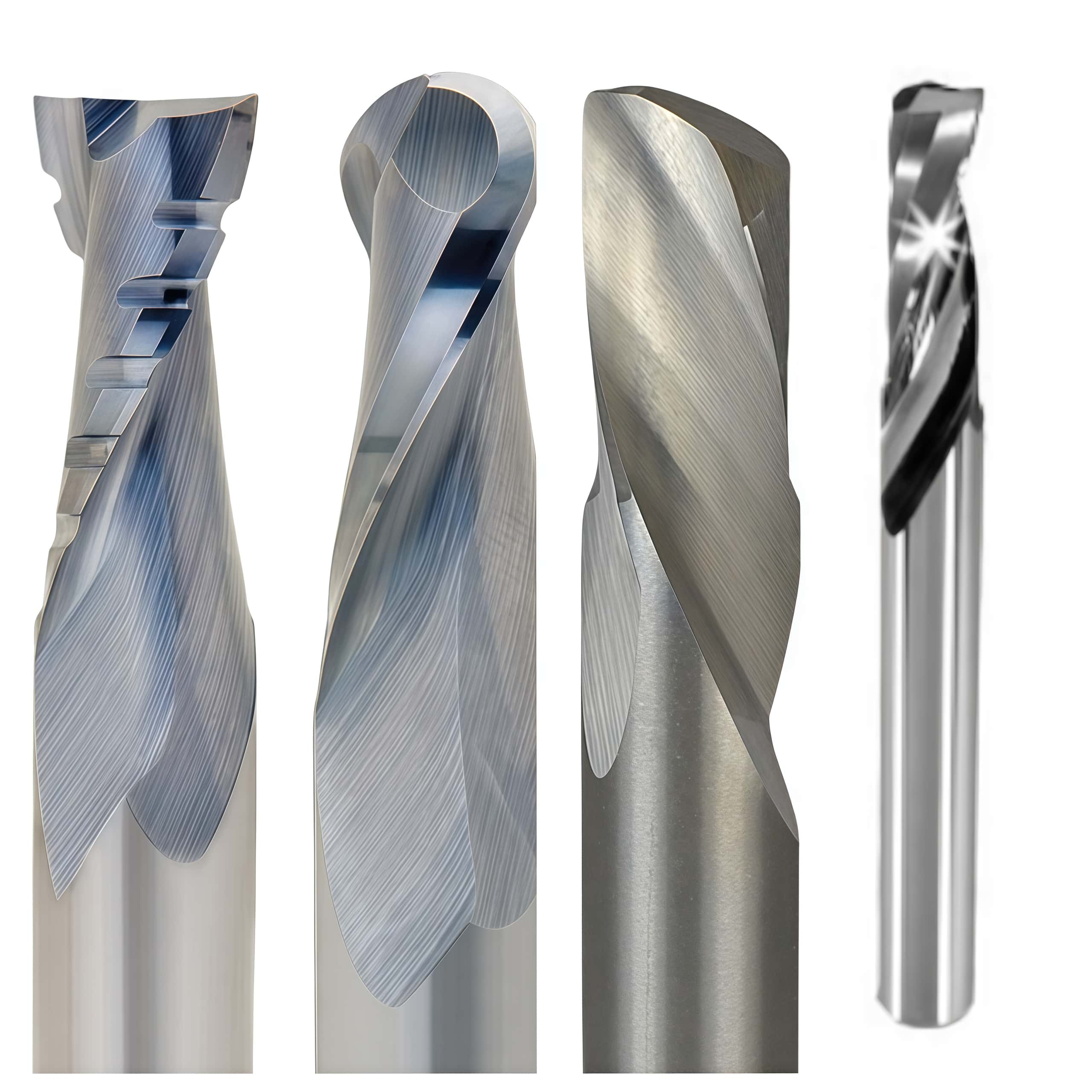

Key types of bits used with MultiCam CNC routers include:

- Up-Cut Spiral Bits: These bits pull chips upward, clearing debris efficiently. They are ideal for grooving and slotting thicker materials but may cause tearing on the top surface and require secure material holding.

- Down-Cut Spiral Bits: These bits push chips downward, providing clean top-edge cuts suitable for thin or flexible materials but can cause rubbing on the bottom.

- Compression Bits: Combining up-cut and down-cut flutes, these bits reduce edge chipping on laminated surfaces by pushing chips both ways.

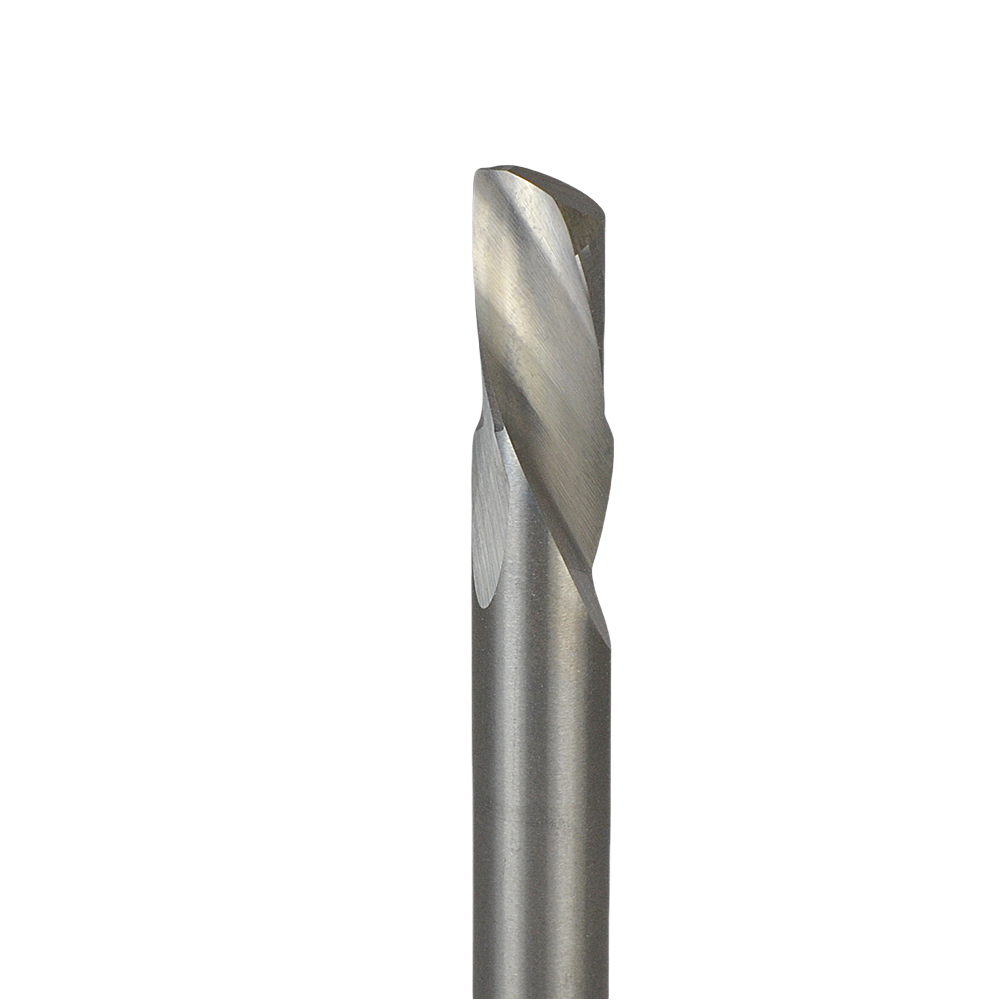

Bit flute count affects performance—typically, two flutes are common on MultiCam bits, with more flutes providing smoother finishes but less chip clearance.

Common bit material includes carbide for durability and precision, while polycrystalline diamond (PCD) bits are used for very hard or abrasive materials with exceptional tool life.

Typical MultiCam bits include ball nose bits for contouring and shaping, end mills for cutting and slotting, V-groove bits for engraving, and surfacing bits for flattening surfaces. Each bit type caters to specific materials such as wood, MDF, plastics, acrylic, and aluminum.

For best results, tool paths, feed rates, plunge rates, and bit types must be carefully selected according to material and cut requirements. MultiCam offers guidance on speeds and feeds for different materials.

In summary, choosing the right MultiCam router bit involves understanding bit type (up-cut, down-cut, compression), flute configuration, bit material, and matching these to the material being cut and the cutting operation desired for clean, efficient machining.

By prioritizing tailored solutions and embracing innovative manufacturing practices, Shenzhen Oyea Machinery demonstrates its commitment to meeting diverse customer demands. Its focus on building sustainable business partnerships and achieving excellence in production standards continues to set new benchmarks within the industry.

PREV : Ножи (Лезвия) для режущих плоттеров Iecho JWei RuiZhou NEXT : Esko Kongsberg Zund Bullmer Premiumcut Lectra Carbide Blades Pvd Coatings