Common Knife Blades Used For Summa Cutting Systems | Digital Cutter | Flatbed Cutter For Sale Shop

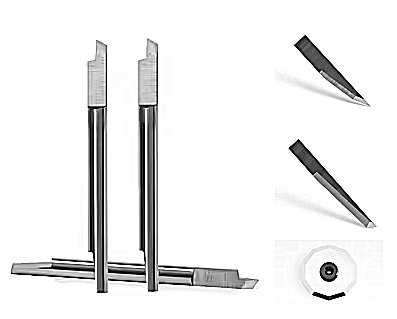

Common knife blades used for Summa cutting systems, including digital cutters and flatbed cutters, come in various types and angles tailored for different materials and cutting precision. Here is a detailed overview:

Types of Summa Knife Blades

1. Drag Knife Blades

· These blades swivel around corners while staying in contact with the material, suitable for general-purpose cutting.

· Common angles include:

o Standard 36° Blade: Ideal for cutting normal to thin vinyls and masking films.

o Rhinestone 50° Blade: Used for more detailed cuts.

o Sandblast 60° Blade: Used for tougher materials, requires a special holder.

· Drag blades fit in standard holders like Summa 391-332 or special holders depending on the blade type.

2. Tangential Knife Blades

· These blades lift and rotate for precise orientation, providing higher cutting accuracy.

· Common blade angles:

o 36° Standard Tangential Blade (Summa 390-534): Suitable for soft materials like vinyl, magnetic foil, and polyester fabric up to 0.25 mm thick.

o Double Edge 36° Blade

o Double Wedge 45° Blade

o Sandblast 60° Blade: For cutting thicker and tougher materials such as sheets, banners, and polyester fabrics up to 1.20 mm thick.

· Tangential blades are used in Summa's tangential modules and holders.

3. Specialty Blades

· 35° Vinyl Cutter Blade: Made from 13% cobalt ultra-fine grain carbide, designed for delicate, thin films/media (1-2 mil thick), compatible with Summa D-Series cutters.

· Oscillating Knife Blades: Used for intricate details and cutting thick materials like foam and rubber; blades such as Summa 500-9810, Summa 500-9807 are examples designed for oscillate cutting with minimal overcut and robust tips.

· Other blades include V-Cut blades, perforation blades, kiss-cut blades, and creasing tools, often used in flatbed cutting systems for specific applications like angled cuts, tear-off lines, or scoring.

Blade Materials and Features

· Carbide Blades: Extremely durable, suitable for tough materials.

· Steel Blades: More affordable but wear out faster.

· Coated Blades: Some blades have coatings like titanium to extend life and reduce friction.

Blade Selection Considerations

· Choose the blade angle based on material thickness and type:

o Lower angles (30°-45°) for thin, delicate materials.

o Higher angles (60°+) for thicker, tougher materials.

· Ensure blade compatibility with your Summa cutter model and holder type.

· Adjust cutting force and offset settings when changing blade angles to maintain cut quality.

Popular Summa Blade Models

|

Blade Type |

Angle |

Material/Application |

Notes |

|

Standard Drag Knife |

36° |

Vinyl, soft materials |

Fits standard holder 391-332 |

|

Rhinestone Drag Knife |

50° |

Detailed cuts |

Fits standard holder 391-332 |

|

Sandblast Drag Knife |

60° |

Tough materials like banners, polyester |

Requires special holder 391-363 |

|

Standard Tangential |

36° |

Soft materials, vinyl, magnetic foil |

Summa 390-534, fits tangential holders |

|

Double Edge Tangential |

36° |

Precision cutting |

Summa 390-551 |

|

Double Wedge Tangential |

45° |

Medium thickness materials |

Summa 390-560 |

|

Sandblast Tangential |

60° |

Thick, tough materials |

Summa 390-550 |

|

35° Vinyl Cutter Blade |

35° |

Thin, delicate vinyl films |

Summa D-Series compatible |

|

Oscillating Blades |

Various |

Foam, rubber, intricate detail |

Examples: Summa 500-9810, Summa 500-9807 |

Summa blades are available from Shenzhen Oyea Machinery Co., Ltd distributors and come in bulk quantities for replacement. They are precision-made to fit Summa cutters and provide long-lasting sharpness, often requiring adjustments in downforce for optimal performance.

In summary, Summa cutting systems use a variety of drag and tangential knife blades with angles typically ranging from 35° to 60°, made from carbide or steel, and designed for specific materials and cutting needs. Choosing the right blade depends on the material thickness, type, and desired cut precision.

PREV : Ножи для режущих плоттеров Summa D SUMMA T 391-231 391-360 391-358 390-534 390-560 390-550 390-551 NEXT : Using the Zund Digital Knife Cutter(一)